Test method and device thereof for reciprocating tensile fatigue testing of safety break-away valves for oiling machines

A technology of fatigue test and test method, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve problems such as potential quality hazards, safety accidents, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

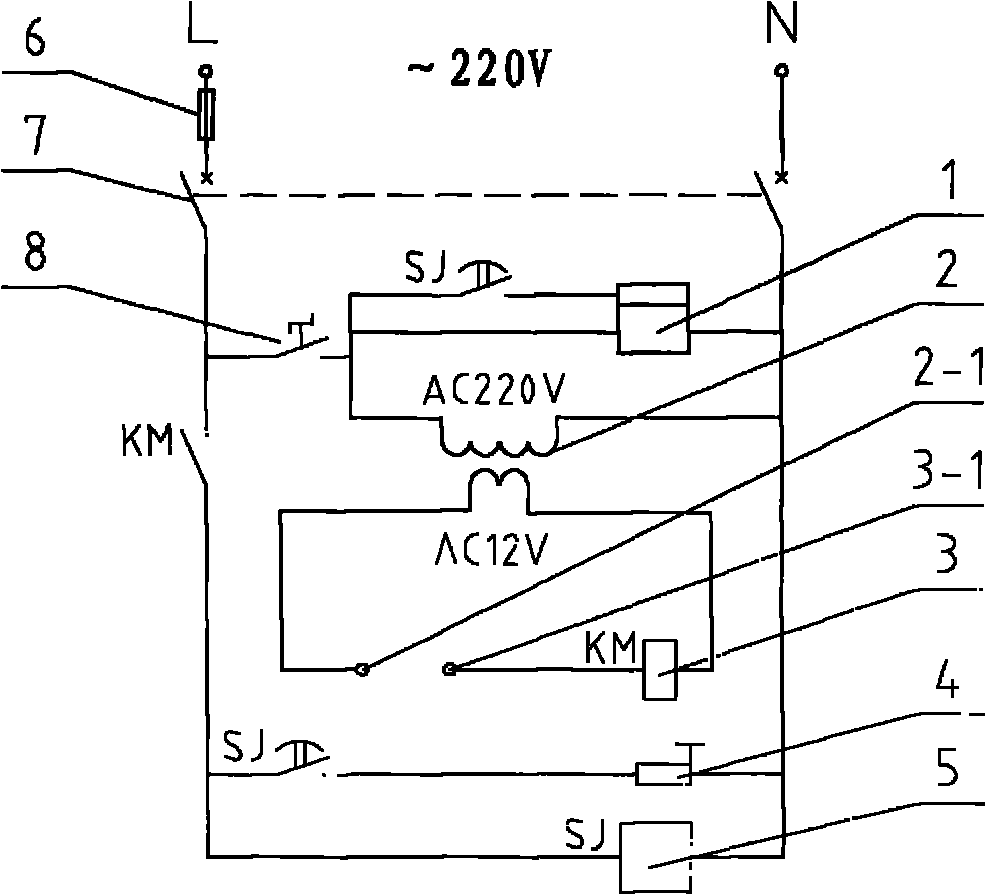

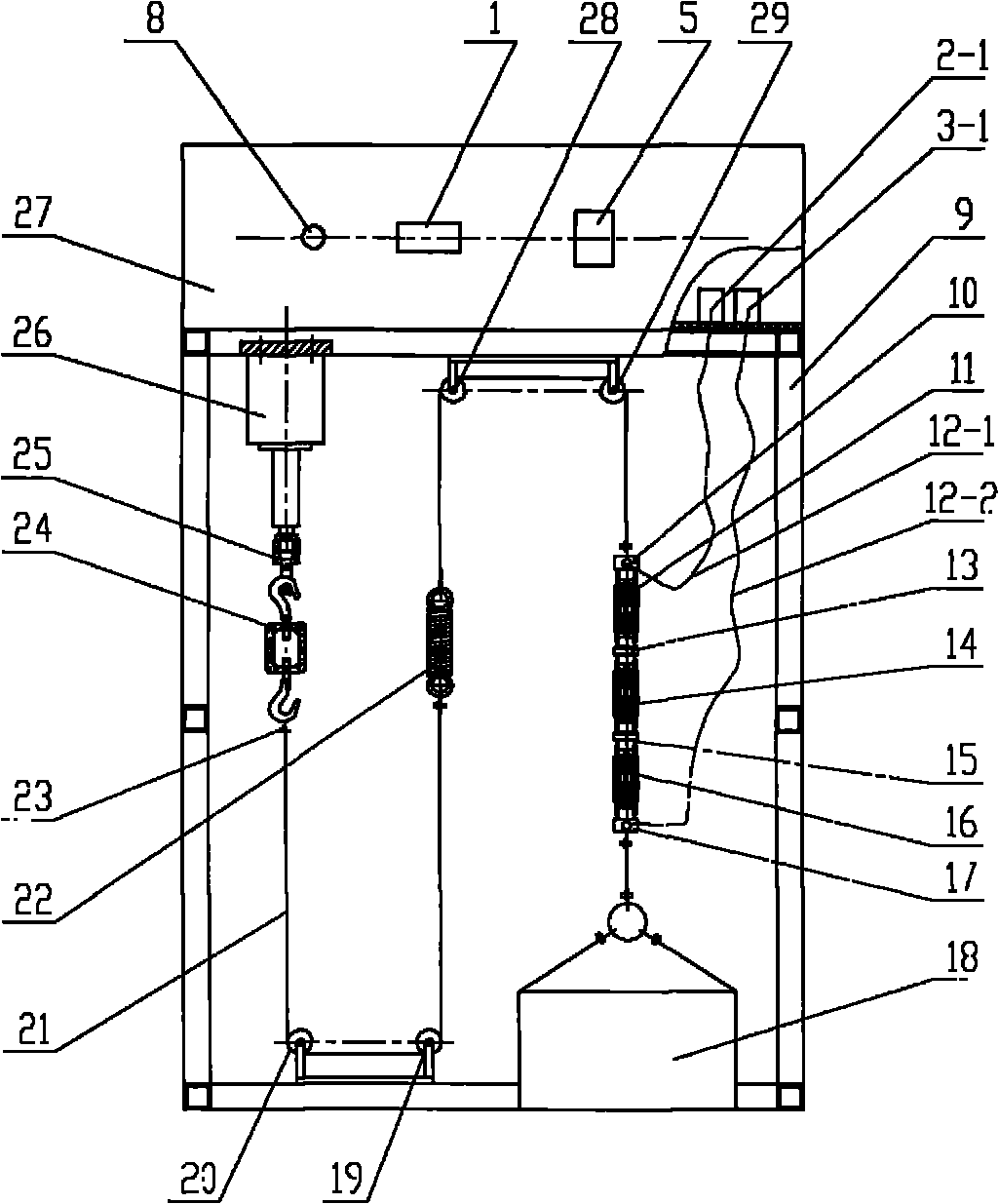

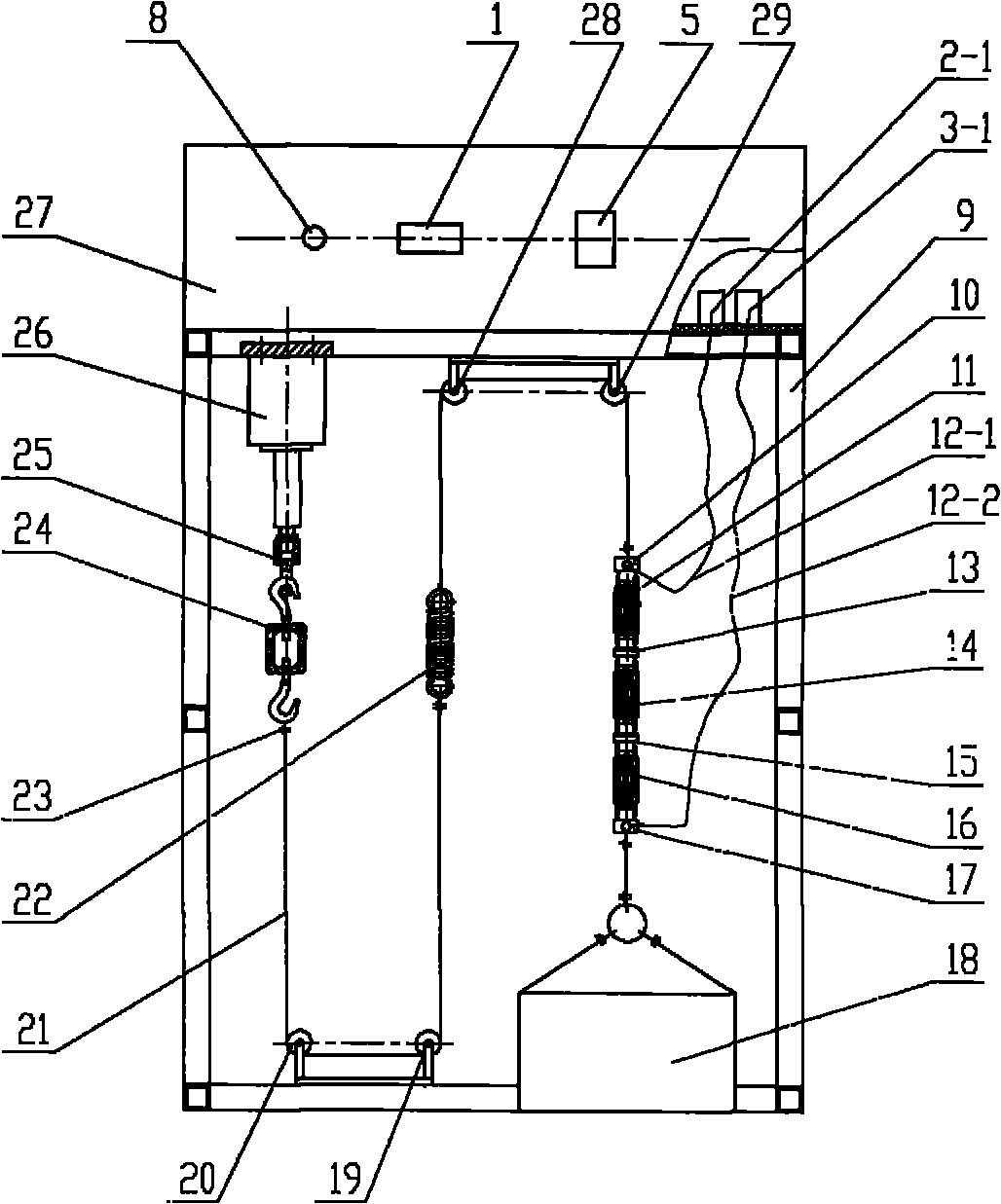

[0012] In the test method of the present invention, 3 safety breakaway valves of the same batch are randomly selected as test objects, A, B and C, placed in a test device, and connected in series with the moving components of the test device in an orderly manner. Form a control loop; set the pulling force required by the tested safety breaking valve as F, and the pulling force F should meet the condition of 0≤F≤A, and the pulling force borne by the tested safety breaking valve will be reduced by 3S-5S in time. F gradually increases from 0 Newton to A Newton, delays for 3S-5S, and then uses 3S-5S to gradually reduce the tension F on the tested safety breakaway valve from A Newton to 0 Newton, thus forming a reciprocating For the cycle of the tensile fatigue test, the number of synchronously displayed on the counter 1 is 1 time, and so on, when the repeated cycle reaches 10,000 times, and the tested safety breakaway valve does not break, then the batch of safety breakaway valves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com