Method for preparing silicon protective in-situ deposition photocatalytic functional textile

A technology of in-situ deposition and functional fabrics, applied in chemical instruments and methods, separation methods, textiles and papermaking, etc., to achieve the effects of convenient use, low cost and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

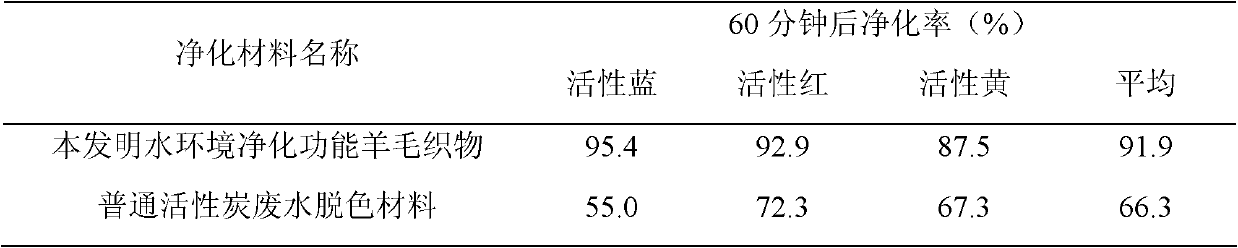

Embodiment 1

[0031] (1) Preparation of antioxidant finishing solution

[0032] Mix 500ml of absolute ethanol, 0.5ml of ammonia water, 200ml of distilled water and 100ml of acetone evenly, then add 20ml of tetraethyl orthosilicate drop by drop to configure a bionic protective anti-oxidation finishing solution;

[0033] (2) Protective finishing of wool fabric against photooxidation

[0034] Soak the wool fabric (1g) in the biomimetic protective anti-oxidation finishing solution, keep stirring at room temperature for 4 hours at 200rpm, take it out, rinse it with deionized water and ethanol, and dry it at 100°C;

[0035] (3) Preparation of Solution A

[0036] Under an argon atmosphere, add 0.005 mol of bismuth nitrate and 0.010 mol of disodium edetate into 50 ml of phosphate buffer solution, and dropwise add Tween 80, a wetting agent 2% relative to the weight of the fabric, and stir at 200 rpm for 30 min;

[0037] (4) Preparation of Solution B

[0038] Under an argon atmosphere, take 0.005m...

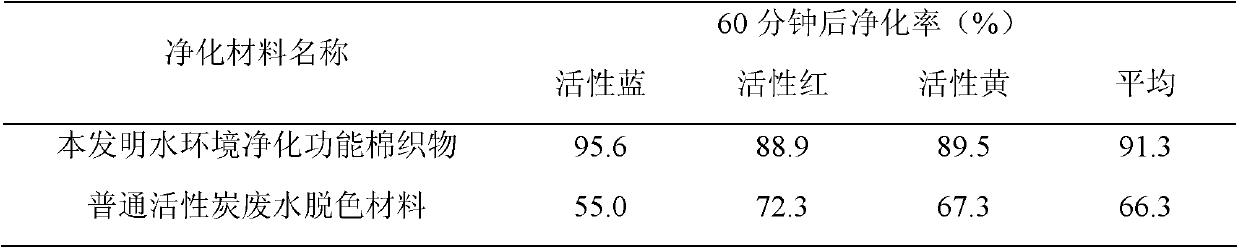

Embodiment 2

[0047] (1) Preparation of antioxidant finishing solution

[0048] Mix 600ml of absolute ethanol, 0.6ml of ammonia water, 200ml of distilled water and 100ml of acetone evenly, then add 20ml of diethylaminomethyltriethoxysilane drop by drop to configure a bionic protective anti-oxidation finishing solution;

[0049] (2) Protective finishing of cotton fabric against photooxidation

[0050] Soak the cotton fabric (1g) in the above-mentioned biomimetic protective anti-oxidation finishing solution, keep stirring at room temperature for 6 hours at 200rpm, take it out, rinse it with deionized water and ethanol, and dry it at 100°C;

[0051] (3) Preparation of Solution A

[0052] Under a nitrogen atmosphere, take 0.005mol of bismuth nitrate and 0.010mol of disodium edetate into 50ml of phosphate buffer solution, and dropwise add Tween 80, a wetting agent 3% relative to the weight of the fabric, and stir at 300rpm for 30min;

[0053] (4) Preparation of Solution B

[0054] Under a nit...

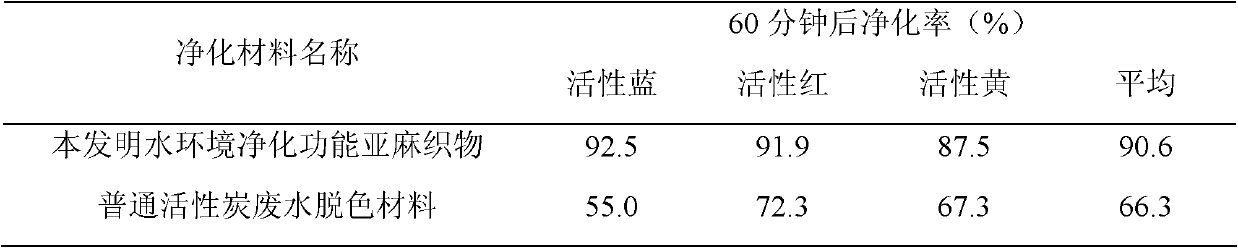

Embodiment 3

[0063] (1) Preparation of antioxidant finishing solution

[0064] Mix 500ml of absolute ethanol, 1ml of ammonia water, 200ml of distilled water and 100ml of acetone evenly, then add 20ml of sodium silicate drop by drop to configure a bionic protection and anti-oxidation finishing solution;

[0065] (2) Protective finishing of linen fabric against photooxidation

[0066] Immerse the linen fabric (1g) in the biomimetic protective anti-oxidation finishing solution, keep stirring at room temperature for 5 hours at 200rpm, take it out, rinse it with deionized water and ethanol, and dry it at 100°C;

[0067] (3) Preparation of Solution A

[0068] Under a nitrogen atmosphere, add 0.005 mol of bismuth nitrate and 0.010 mol of disodium ethylenediamine tetraacetate into 60 ml of phosphate buffer solution, and dropwise add Tween 80, a wetting agent 2% relative to the weight of the fabric, and stir at 200 rpm for 30 min;

[0069] (4) Preparation of Solution B

[0070] Under a nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com