On-line monitoring system for capacitive equipment dielectric loss angle

A medium loss angle and monitoring system technology, applied in the field of monitoring systems, can solve problems such as long signal transmission distance, bottlenecks in off-site signal acquisition and transmission, inconvenient maintenance and expansion, and reduce the difficulty of construction and system installation costs. Scalability and the effect of flexibility, improved reliability and operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Referring to the above-mentioned accompanying drawings, specific embodiments of the present invention will be described in detail.

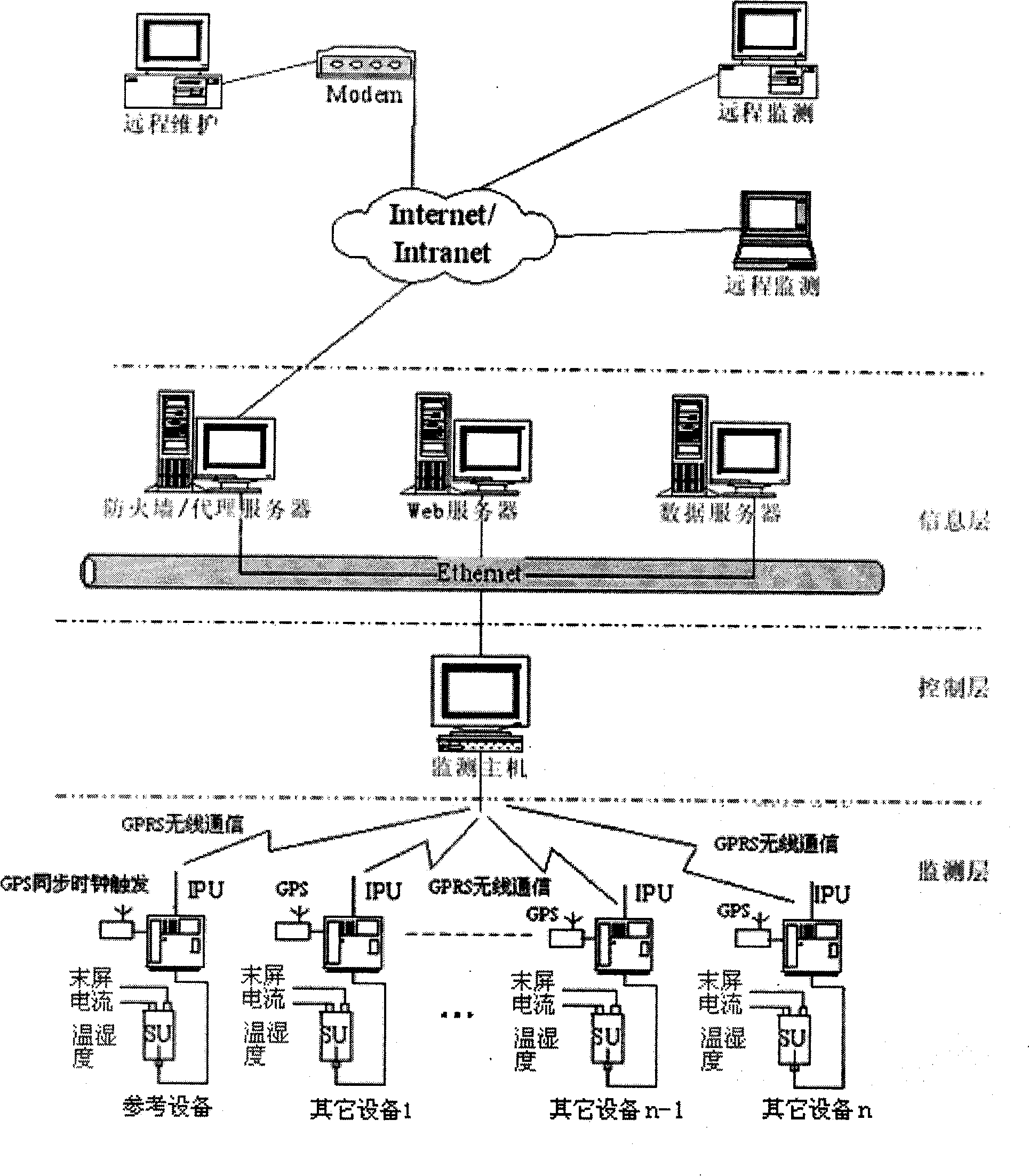

[0047] Such as figure 1 As shown, the whole system is composed of monitoring layer, control layer and information layer. The monitoring layer is mainly realized by the monitoring extension, including two parts: the signal acquisition unit (SU) and the intelligent processing unit (IPU). The SU completes the on-site extraction of the detection signal, and the IPU is mainly composed of the data central processing unit and the A / D sampling module. , GPS module, GPRS wireless communication module and power supply module, among which GPRS can complete the wireless communication with the control layer; the entity of the control layer is the monitoring host, which controls the on-site sampling unit through the GPRS network, reads the data, and then passes the Ethernet The network uploads data to the information layer; the information layer adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com