High-strength long-service-life rack steel

A long-life, rack steel technology, applied in the field of rack steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

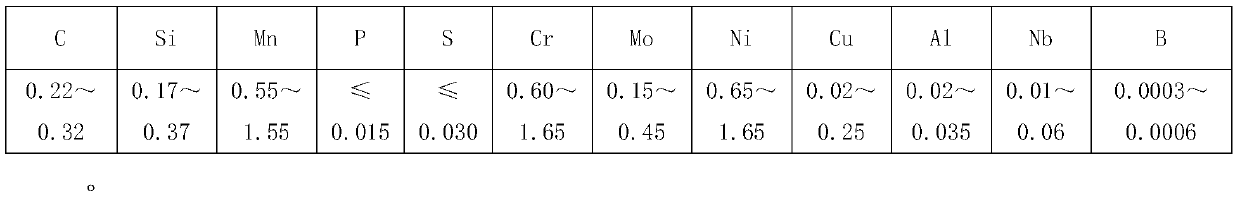

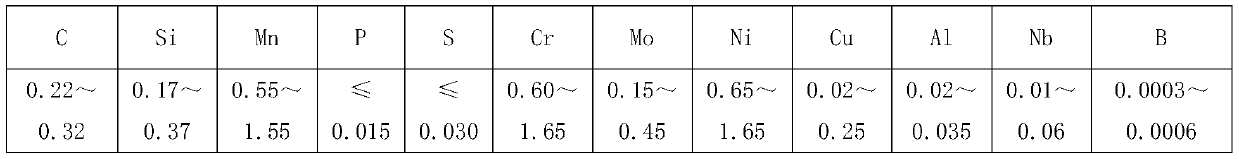

[0035]Melt 40 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.25%, Si: 0.26% , Mn: 0.85%, P≤0.008%, S≤0.006%, Cr: 1.35%, Mo: 0.21%, Al: 0.022%, Nb: 0.035%, Ni: 0.75%, Ti: 0.0004%, Cu: 0.12% , N: 0.0074%, O: 0.0009%, B: 0.0006%, and the balance is Fe and unavoidable impurity elements.

[0036] Heat the continuous casting slab to 1180-1240°C, keep it warm for more than 3 hours, start rolling at no lower than 1050°C, and roll it into a φ48mm round steel. The final rolling temperature is not lower than 950°C. After annealing and H expansion annealing, sample heat treatment and inspection.

[0037] ① Take φ20*200mm from 1 / 2 radius as the heat treatment blank;

[0038] ②Heat treatment method: quenching: heating to 890°C±10°C, holding for 45 minutes, oil quenching at room temperature; te...

Embodiment 2

[0041] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.26%, Si: 0.27% , Mn: 0.86%, P≤0.010%, S≤0.003%, Cr: 1.36%, Mo: 0.25%, Al: 0.020%, Nb: 0.033%, Ni: 0.80%, Ti: 0.0008%, Cu: 0.12% , N: 0.0068%, O: 0.0010%, B: 0.0005%, and the balance is Fe and unavoidable impurity elements.

[0042] Heat the continuous casting slab to 1150-1200°C, keep it warm for more than 3 hours, start rolling at 1080°C, finish rolling temperature ≥ 950°C, roll to φ48, H-expansion annealing within 15 hours after the steel is off-line, sample heat treatment after H-expansion annealing ,test.

[0043] ① Take φ20*200mm from 1 / 2 radius as the heat treatment blank;

[0044] ②Heat treatment: Quenching heating at 890°C±10°C, heat preservation for 45 minutes, oil quenching at room temperature; tempering hea...

Embodiment 3

[0047] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 300mm×340mm. The chemical composition of the obtained continuous casting slab includes: C: 0.26%, Si: 0.26% , Mn: 0.86%, P≤0.008%, S≤0.006%, Cr: 1.38%, Mo: 0.21%, Al: 0.022%, Nb: 0.033%, Ni: 1.15%, Ti: 0.0004%, Cu: 0.06% , N: 0.0078%, O: 0.0008%, B: 0.0005%, and the balance is Fe and unavoidable impurity elements.

[0048] Heat the continuous casting slab to 1150-1240°C, keep it warm for more than 4.5 hours, start rolling at 1050°C, finish rolling at a temperature not lower than 950°C, roll to φ48, air-cool after rolling, and H-expand and anneal within 15 hours after the steel is rolled off the production line. After H-expansion annealing, sample heat treatment and inspection.

[0049] ① Take φ20*200mm from 1 / 2 radius as the heat treatment blank;

[0050] ②Heat treatment: heating to 890°C±10°C, holding for 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatigue limit | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com