Experimental device used for evaluation of water stability of bituminous mixture and experimental method

A technology of asphalt mixture and water stability, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and using repeated force/pulsation force to test material strength, etc., which can solve the problem of water environment. Problems such as the difference in the use state of asphalt mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

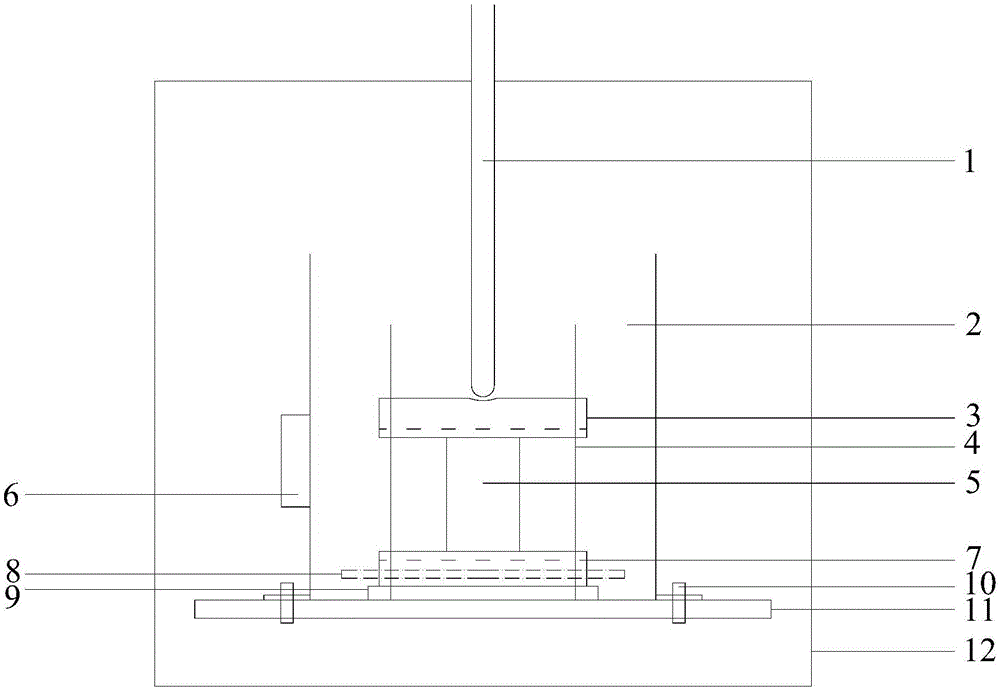

[0036] Example 1: Indirect Tensile Test Evaluation of Water Stability

[0037] Using the above experimental device, the indirect tensile test was used to evaluate the water stability of asphalt mixture under multi-field coupling, including the following steps:

[0038] Step 1: According to the designed gradation and the amount of asphalt, use a gyratory compactor or a Marshall compactor to form a cylindrical asphalt mixture specimen 5 with a height of 100mm and a diameter of 63.5mm, and measure the height h and diameter d of the specimen , calculate the cross-sectional area A of the test piece, and keep it at room temperature for 24 hours for later use.

[0039] Step 2: The bottom of the working box 2 is provided with screw holes, the spacing of which is the same as that of the fixed screw holes on the workbench 11, and the fixing device 10 is used to closely connect the workbox 2 and the workbench 11.

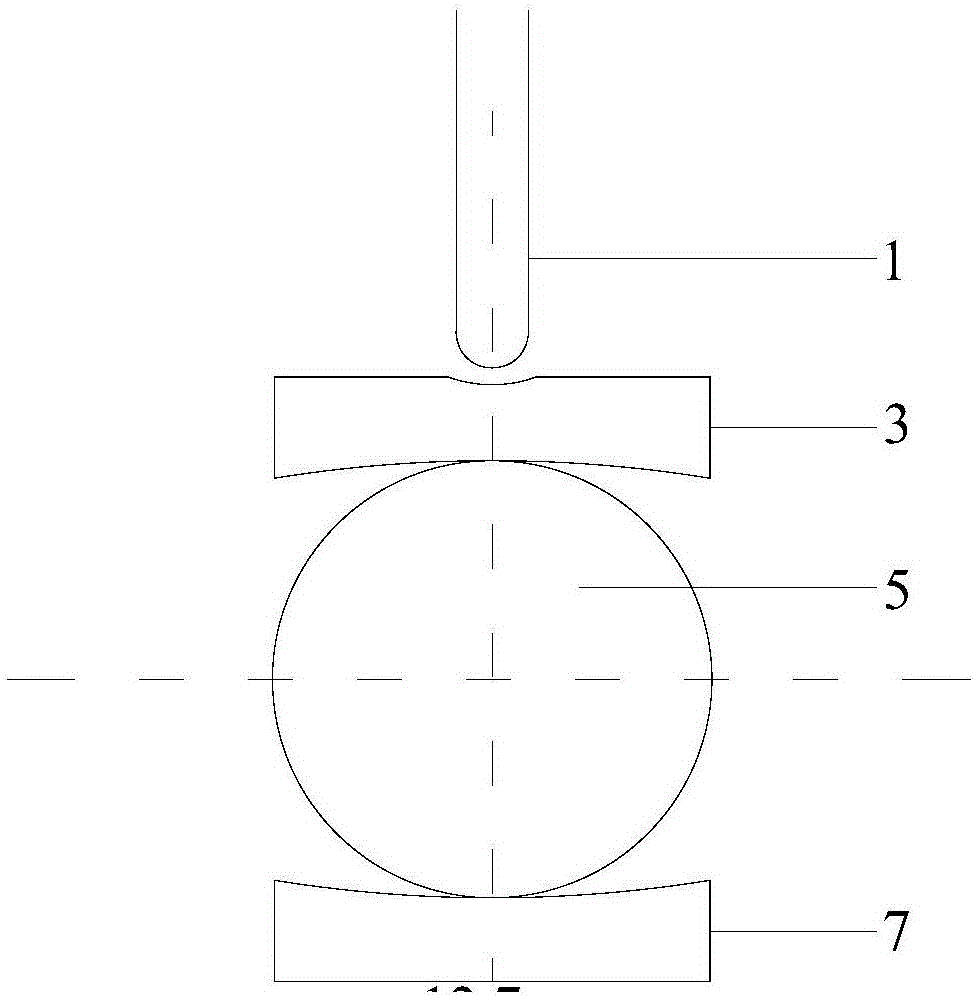

[0040] Step 3: The lower bead 7 of the indirect tensile test device is f...

Embodiment 2

[0046] Example 2: Indirect Tensile Fatigue Test Evaluation of Water Stability

[0047] Step 1: Form the same cylindrical asphalt mixture specimen 5 as in Example 1, measure the height h and diameter d of the specimen, calculate the cross-sectional area A of the specimen, and keep it at room temperature for 24 hours before use.

[0048] Step 2: The bottom of the working box 2 is provided with screw holes, the spacing of which is the same as that of the fixed screw holes on the workbench 11, and the fixing device 10 is used to closely connect the workbox 2 and the workbench 11.

[0049] Step 3: The lower bead 7 of the indirect tensile test device is fixed on the fixture 9, the fixture 9 and the column 4 are tightly connected to the bottom of the working box 2 through the screw holes, the upper bead 3 is fixed on the two columns 4, and can slide up and down freely. The upper bead and the lower bead are arranged in parallel and opposite to each other.

[0050] Step 4: Slowly inje...

Embodiment 3

[0055] Embodiment 3: Water stability performance evaluation under dynamic temperature field

[0056] Step 1: Form the same cylindrical asphalt mixture specimen 5 as in Example 1, measure the height h and diameter d of the specimen, calculate the cross-sectional area A of the specimen, and keep it at room temperature for 24 hours before use.

[0057] Step 2: The bottom of the working box 2 is provided with screw holes, the spacing of which is the same as that of the fixed screw holes on the workbench 11, and the fixing device 10 is used to closely connect the workbox 2 and the workbench 11.

[0058] Step 3: The lower bead 7 of the indirect tensile test device is fixed on the fixture 9, the fixture 9 and the column 4 are tightly connected to the bottom of the working box 2 through the screw holes, the upper bead 3 is fixed on the two columns 4, and can slide up and down freely. The upper bead and the lower bead are arranged in parallel and opposite to each other.

[0059] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com