Composite material low temperature performance test fixture assembly

A low-temperature performance and composite material technology, applied in the direction of analysis materials, measurement devices, strength characteristics, etc., can solve problems such as sample slippage, and achieve the effect of guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

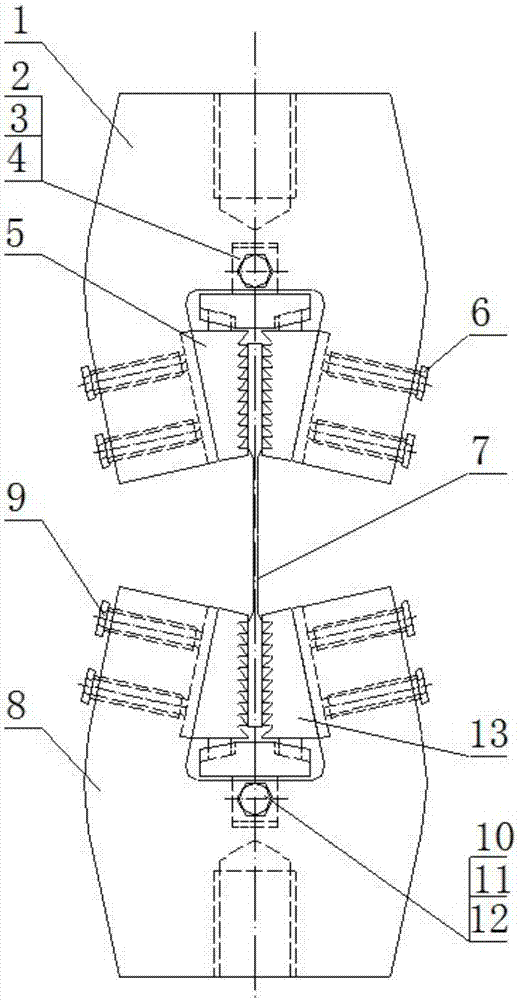

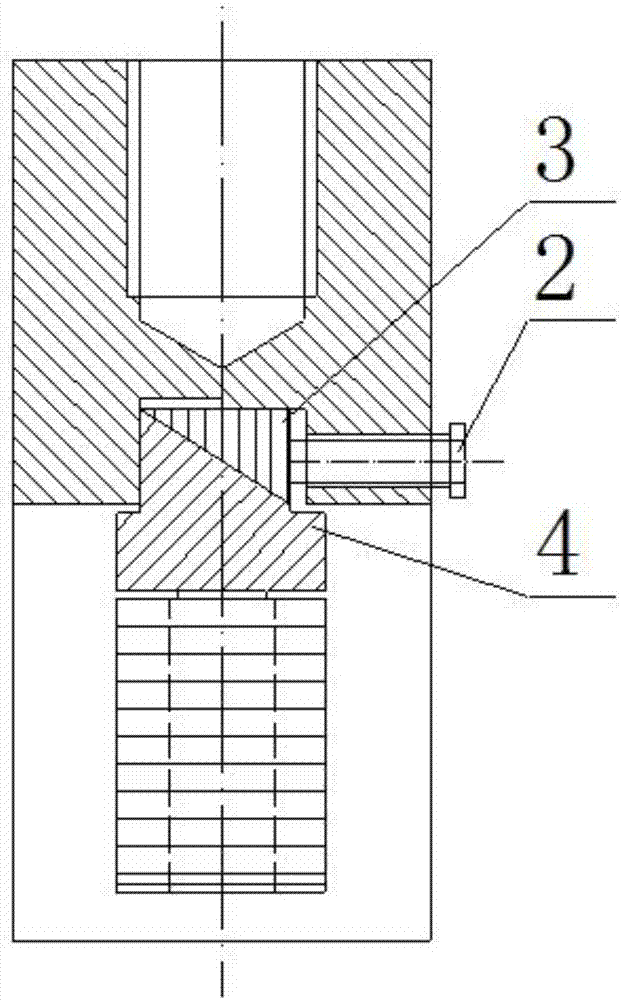

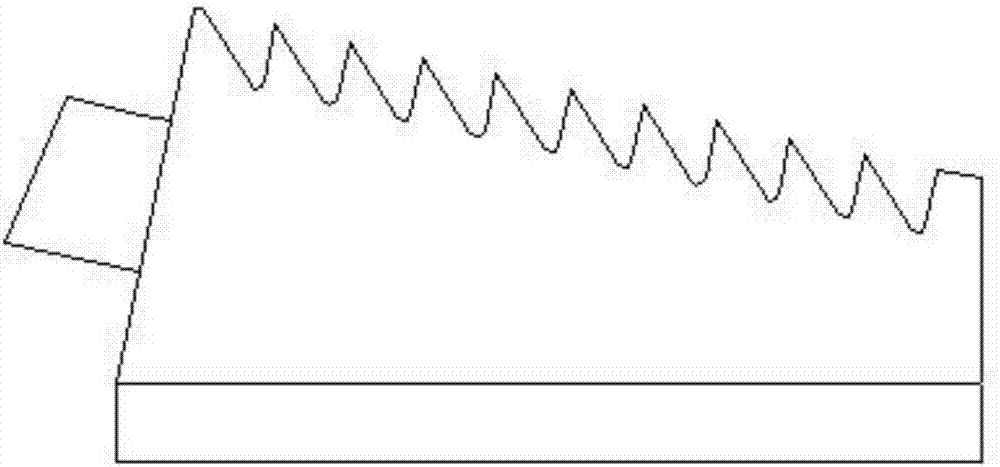

[0029] The fixture assembly used for the low-temperature performance test of composite materials includes two upper fixtures 1 and lower fixtures 8 for clamping the sample. The material of the two fixtures is Inconel718 alloy, or materials similar to Inconel718 in terms of mechanical properties. The structure, material and size of the upper fixture 1 and the lower fixture 2 are exactly the same, both including: clamping sliders 5, 13 for clamping the sample, driven sliders 4, 10 for driving vertical displacement, and Transition sliders 3, 11 that are displaced horizontally to the transmission, brake bolts 2, 12 used to generate braking force, and forced clamping bolts 6, 9 used to forcefully clamp the sample.

[0030] The following fixture 1 is taken as an example to describe in detail:

[0031] One end of the upper fixture 1 is provided with a screw s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com