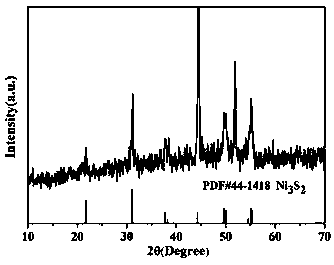

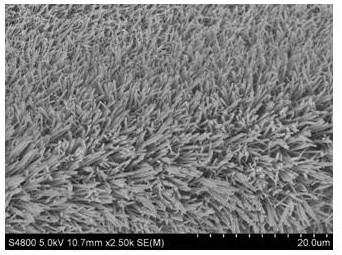

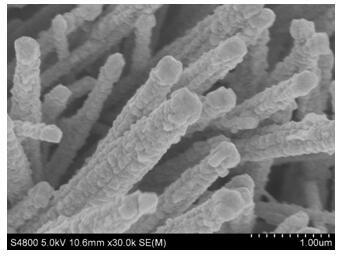

Vanadium-modified Ni3S2 nano-rod array electrode material and preparation method thereof

A nanorod array, electrode material technology, applied in electrodes, chemical instruments and methods, electrolysis process, etc., can solve the problems of harsh reaction conditions, large material overpotential, poor catalytic activity, etc., and achieves short reaction period and simple preparation process. , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Soak nickel foam (1×5) cm in acetone for 5 minutes, then immerse nickel foam in 1 mol / L hydrochloric acid for 5 minutes, and finally use ethanol and deionized water alternately Rinse 3 times and vacuum dry at 20 °C for 5 h to obtain the treated nickel foam;

[0033] (2) Weigh vanadyl acetylacetonate and thiourea, take vanadyl acetylacetonate as 0.04 mmol, control the molar ratio of vanadium source and sulfur source to 1:1, add it to 20 ml ethylenediamine at the same time, and magnetically Stir for 3 min to obtain suspension A;

[0034] (3) Add 0.001 g of ammonium fluoride to suspension A and stir for 1 hour to obtain solution B;

[0035] (4) Put the stirred solution B and the metal nickel treated in step (1) into a high-pressure reactor, and then place it in an oven for reaction, and perform a solvothermal reaction at 50°C for a reaction time of 0.5 h ;

[0036] (5) After the reaction was completed, the reactor was cooled at room temperature, and the product was ...

Embodiment 2

[0039] (1) Soak nickel foam (1×5) cm in acetone for 5 minutes, then immerse nickel foam in 1 mol / L hydrochloric acid for 5 minutes, and finally use ethanol and deionized water alternately Rinse 3 times and vacuum dry at 30 °C for 8 h to obtain the treated nickel foam;

[0040] (2) Weigh sodium metavanadate and thioacetamide, take sodium metavanadate as 0.06 mmol, control the molar ratio of vanadium source and sulfur source to 1:2, add it to 20 ml absolute ethanol at the same time, Under magnetic stirring for 10 min to obtain suspension A;

[0041] (3) Add 0.004 g of ammonium fluoride to suspension A and stir for 1 h to obtain solution B;

[0042] (4) Put the stirred solution B and the metal nickel treated in step (1) into a high-pressure reactor, and then place it in an oven for reaction, and perform a solvothermal reaction at 100°C for a reaction time of 5 h ;

[0043] (5) After the reaction was completed, the reactor was cooled at room temperature, and the product was was...

Embodiment 3

[0046](1) Sonicate a (1×5) cm nickel mesh in acetone for 10 minutes, then immerse the nickel mesh in 3 mol / L hydrochloric acid for 15 minutes, and finally use ethanol and deionized water alternately Rinse 3 times and vacuum dry at 40°C for 10 hours to obtain the treated foamed nickel;

[0047] (2) Weigh sodium vanadate and sodium sulfide, take sodium vanadate as 0.08 mmol, control the molar ratio of vanadium source and sulfur source to 1:3, add it to 20 ml methanol at the same time, stir magnetically at room temperature for 15 min to obtain Suspension A;

[0048] (3) Add 0.006 g of ammonium fluoride to suspension A, stir for 2 h to obtain solution B;

[0049] (4) Put the stirred solution B and the metal nickel treated in step (1) into a high-pressure reactor, and then place it in an oven for reaction, and perform a solvothermal reaction at 120°C for a reaction time of 10 h ;

[0050] (5) After the reaction was completed, the reactor was cooled at room temperature, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com