Reinforcing cord for rubber reinforcement and rubber product including the same

a technology of reinforcing cords and rubber products, applied in the direction of yarns, textiles and papermaking, etc., can solve the problems of deterioration of performance, separation between reinforcing fibers and rubber matrix, deterioration of strength, etc., and achieve excellent dimensional stability, high bending fatigue resistance, and high strength. the effect of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

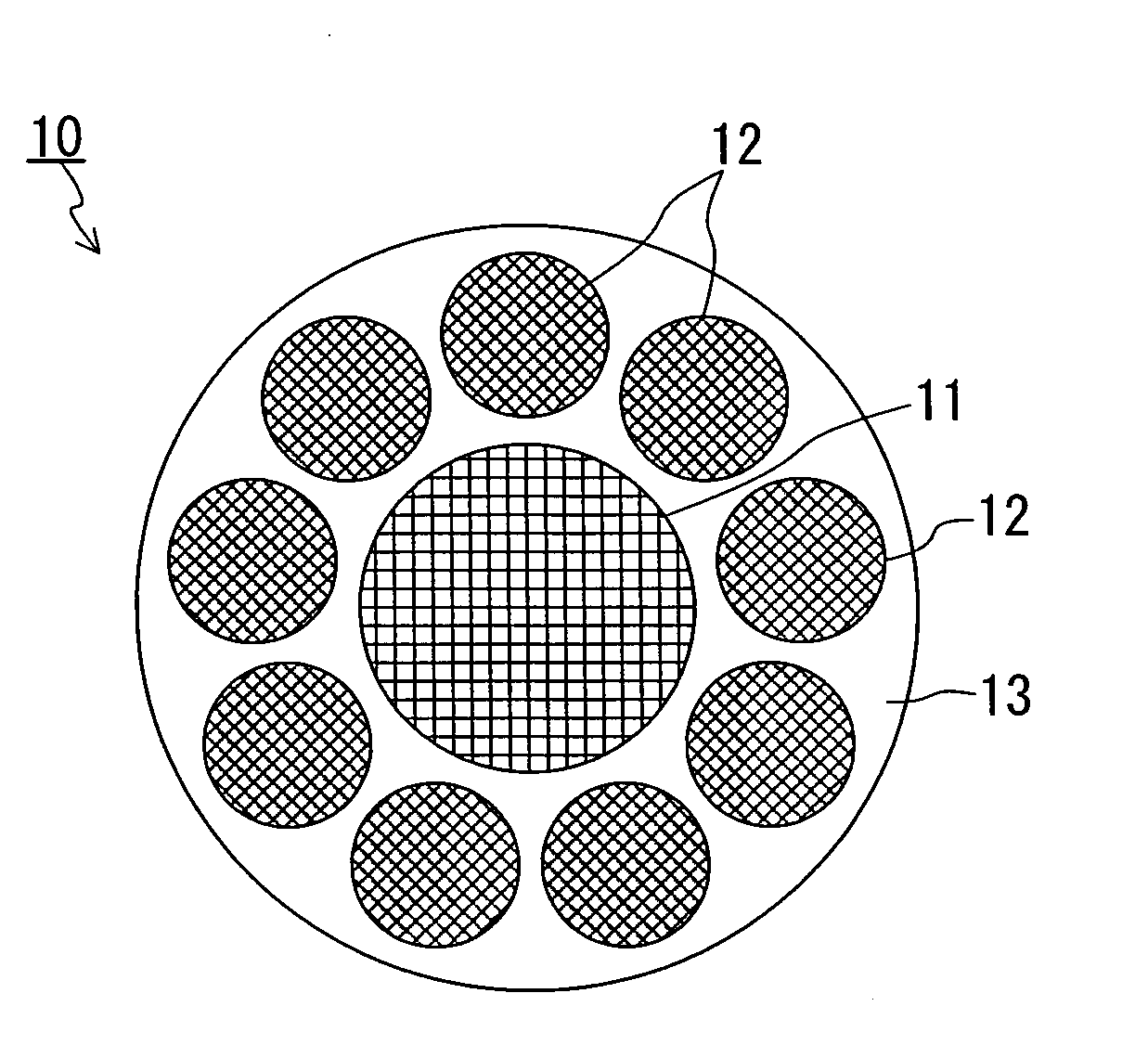

[0013] In Embodiment 1, the description is directed to a reinforcing cord for rubber reinforcement of the present invention. A reinforcing cord for rubber reinforcement of the present invention includes reinforcing fibers. The reinforcing fibers include polyarylate fibers and a plurality of strands (outer strands) that are arranged around the polyarylate fibers. The outer strands include fibers (hereinafter may be referred to as “second fibers” in some cases) other than polyarylate fibers.

[0014] The polyarylate fibers are wholly aromatic polyester fibers. They can be obtained through polycondensation of dihydric phenol (for example, bisphenol A) and aromatic dicarboxylic acid (for example, phthalic acid or isophthalic acid).

[0015] Preferably, the second fibers are fibers whose flexibility in bending is higher than that of the polyarylate fibers. Examples of the second fibers to be used herein include glass fibers, polyparaphenylene benzobisoxazole fibers, carbon fibers, aramid fib...

embodiment 2

[0032] In Embodiment 2, the description is directed to a rubber product of the present invention. The rubber product of the present invention includes at least one reinforcing cord for rubber reinforcement described in Embodiment 1. This reinforcing cord for rubber reinforcement may be a rope structure. Furthermore, a plurality of reinforcing cords for rubber reinforcement may be arranged and embedded in the shape of a sheet.

[0033] The rubber product of the present invention is not particularly limited as long as it is a rubber product reinforced effectively with the reinforcing cord for rubber reinforcement. Typical examples of the rubber product of the present invention include rubber belts such as a toothed belt and a move belt, and a rubber crawler.

[0034] In the rubber product of the present invention, the ratio of the reinforcing cord for rubber reinforcement to the rubber product is approximately 10 to 70 wt. %, for example.

example

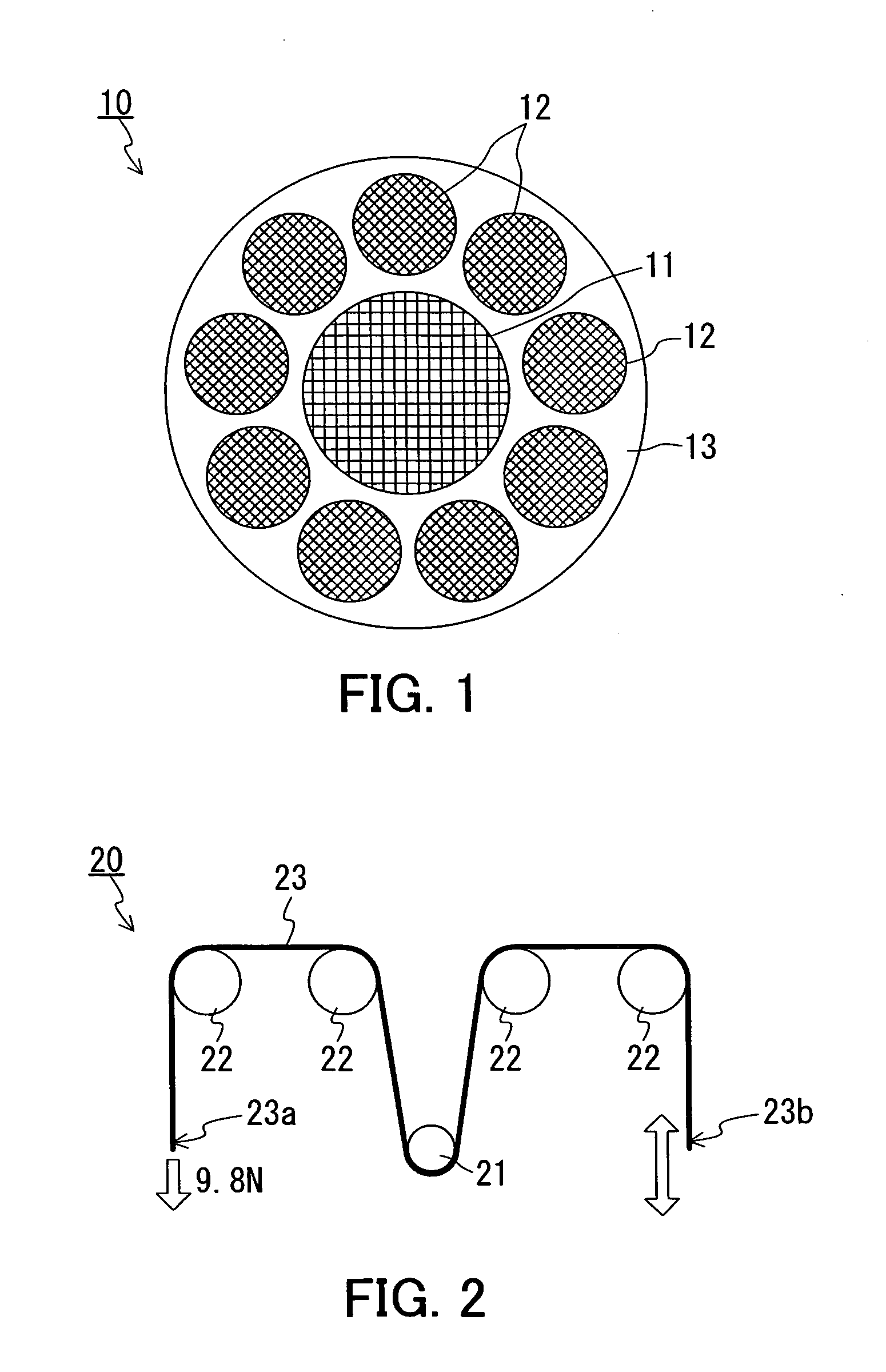

[0035] Hereinafter, the present invention is described further in detail using examples. In the examples, reinforcing cords for rubber reinforcement of the present invention and comparative examples were produced, and then the characteristics thereof were evaluated.

Sample 1

[0036] A reinforcing cord for rubber reinforcement of the present invention was produced by the following method. First, a resorcinol-formaldehyde condensate (with a solid content of 8 wt. %), vinyl pyridine-styrene-butadiene latex (with a solid content of 40 wt. %), and CSM (with a solid content of 40 wt. %) were mixed together in such a manner as to have a solid content mass ratio of 2:13:6. Thus, a RFL treatment solution was prepared. This RFL treatment solution was applied to a strand (with a diameter of approximately 0.8 mm; a non-twisted product) formed of polyarylate fibers (with an elastic modulus of 106 GPa and a density of approximately 1.41 g / cm3; Vectran (Trade Name); manufactured by KURARAY CO., LT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com