High-temperature tensile-fatigue mechanical property tester and method based on electric cylinder drive

The technology of an electric cylinder and tester is applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/pressure, scientific instruments, etc., and can solve the problems of limited use, measurement errors of test pieces, Complex structure and other problems, to achieve the effect of fewer transmission links, simple structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

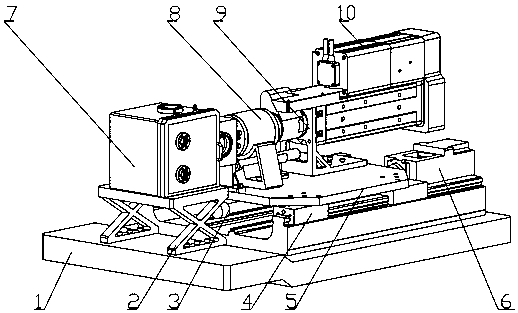

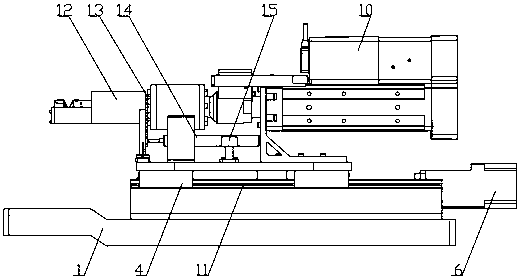

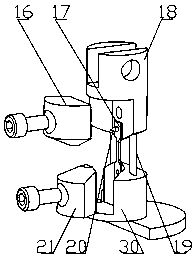

[0029] see Figure 1 to Figure 5 As shown, the electric cylinder-driven high-temperature tensile-fatigue mechanical property tester of the present invention adopts a horizontal layout as a whole, including a mechanical property test module, a high-temperature loading module and a mobile platform, and the mechanical property test module is placed on the mobile platform On, the mobile platform realizes the axial movement of the mechanical performance testing module; the double-chamber high-temperature heating furnace 7 of the high-temperature loading module is placed on one side of the mechanical performance testing module; after the double-chamber high-temperature heating furnace reaches the set temperature, it moves The clamp body unit with the dynamic performance test module on the platform enters the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com