Spring-lever energy storage type fatigue tension test machine

A technology of tensile testing machine and testing machine, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of expensive equipment and high cost of experiments, and achieve the goal of reducing impact, reducing vibration and impact, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

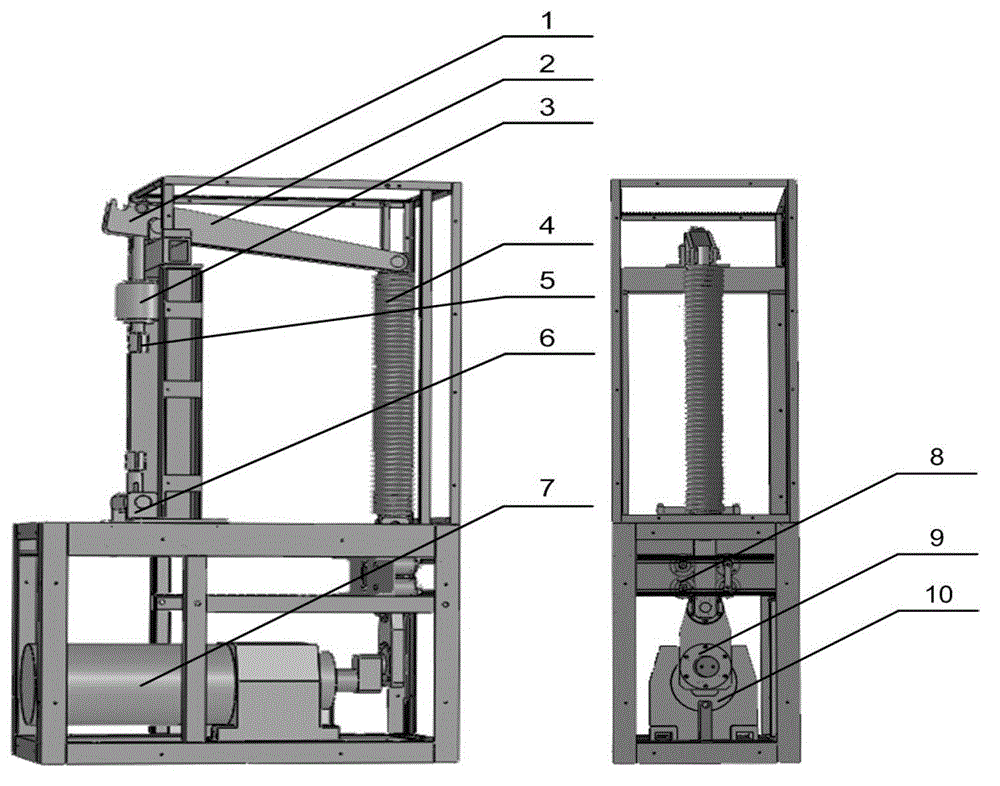

[0013] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

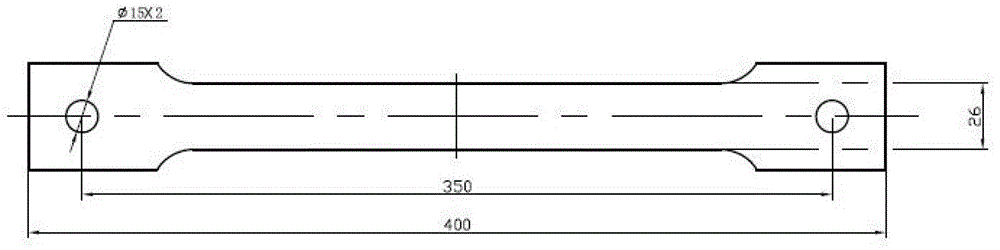

[0014] In the embodiment, the 16MnR material commonly used in the pressure vessel is used to make the tensile test piece. The effective width of the test piece is 26mm, and the thickness of the test piece is 4mm. The main structural dimensions of the test piece figure 2 shown.

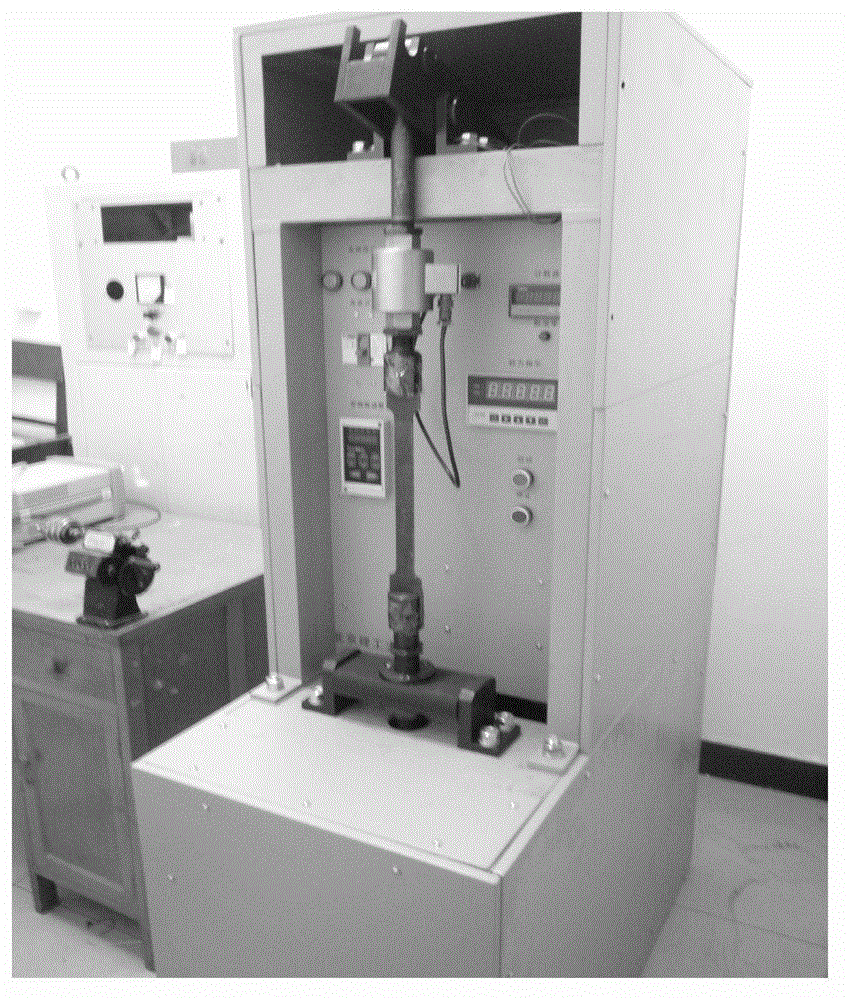

[0015] Implementation process: 1. First, pull out the fixing screws of the upper and lower stretching heads 5 and 6 of the stretching machine, and when the specimen is aligned with the upper and lower stretching heads, insert the fixing screws into it. At this time, the specimen has been fixed on the stretching machine. 2. Turn on the power switch, and the power indicator light will be on. 3. Set the pre-tightening force to 10000N by adjusting the base nut, and the pre-tightening force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com