Tubular anti-flaming aramid fiber fabric lamination conveyor belt for coal mine

A conveyor belt and aramid fiber technology, applied in the field of flame retardant conveyor belts, can solve the problems of large diameter requirements of the driving drum, the weight of the steel wire rope belt, and the easy corrosion of the steel wire rope, so as to achieve the improvement of the mixing process, the strong pipe forming ability and the dynamic low heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

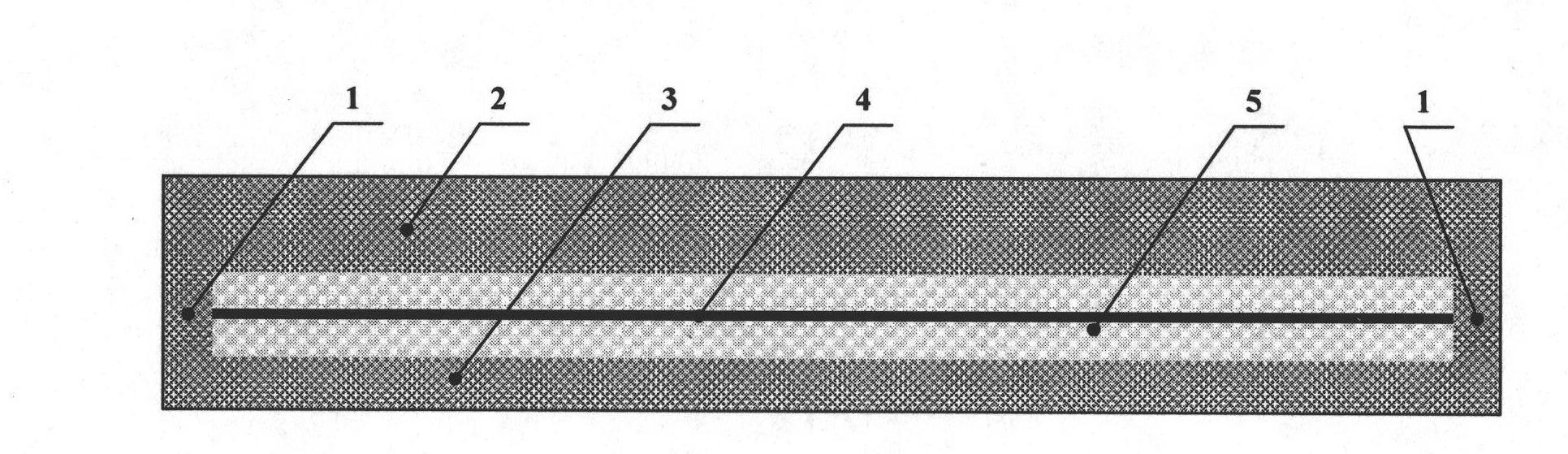

[0065] Such as figure 1 As shown, the present invention includes an edge glue 1 , an upper flame-retardant covering glue layer 2 , a lower flame-retardant covering glue layer 3 , an aramid fiber skeleton layer 4 , and a flame-retardant adhesive glue layer 5 . The aramid fiber skeleton layer 4 is bonded with the upper flame-retardant covering adhesive layer 2 and the lower flame-retardant covering adhesive layer 3 through the flame-retardant adhesive adhesive layer 5 to form a whole. The aramid fiber skeleton layer 4 adopts DP2500 diameter straight weft aramid fiber canvas, and its single layer strength is 2500N / mm.

[0066] Flame-retardant adhesive layer compound formula, its proportion by weight:

[0067] 50 parts of natural rubber, styrene-butadiene rubber: 30 parts, butadiene rubber: 20 parts;

[0068] Zinc oxide: 8 parts, magnesium oxide: 3 parts;

[0069] Stearic acid: 2 parts,

[0070] Accelerator CZ: 1.5 parts, Accelerator DM: 1.2 parts;

[0071] Flame retardant ta...

Embodiment 2

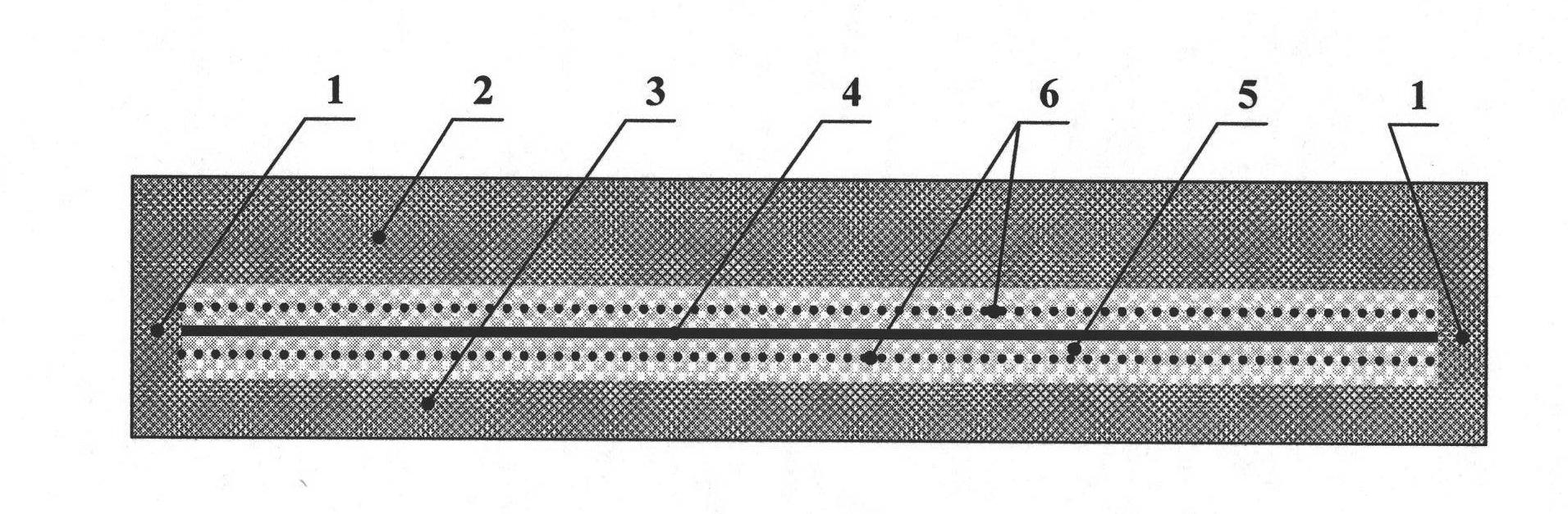

[0097] Such as figure 2 As shown, the upper and lower buffer layers 6 are arranged on the upper and lower sides of the aramid skeleton layer 4, between the aramid skeleton layer 6 and the buffer layer 6, the buffer layer 6 and the upper flame-retardant covering rubber layer 2, and the lower flame-retardant covering rubber layer 3 Bonded into a whole by flame-retardant adhesive glue layer 5 between them. The aramid frame layer 4 adopts D3150 type aramid cord fabric, and the single layer strength is 3150N / mm; the buffer layer 6 adopts straight grain NN150 type canvas.

[0098] Flame-retardant adhesive layer compound formula, its proportion by weight:

[0099] 40 parts of natural rubber, styrene-butadiene rubber: 60 parts,

[0100] Zinc oxide: 5 parts, Magnesium oxide: 2 parts,

[0101] Stearic acid: 2 parts,

[0102] Accelerator CZ: 1.7 parts, Accelerator DM: 1.0 parts,

[0103] Flame retardant tackifying resin: 5 parts,

[0104] Tris (2,3-dibromopropyl) isocyanurate: 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com