Biaxial tensile fatigue test piece with conic curve transition and test method thereof

A conic curve and biaxial stretching technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problem that the uniaxial stretching test method cannot faithfully reflect the stress of the material, and achieve in-situ Biaxial stretching, easy and accurate positioning, and accurate data effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

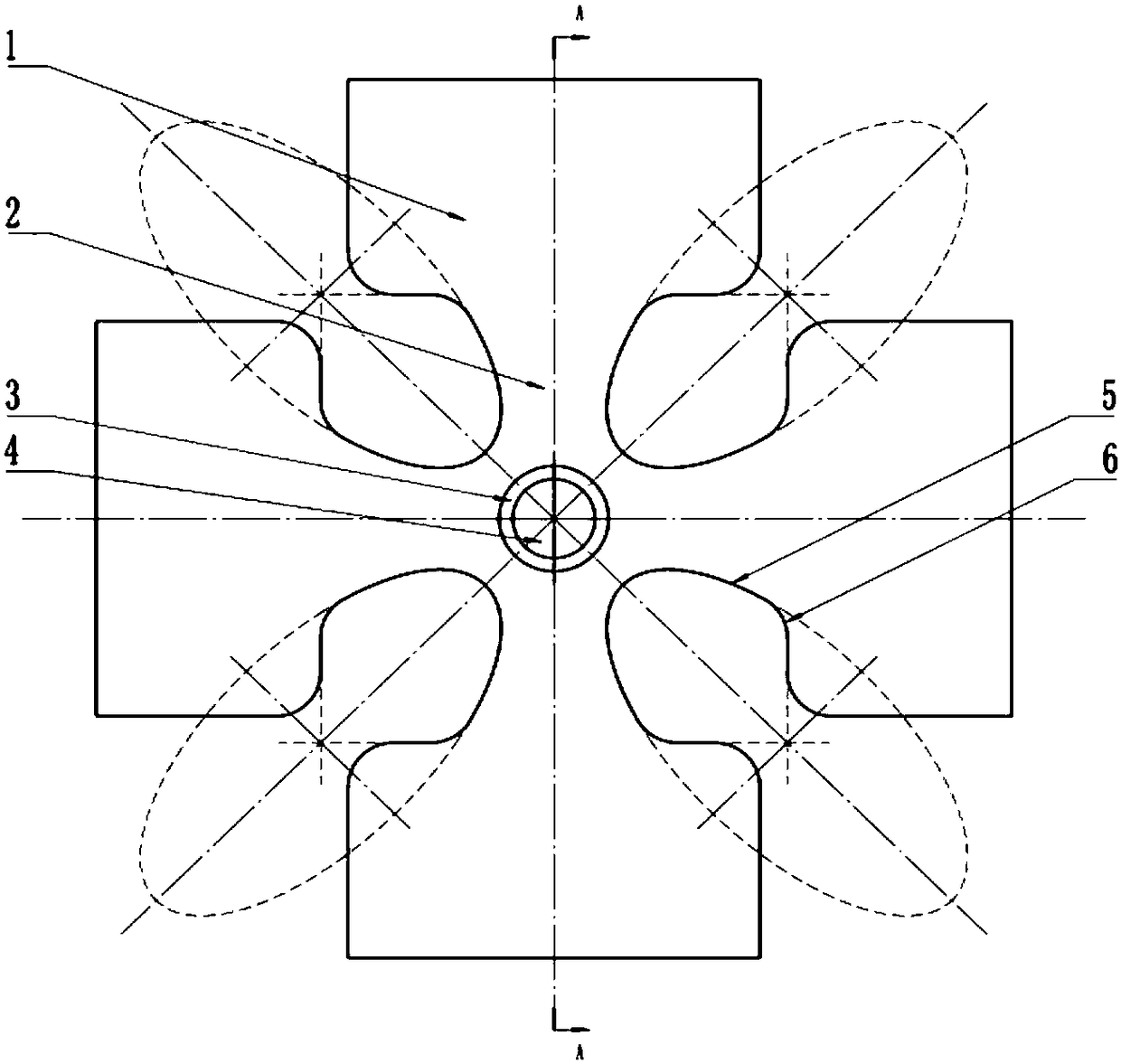

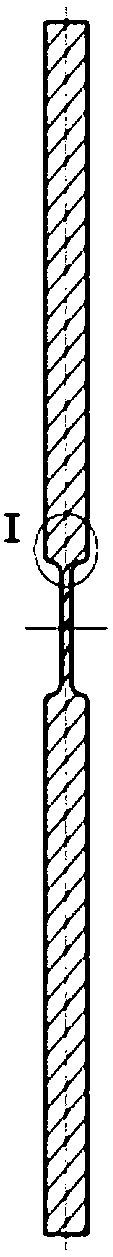

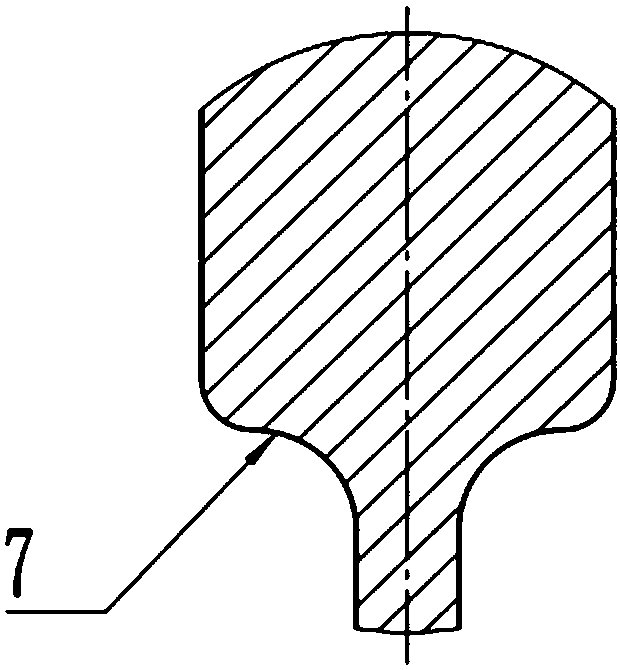

[0029] Such as Figure 1a As shown, a biaxial tensile fatigue test piece with a conic curve transition, the test piece is in the shape of a cross as a whole, with four loading arms, one end of the four loading arms converges into a central area 4, and the other end is a clamping area 1 , the test piece is clamped by means of clamps, etc., and a transition zone 2 formed by a conic curve 5 is provided between the roots of adjacent loading arms. The conic curve 5 is an ellipse, and the major axis of the ellipse coincides with a symmetrical axis of the test piece. The transition between the conic curve 5 and the clamping area 1 is a rounded part 6; the thickness of the clamping area 1 is thicker than that of the central area 4, and there is a thickness reduction area 3 between the transition area 2 and the central area 4; the thickness reduction area 3 Used to connect the thicker transition zone 2 and the thinner central zone 4, the cross-sectional view along the A-A direction is a...

Embodiment 2

[0036] The basic structure of the test piece is the same as that of Example 1, except that the transition mode of the thickness reduction zone 3 in the thickness direction is changed to a spline curve 8, such as figure 2 As shown, where the spline curve 8 satisfies a smooth transition at the connection between the central area 4 and the transition area 2 .

Embodiment 3

[0038] The basic structure of the test piece is the same as that of Example 1, except that the transition mode of the thickness reduction zone 3 in the thickness direction is changed to a single arc 9, such as image 3 As shown, the single circular arc 9 satisfies a smooth transition at the connecting central area 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com