Index screening and processing method for evaluating quality of tobacco leaves

A technology of quality indicators and processing methods, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of only focusing on individual indicators of tobacco leaf quality, no comprehensive evaluation of multiple indicators, information redundancy, etc., and achieve cigarette raw materials. The evaluation results are scientific, instructive and practical, and the data is easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The samples were collected from the primary flue-cured tobacco leaf samples of four base units in the three cigarette industrial production areas of Chuxiong, Dali and Lijiang in Yunnan Province, which mainly produce flue-cured tobacco. The variety is the largest main planted variety in the township. Select 35 representative samples of C3F grade in the industrial and commercial handover samples, and the sampling volume of each sample is 3kg.

[0041] 1. Analyze the collected data

[0042] (1) Quantitative evaluation of the appearance quality of the tobacco leaves in the cigarette raw material base

[0043] Appearance quality indicators include: color, maturity, leaf structure, identity, oil content, and chroma. The quantitative evaluation method is based on the GB2635-92 flue-cured tobacco grading standard to determine the scoring standard for appearance quality (Table 1). The flue-cured tobacco leaf grading technicians judge and score the individual appearance quality...

Embodiment 2

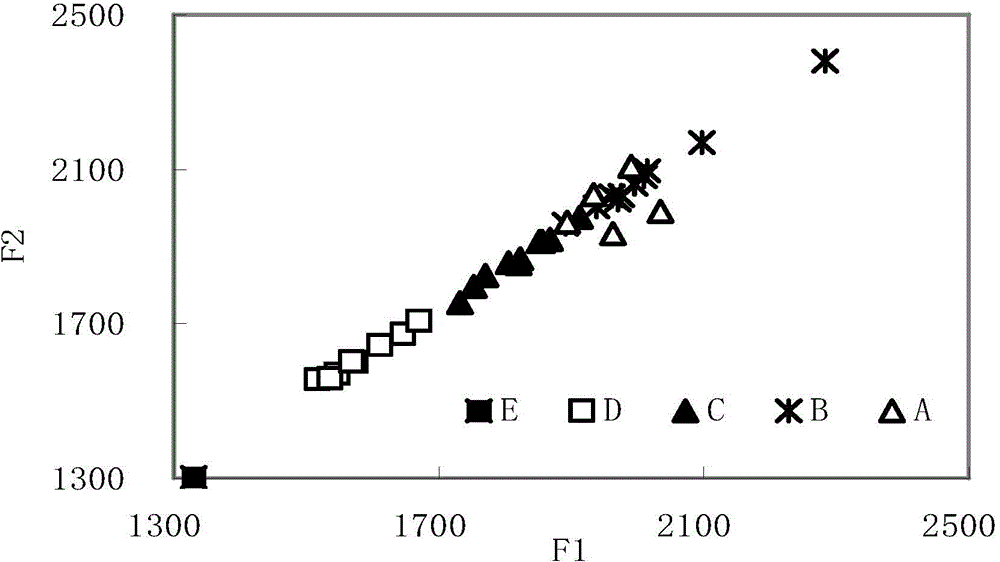

[0097] (1) Obtain 3 samples of tobacco leaves to be evaluated from 4 base units in 3 production areas of Yunnan Chuxiong, Dali and Lijiang of Jiangsu China Tobacco Industry Co., Ltd., and determine the scoring standard for appearance quality according to the GB2635-92 flue-cured tobacco grading standard (Table 1) . Each individual appearance quality index of the sample is judged and scored item by item. Use the methods specified in YC / T159-2002, YC / T160-2002, YC / T161-2002, YC / T162-2002, YC / T173-2003 to determine the total sugar and reducing sugar, nicotine, and total nitrogen in tobacco leaf samples. , chlorine, potassium. The measured chemical composition content was converted into percentage. The sugar-base ratio refers to the ratio of the total sugar content to the nicotine content, and the potassium-chloride ratio refers to the ratio of the potassium content to the chlorine content. Refer to the standard YC / T138-1998 to establish the evaluation criteria for the sensory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com