Tensile fatigue and torsional fatigue testing machine for automobile parts

A technology for auto parts and torsional fatigue, which is applied in the field of tensile and torsional fatigue testing machines and fatigue testing machines, can solve the problems of poor versatility of equipment, complex structural connections, limited usability, etc., to reduce test costs, test accuracy, The effect of remarkable versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

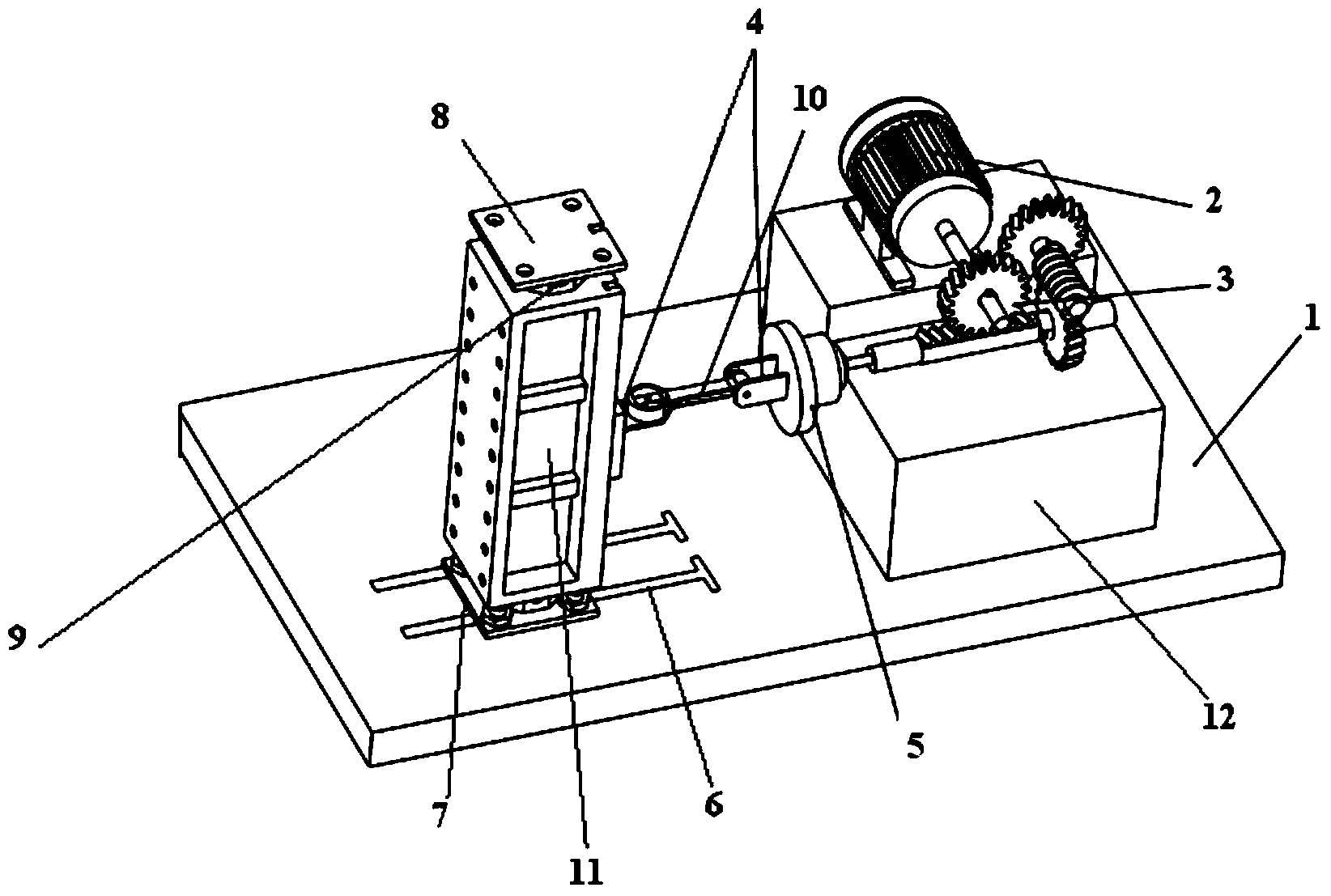

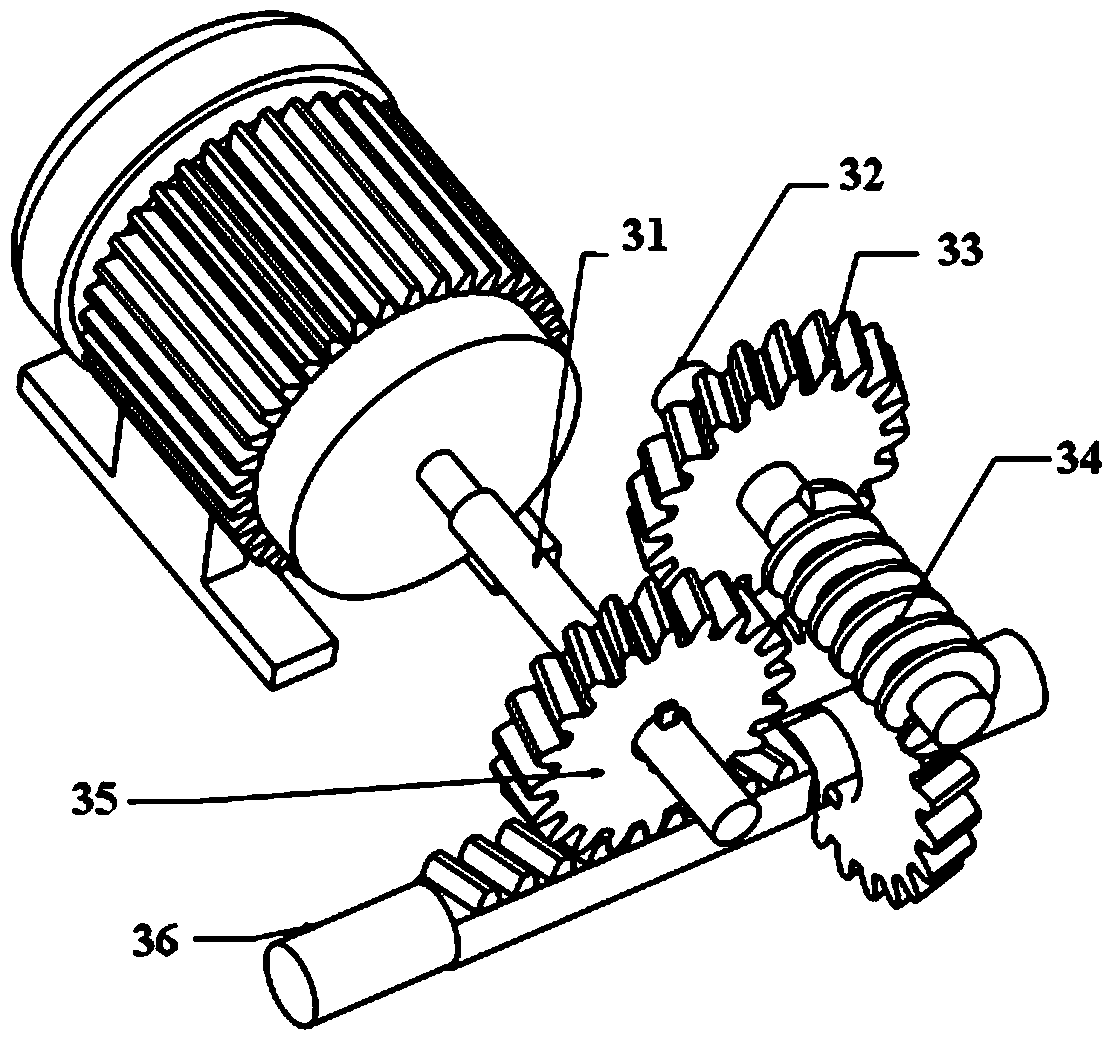

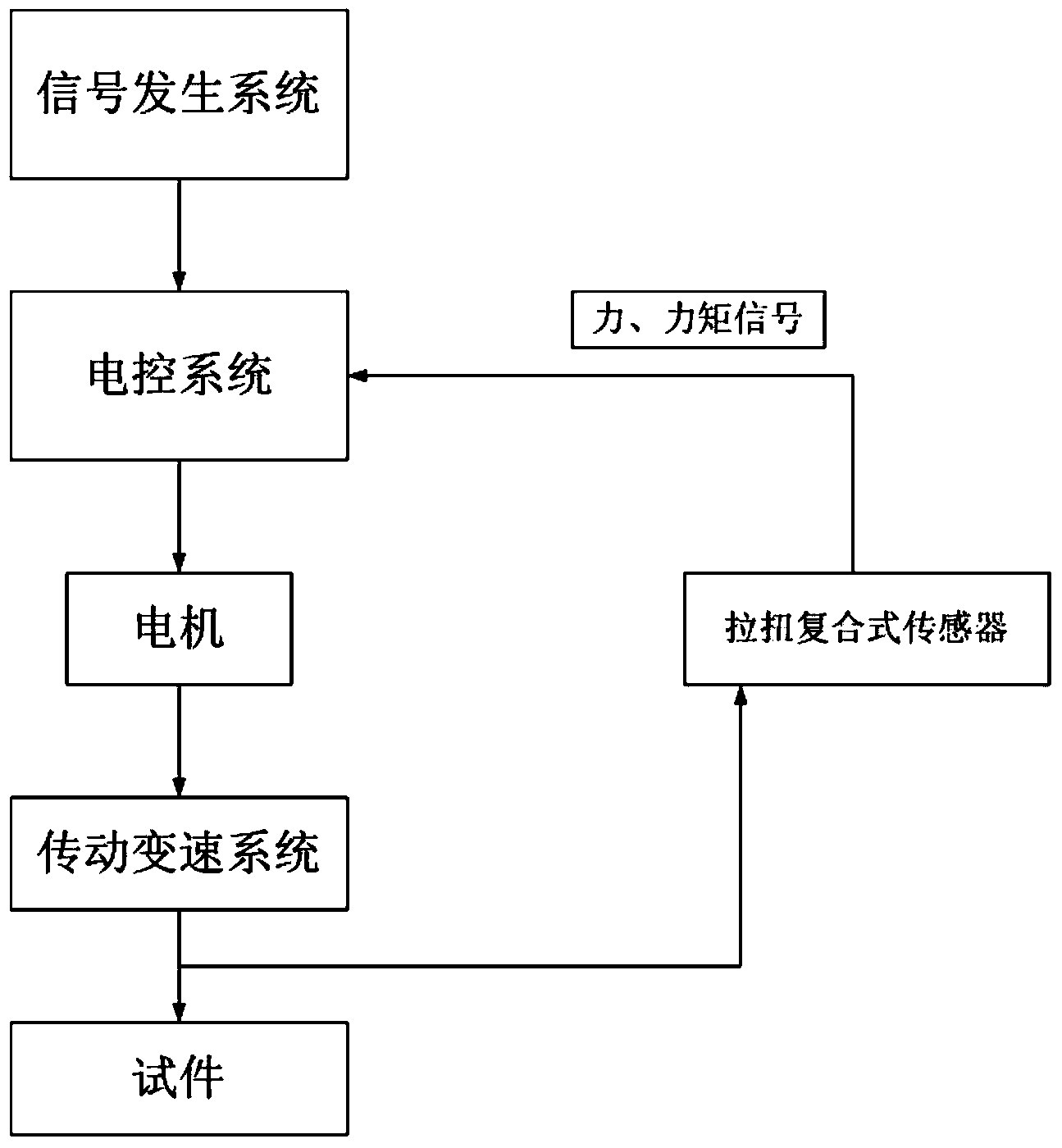

[0030] Such as Figure 1~2 As shown, a tensile and torsional fatigue testing machine for auto parts, the testing machine includes a support table 1, a motor 2, a test piece 10, a universal fixture 4, an installation column and a base 12, and the installation column and the base 12 are respectively They are oppositely arranged on the left and right sides of the support platform 1. The testing machine also includes an electric control system, a signal generation system, a tension-torsion compound sensor 5 and a transmission transmission system 3. The motor 2 and the transmission transmission system 3 are both arranged on the base. 12, the input end of the transmission variable speed system 3 is fixedly connected with the output shaft of the motor 2, and the output end is provided with a pull-twist composite sensor 5, and a pair of universal clamps 4 are arranged on the installation column and the pull-twist composite sensor 5 facing each other. Above, the test piece 10 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com