Mechanical horizontal steel wire rope bending fatigue testing machine and mechanical rotation driving device

A technology of bending fatigue and slewing drive, which is applied to the transmission device, gear transmission device, and the use of stable bending force to test the strength of materials, etc. It can solve the problems of large inertial impact force, lack of test data, and large space occupation, and achieve rigidity And the effect of high strength, strong versatility, and accurate swing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

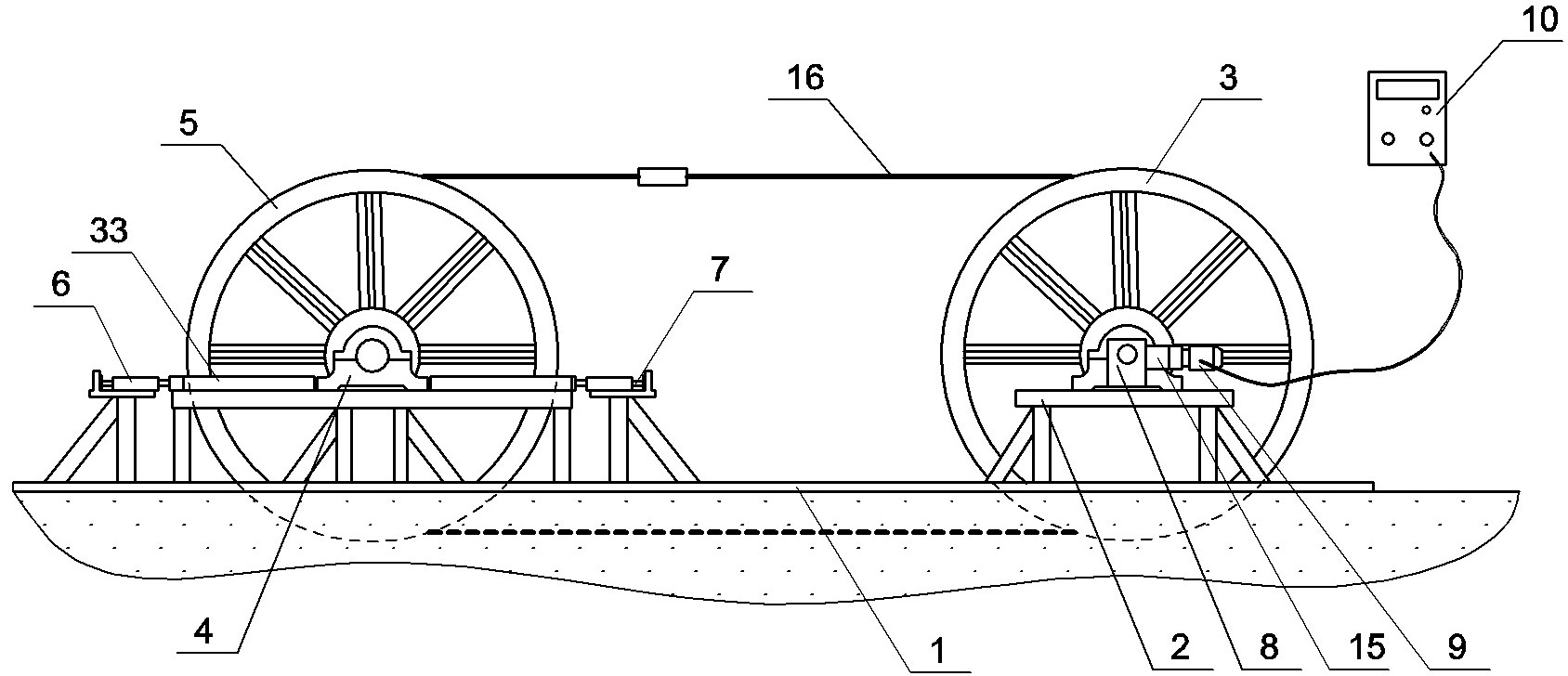

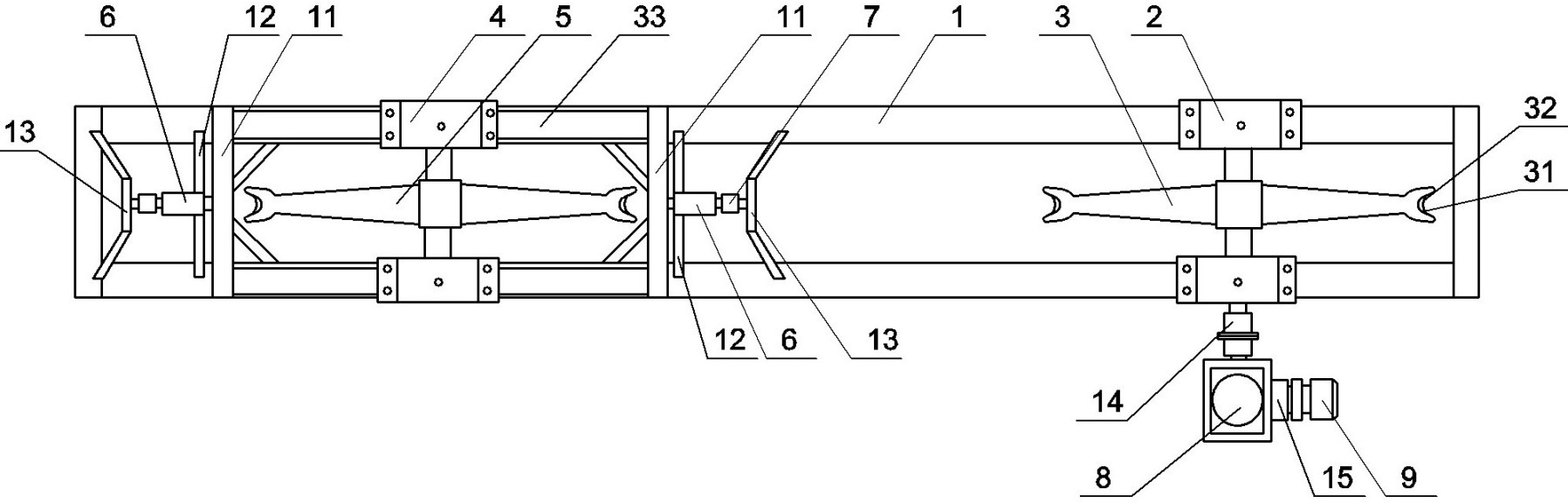

[0040] Embodiment one: see figure 1 , figure 2 , Figure 6 , Figure 7 and Figure 8 , a mechanical horizontal steel wire rope bending fatigue testing machine, a rectangular foundation pit is built with concrete on the ground, a base 1 is fixed around the rectangular pit groove, a bearing frame 2 is fixed at one end of the base 1, and a bearing frame is fixed 2 is equipped with a driving wheel 3, the other end of the base 1 is provided with a movable bearing frame 4 that can translate left and right, an experimental wheel 5 is installed on the movable bearing frame 4, the diameter of the driving wheel 3 is equal to that of the experimental wheel 4, and the driving wheel 3 Liners are respectively sleeved in the grooves of the test wheel and the test wheel 4. Parts of the two wheels go deep into the pit, so that the center of gravity and height of the whole testing machine are lowered, which is stable and reliable.

[0041] The bases on the left and right sides of the test...

Embodiment 2

[0046] Embodiment 2: The accompanying drawings are not drawn, and the content is basically the same as Embodiment 1. The difference is that the input shaft is connected with a common motor, and the output shaft of the motor is connected with the input shaft after passing through a hardened reducer.

Embodiment 3

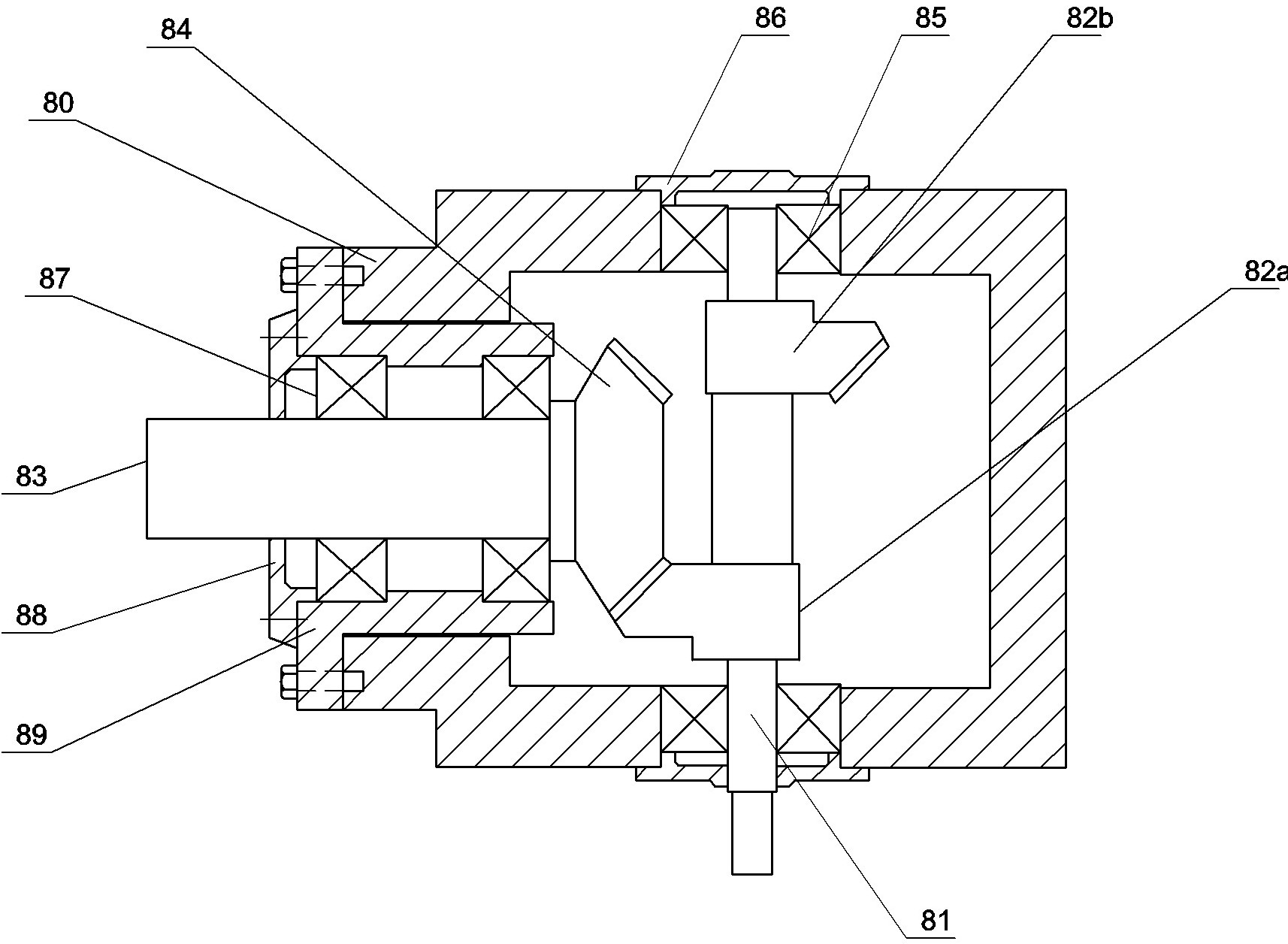

[0047] Embodiment three: see image 3 , Figure 4 or Figure 5 , a mechanical rotary drive device suitable for the mechanical horizontal wire rope bending fatigue testing machine described in Embodiment 1, comprising a transmission box 80, an input shaft 81 and an output shaft 83 are vertically installed on the transmission box 80, and the inner end of the output shaft 83 is installed There is a driven bevel gear 84, and the two ends of the inner side of the input shaft 81 are respectively equipped with driving bevel gears 82a and 82b, and the two driving bevel gears 82a and 82b are provided with a part of the arc surface with bevel teeth 17 ( Figure 5 Including part of the bevel teeth 17 and part of the smooth surface 18 without bevel teeth at the same time), and the two driving bevel gears 82a and 82b are symmetrically distributed to the center (that is, either of the two driving bevel gears 82a and 82b rotates 180 degrees along the axis alone After being symmetrical with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com