Radar-infrared combined stealth material and preparation method thereof

A stealth material, infrared technology, applied in the direction of chemical instruments and methods, laminated, layered products, etc., can solve the problems of stealth function effect to be strengthened, cumbersome process, complex structure, etc., to achieve easy scale production and application, process Simple and effective in improving the absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

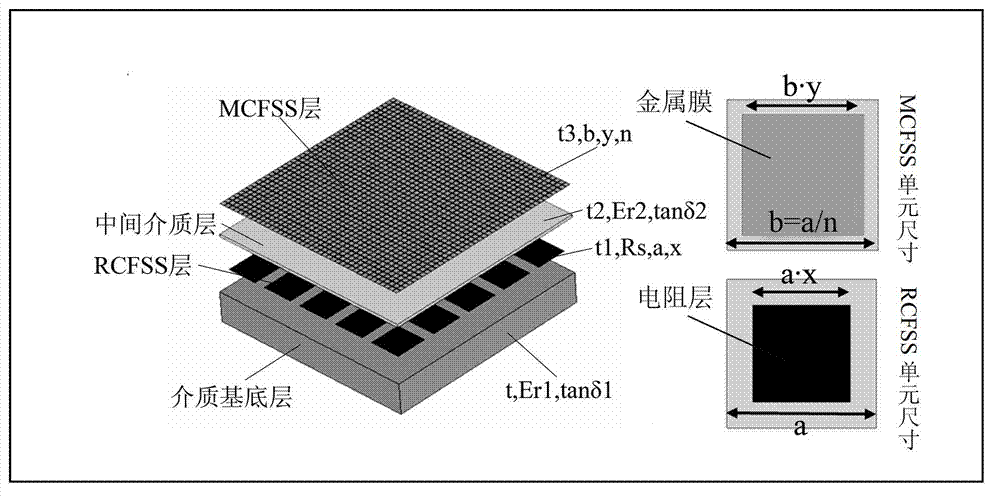

[0032] A radar and infrared compatible stealth material of the present invention, such as figure 1 As shown, the compatible stealth material includes metal capacitive frequency selective surface layer (MCFSS layer), intermediate dielectric layer (FR-4 dielectric plate), resistive capacitive frequency selective surface layer (RCFSS layer) and Dielectric base layer (epoxy resin glass steel plate), its specific structural parameter values are shown in Table 2 below:

[0033] Table 2 The value of each structural parameter of the radar and infrared compatible stealth material of embodiment 1

[0034]

[0035] A preparation method of the radar and infrared compatible stealth material of the present embodiment, comprising the following steps:

[0036] (1) Buy FR-4 single-sided copper clad laminates directly in the market;

[0037] (2) Using PCB technology to corrode the FR-4 single-sided copper clad board as figure 1 The metal-type capacitive frequency selective surface layer...

Embodiment 2

[0044] A radar and infrared compatible stealth material of the present invention, such as figure 1 As shown, the compatible stealth material includes metal capacitive frequency selective surface layer (MCFSS layer), intermediate dielectric layer (FR-4 dielectric plate), resistive capacitive frequency selective surface layer (RCFSS layer) and Dielectric base layer (unsaturated polyester resin glass steel plate), its specific structural parameter values are shown in Table 4:

[0045] Table 4 The value of each structural parameter of the radar and infrared compatible stealth material of embodiment 2

[0046]

[0047] A preparation method of the radar and infrared compatible stealth material of the present embodiment, comprising the following steps:

[0048] (1) A layer of silver paste is printed on the FR-4 dielectric board by screen printing technology, and then cured to obtain a FR-4 single-sided silver-clad board;

[0049] (2) Use the circuit board engraving process to ...

Embodiment 3

[0056] A radar and infrared compatible stealth material of the present invention, such as figure 1 As shown, the compatible stealth material includes metal capacitive frequency selective surface layer (MCFSS layer), intermediate dielectric layer (FR-4 dielectric plate), resistive capacitive frequency selective surface layer (RCFSS layer) and Dielectric base layer (epoxy glass steel plate), its specific structural parameter values are shown in Table 6:

[0057] Table 6 The value of each structural parameter of the radar and infrared compatible stealth material of embodiment 3

[0058]

[0059] A preparation method of the radar and infrared compatible stealth material of the present embodiment, comprising the following steps:

[0060] (1) A layer of gold film is sputtered on the FR-4 dielectric board by magnetron sputtering process to obtain the FR-4 single-sided gold-clad board;

[0061] (2) Use the circuit board engraving process to engrave such as figure 1 The metal-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com