Electric heating tube made of hexagonal boron nitride and mixed heat conducting material thereof

A technology of hexagonal boron nitride and thermally conductive material, applied in the field of electric heating pipes, can solve the problems of incomplete discharge of moisture and air, oxidation resistance wire and metal inner wall, sealing leakage at both ends of electric heating pipes, etc., and achieves small gaps and regular particle shapes. , The effect of strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

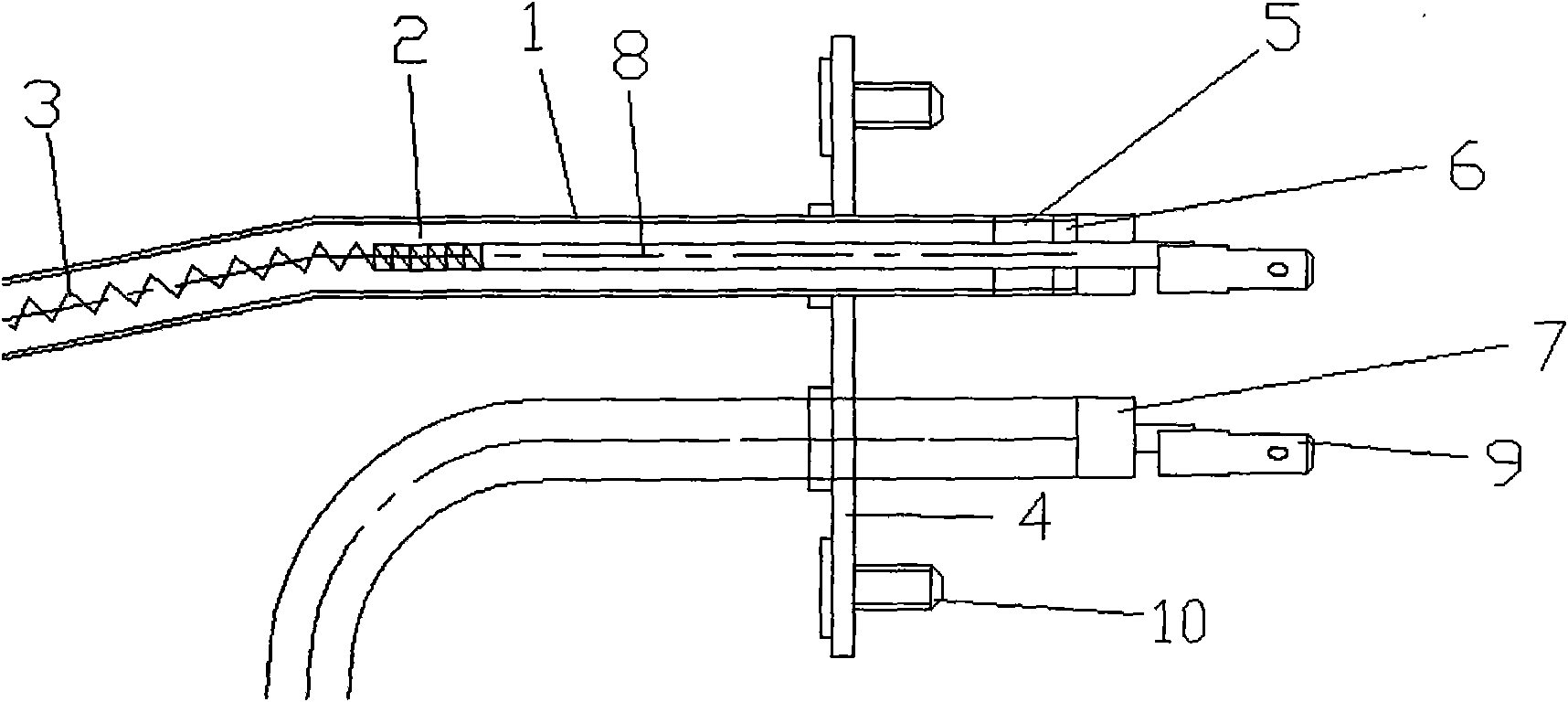

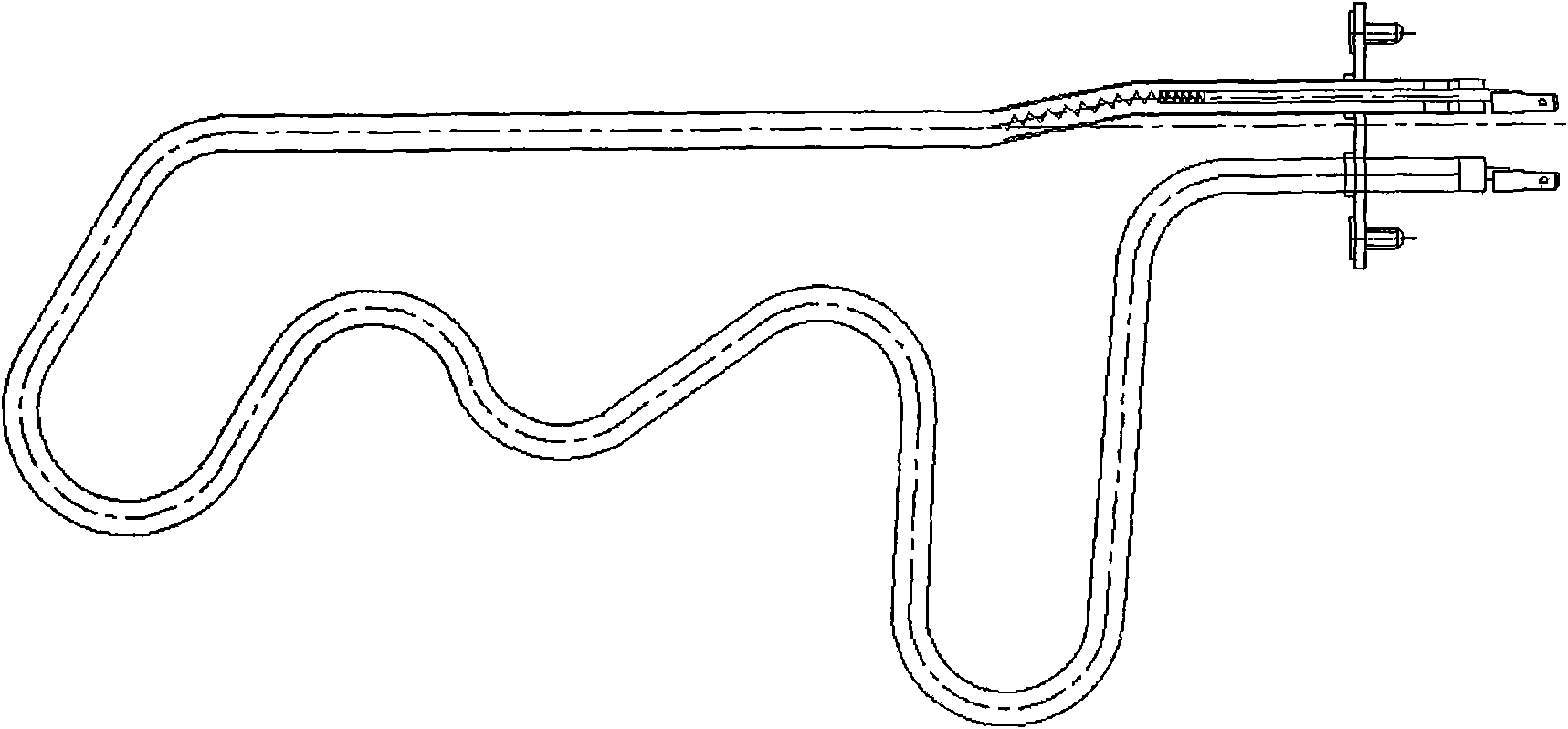

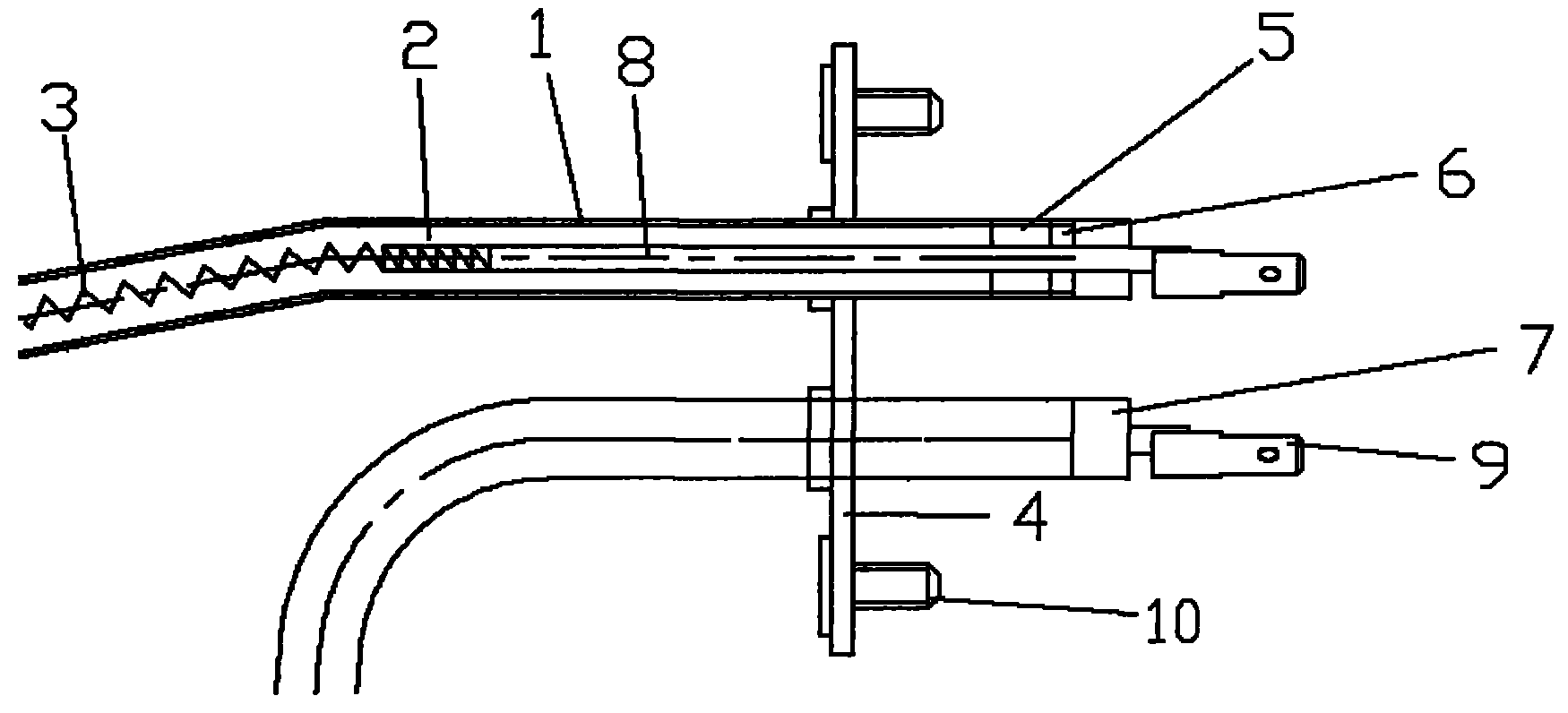

[0010] In this embodiment, hexagonal boron nitride or its mixture with magnesium oxide powder is used as the heat conduction material of the electric heating tube to prepare the electric heating tube; its main structure includes a metal tube body 1, a mixed filler 2, a resistance wire 3, a fixed piece 4, and ceramic beads 5. Sealant 6, plastic plug 7, lead-out rod 8, terminal electrode 9 and screw 10, metal tube body 1 inner cavity structure is bent into a circular, elliptical or spiral geometric structure, metal tube body 1 The parallel structure of the two ends is spaced and fixed on the fixed plate 4, and the two ends of the fixed plate 4 are fixed with screws 10; Resistance wire 3, the space between the resistance wire 3 and the wall of the metal pipe body 1 is filled and compacted with the mixed filler 2; the two ends of the metal pipe body 1 are connected with external terminal electrodes 9, and the metal pipe body 1 of the terminal electrodes 9 is sequentially manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com