Method for lowering unit energy consumption of high-silicon aluminum alloy microarc oxidation

A high-silicon aluminum alloy and micro-arc oxidation technology, which is applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of low pretreatment efficiency, large environmental pollution, low heat treatment efficiency, etc., and achieve a reduction in unit energy low energy consumption, high processing efficiency, and reduced adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment takes ZL104 aluminum alloy as an example. The content of each element on the surface of ZL104 aluminum alloy is shown in Table 1.

[0035] Table 1 The content of each element on the surface of ZL104

[0036]

[0037] It can be seen from Table 1 that the surface of ZL104 aluminum alloy mainly contains Al, Si and O, and its surface silicon content is 15.24%.

[0038] The method for reducing the unit energy consumption of high-silicon aluminum alloy micro-arc oxidation in this embodiment comprises the following steps:

[0039] (1) Prepare Ti / Zr pre-passivation film on the surface of high-silicon aluminum alloy:

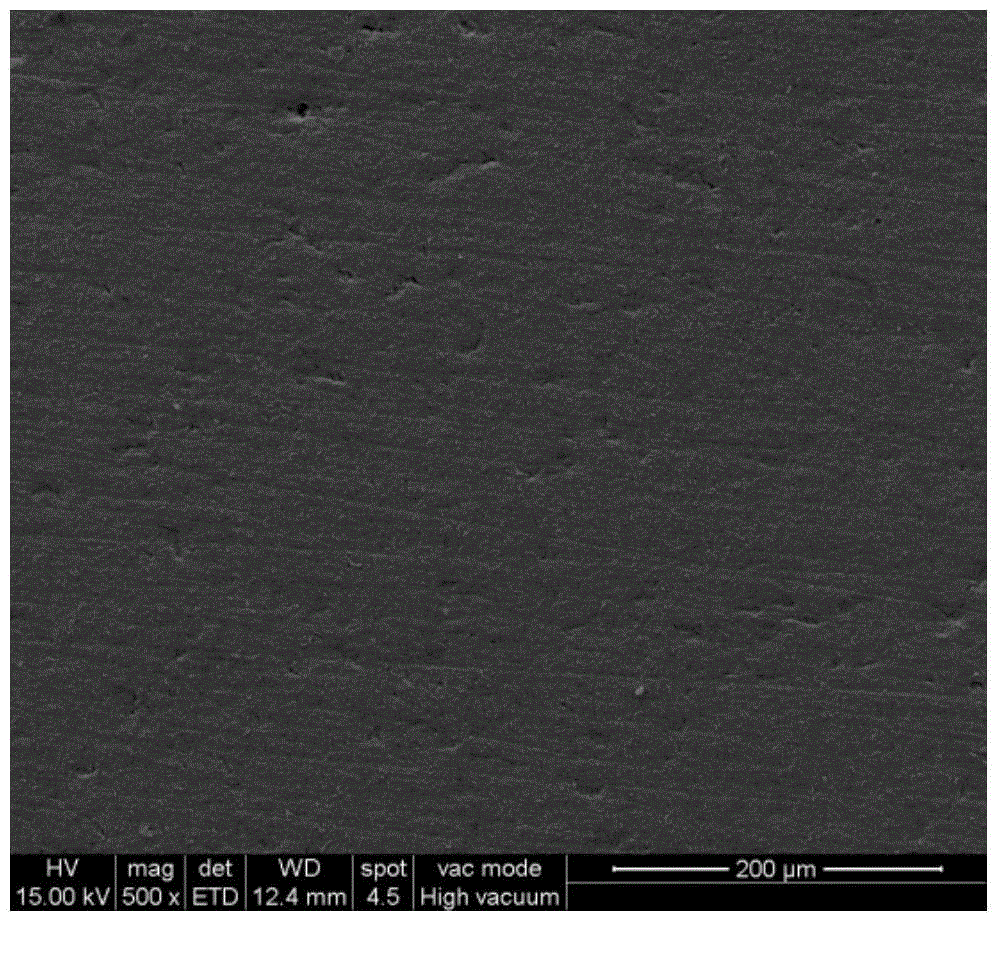

[0040] Continuously polish the ZL104 aluminum alloy with 100#, 400#, 600#, 800#, 1000# SiC sandpaper until the surface is smooth and the scratches are consistent; after industrial pickling and mixed pickling, and rinse the surface with distilled water, Soak in passivation solution to prepare titanium / zirconium passivation film; in passivation...

Embodiment 2

[0046] This embodiment takes ZL104 aluminum alloy as an example. The method for reducing the unit energy consumption of high-silicon aluminum alloy micro-arc oxidation in this embodiment comprises the following steps:

[0047] (1) Ti / Zr passivation film is prepared on the surface of ZL104 aluminum alloy:

[0048] Continuously polish the ZL104 aluminum alloy with 100#, 400#, 600#, 800#, 1000# SiC sandpaper until the surface is smooth and the scratches are consistent; after industrial pickling and mixed pickling, and rinse the surface with distilled water, Soak in passivation solution to prepare titanium / zirconium passivation film; in passivation solution, each liter of deionized water contains 4g tannic acid, 4g fluotitanic acid, 2g fluozirconic acid, 1g sodium metavanadate; after 3 minutes of film formation Take out and dry;

[0049] (2) Carry out micro-arc oxidation treatment: prepare micro-arc oxidation electrolyte, weigh 12g Na at room temperature 2 SiO 3 2. Dissolve 2g...

Embodiment 3

[0051] According to the method in Example 1, a high-silicon aluminum alloy covered with a pre-passivation film was prepared.

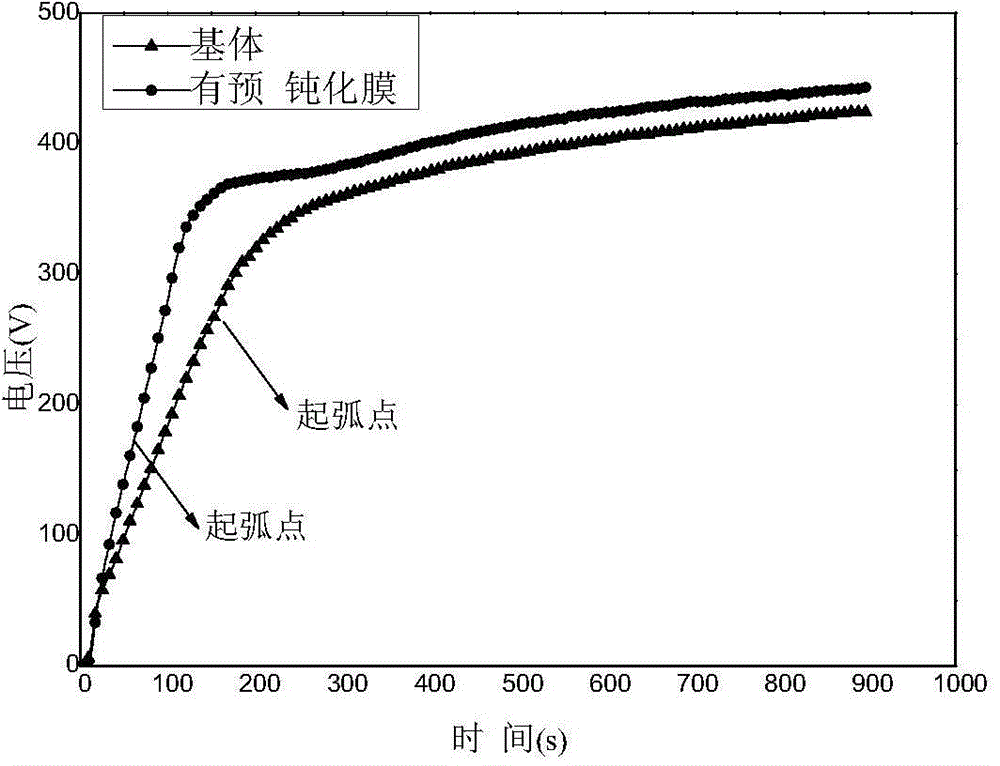

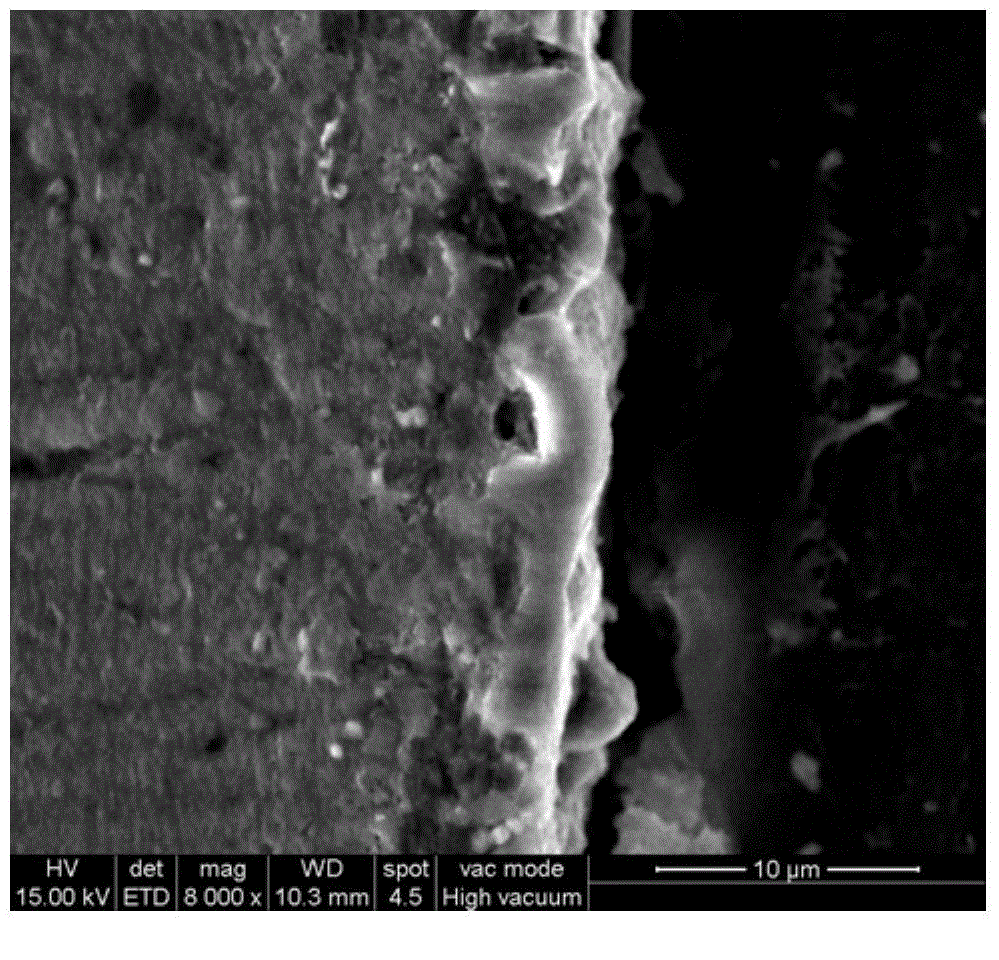

[0052] Prepare micro-arc oxidation electrolyte, weigh 8g Na at room temperature 2 SiO 3 1. Dissolve 1g NaOH in 1L deionized water, and use a magnetic stirrer to fully dissolve it. After the solution was prepared, the ZL104 aluminum alloy substrate and the high-silicon aluminum alloy covered with a pre-passivation film were subjected to micro-arc oxidation treatment using a bipolar pulse power supply. The relevant parameters were set as follows: the positive and negative current densities were 10A / dm 2 and 1A / dm 2 , frequency 400Hz, positive and negative duty cycle 30%, positive and negative pulse ratio 1:1, processing time 15min. After the micro-arc oxidation treatment, the sample is taken out, rinsed repeatedly with deionized water and dried to obtain the micro-arc oxidation ceramic film. The voltage-time curve in the micro-arc oxidation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com