Method for evaluating low-temperature performance and fatigue performance of crack filling adhesive for asphalt pavement

An evaluation method and technology of asphalt pavement, applied in the direction of strength characteristics, using repeated force/pulsation force to test material strength, measuring device, etc., can solve the problems of long time required, waste of manpower and material resources, etc., to ensure thickness and good application conditions and test data are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

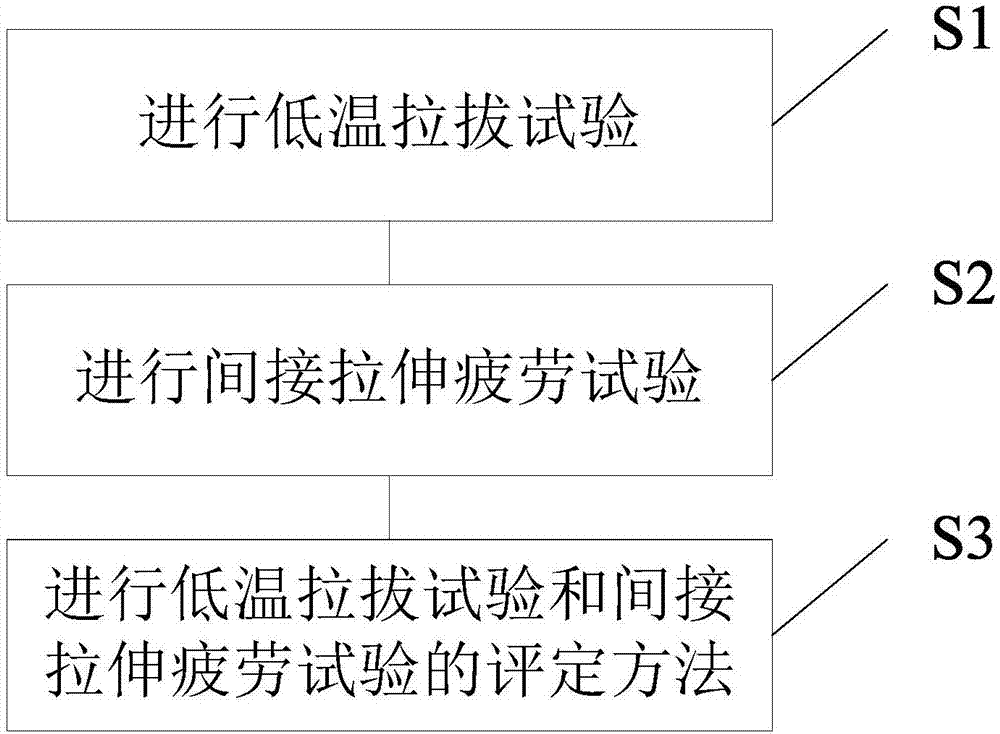

[0044] refer to figure 1 As shown, the embodiment of the present invention provides a method for evaluating the low temperature and fatigue performance of the joint glue for asphalt pavement, comprising the following steps:

[0045] Step S1 is to carry out the low temperature drawing test;

[0046] Step S2 carries out indirect tensile fatigue test;

[0047] Step S3 is to carry out the evaluation method of the low-temperature pull-out test and the indirect tensile fatigue test.

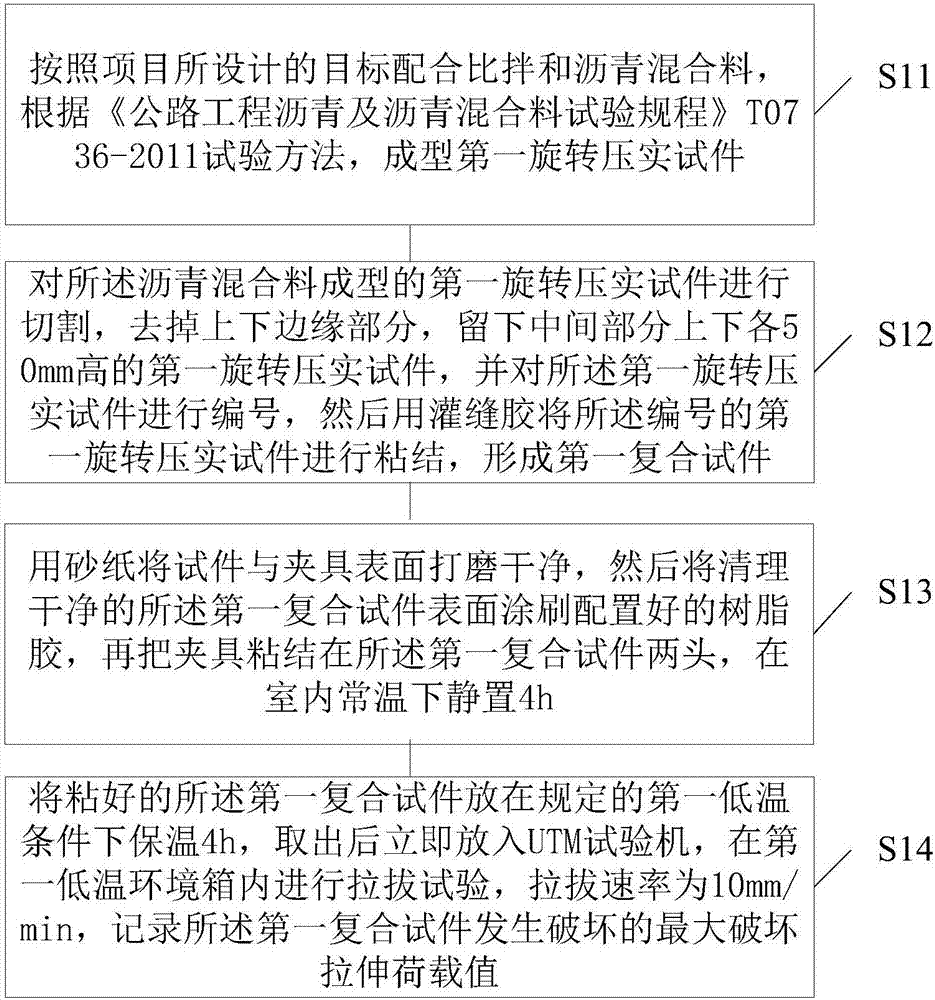

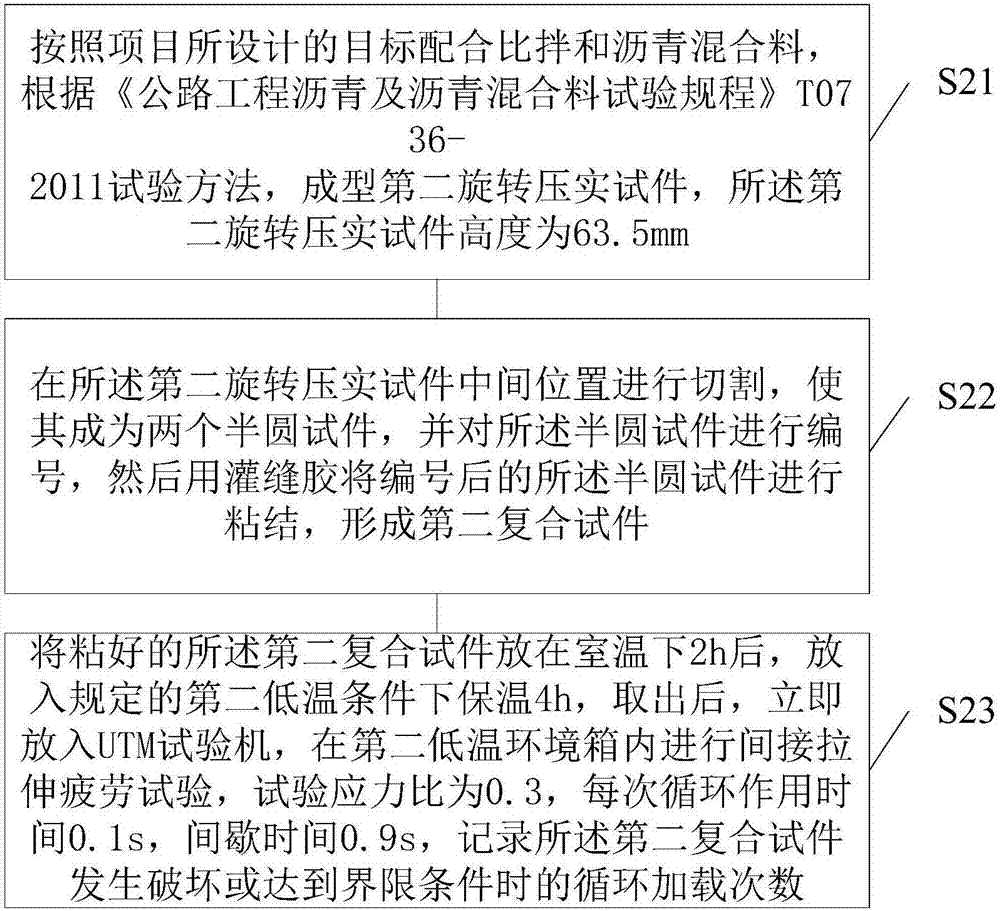

[0048] refer to figure 2As shown, wherein said step S1 to carry out the low temperature drawing test comprises the following steps:

[0049] Step S11 mixes the asphalt mixture according to the target mixing ratio designed by the project, and forms the first r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com