Carburized steel component excellent in low-cycle bending fatigue strength

A bending fatigue strength and carburizing steel technology, applied in the field of carburizing steel components, can solve the problem that the low cycle bending fatigue strength does not reach the level of low cycle bending fatigue strength, and achieve the effect of reducing CO2 emissions and improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0150] Next, examples of the present invention will be described, but the conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the examples of conditions.

[0151] In the present invention, various conditions can be adopted within the scope of achieving the object of the present invention without departing from the gist of the present invention.

[0152] (Example)

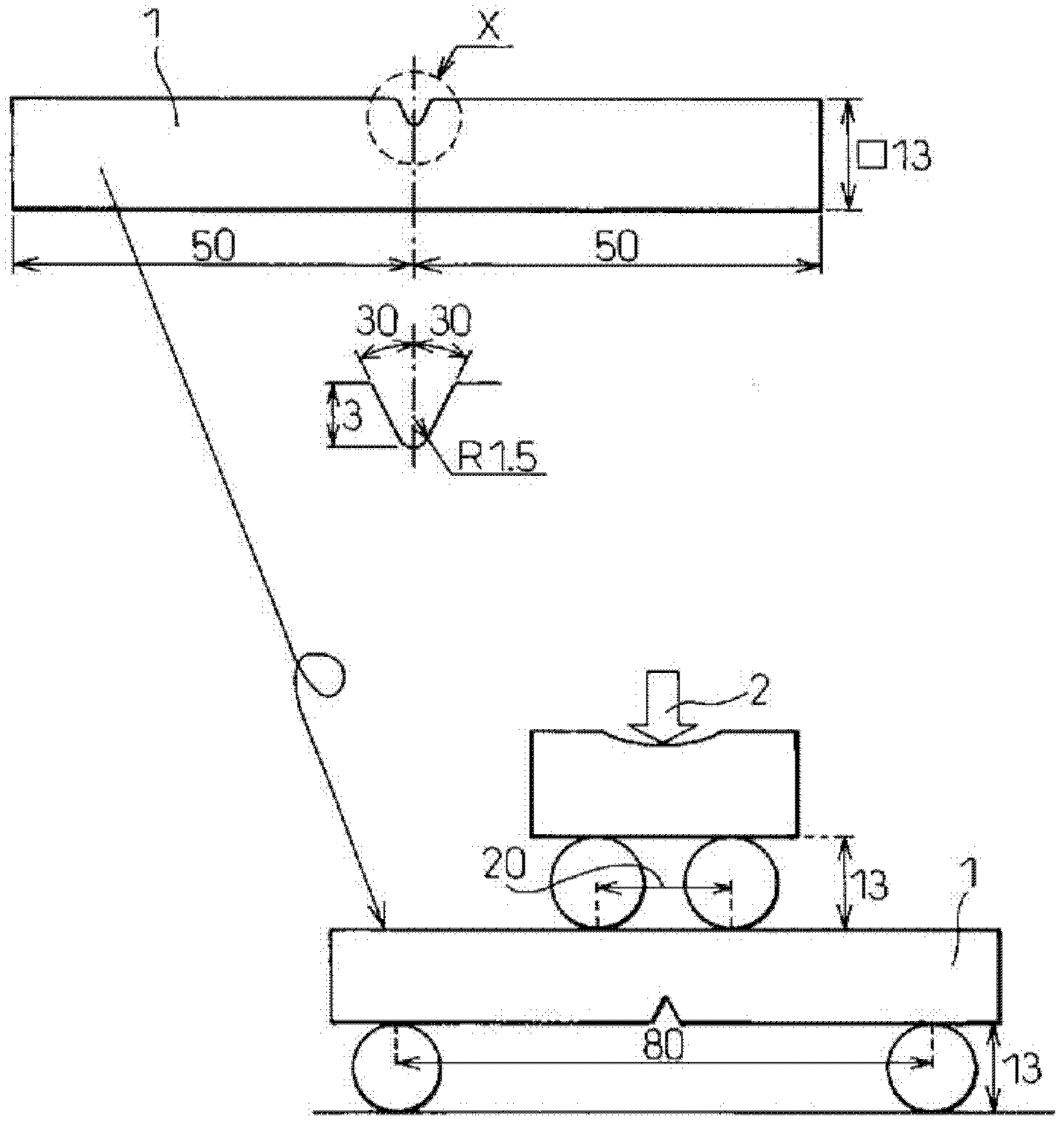

[0153] Steel materials having the composition shown in Table 1 and Table 2 were forged and stretched, and then soaked and normalized to produce rough-machined test pieces for low-cycle bending fatigue tests and rough-machined test pieces for wear tests.

[0154]

[0155]

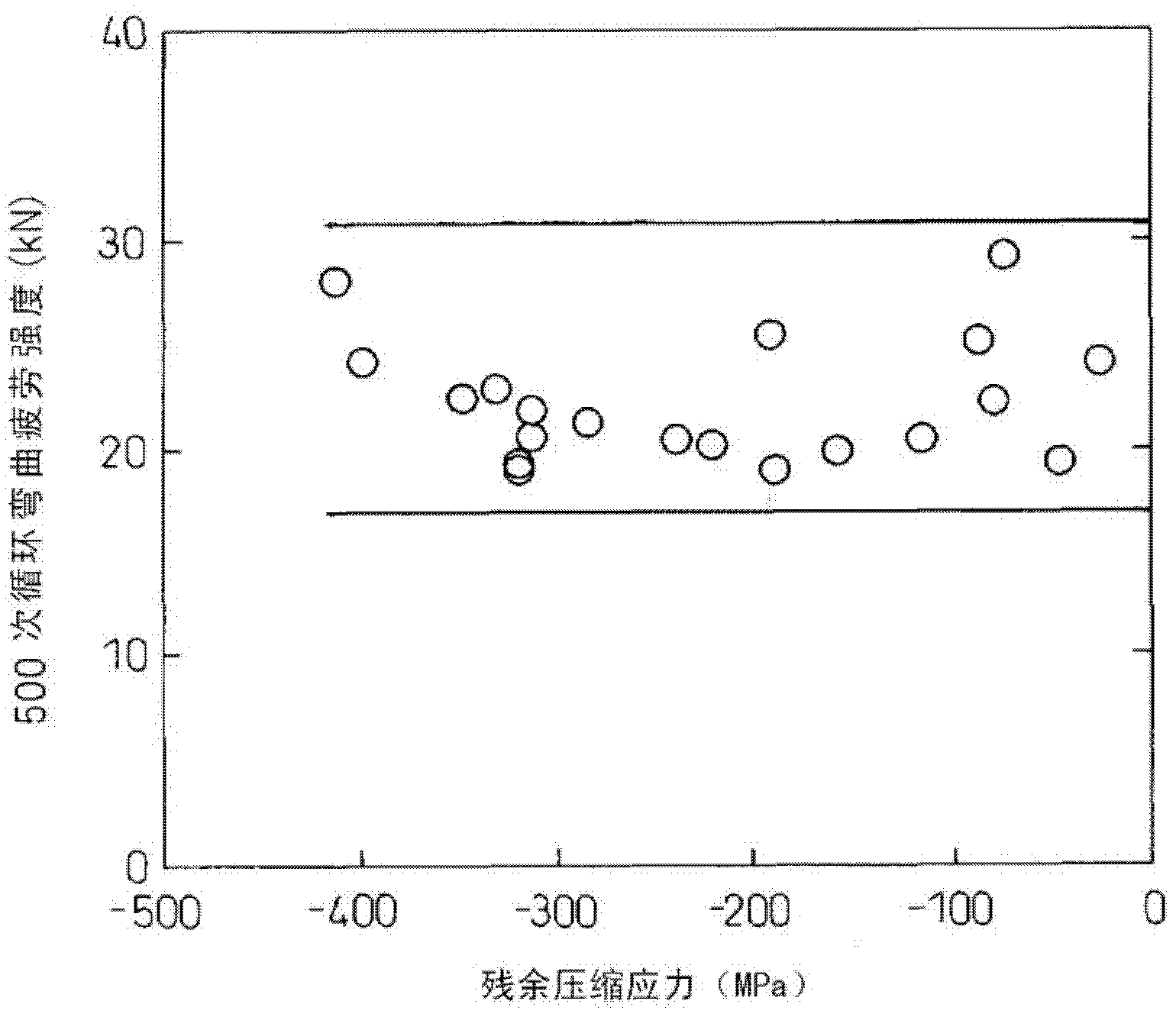

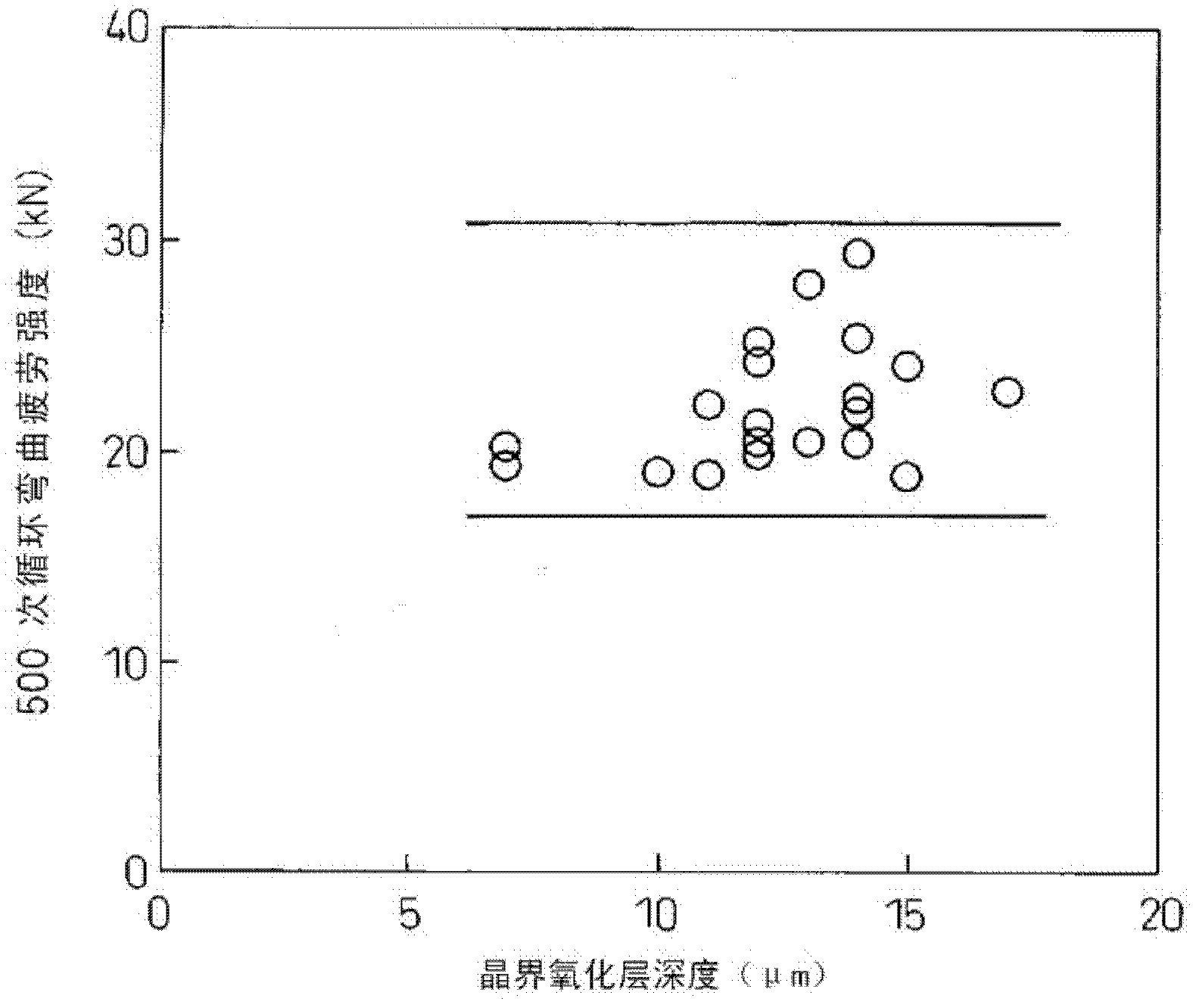

[0156]The rough machining test pieces of Test No.1-21 (Invention Example), Test No.23-25 (Comparative Example) and Test No.28-44 (Invention Example) were carried out for 930 hours in a reforming gas carburizing furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com