Method for preparing high-corrosion-resistance colored passivating film on surface of aluminum alloy

An aluminum alloy surface, high corrosion resistance technology, applied in the direction of metal material coating process, etc., can solve the problems of reducing production efficiency, difficulty, and long film formation time, so as to improve production efficiency, improve corrosion resistance, and shorten production costs. The effect of membrane time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

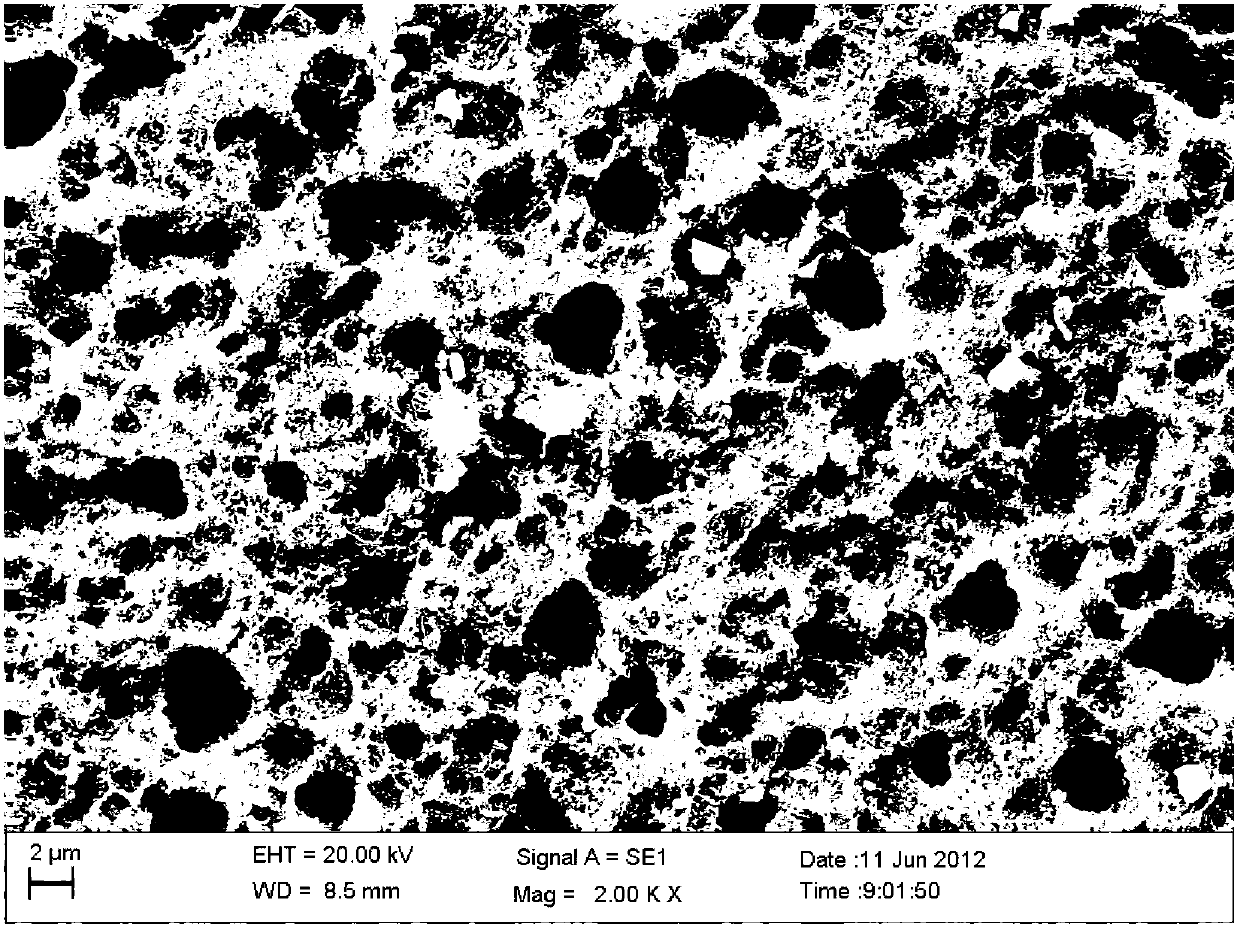

[0033] The method for preparing a highly corrosion-resistant colored passivation film on the surface of an aluminum alloy in this embodiment comprises the following steps:

[0034] (1) Pretreatment of the aluminum alloy surface: grinding the aluminum alloy surface to 1000#, followed by industrial pickling and mixed acid treatment;

[0035] Described industrial pickling is specifically:

[0036] Place the aluminum alloy in an acidic solution at 25°C for 1 minute, the composition of the acidic solution is 100g / L H 2 SO 4 , 20mL / L H 3 PO 4 , 0.3g / L OP-10, 6mL / L HF.

[0037] The mixed acid treatment is specifically:

[0038] The aluminum alloy was placed in a mixed acid solution at 25°C and immersed for 1 minute. The mixed acid solution consisted of 10%wt nitric acid, 2.5%wt phosphoric acid and 1.5%wt sulfuric acid.

[0039] (2) Dip the aluminum alloy treatment solution treated in step (1) at 30°C for 10 seconds to obtain a yellow passivation film containing zirconium, titan...

Embodiment 2

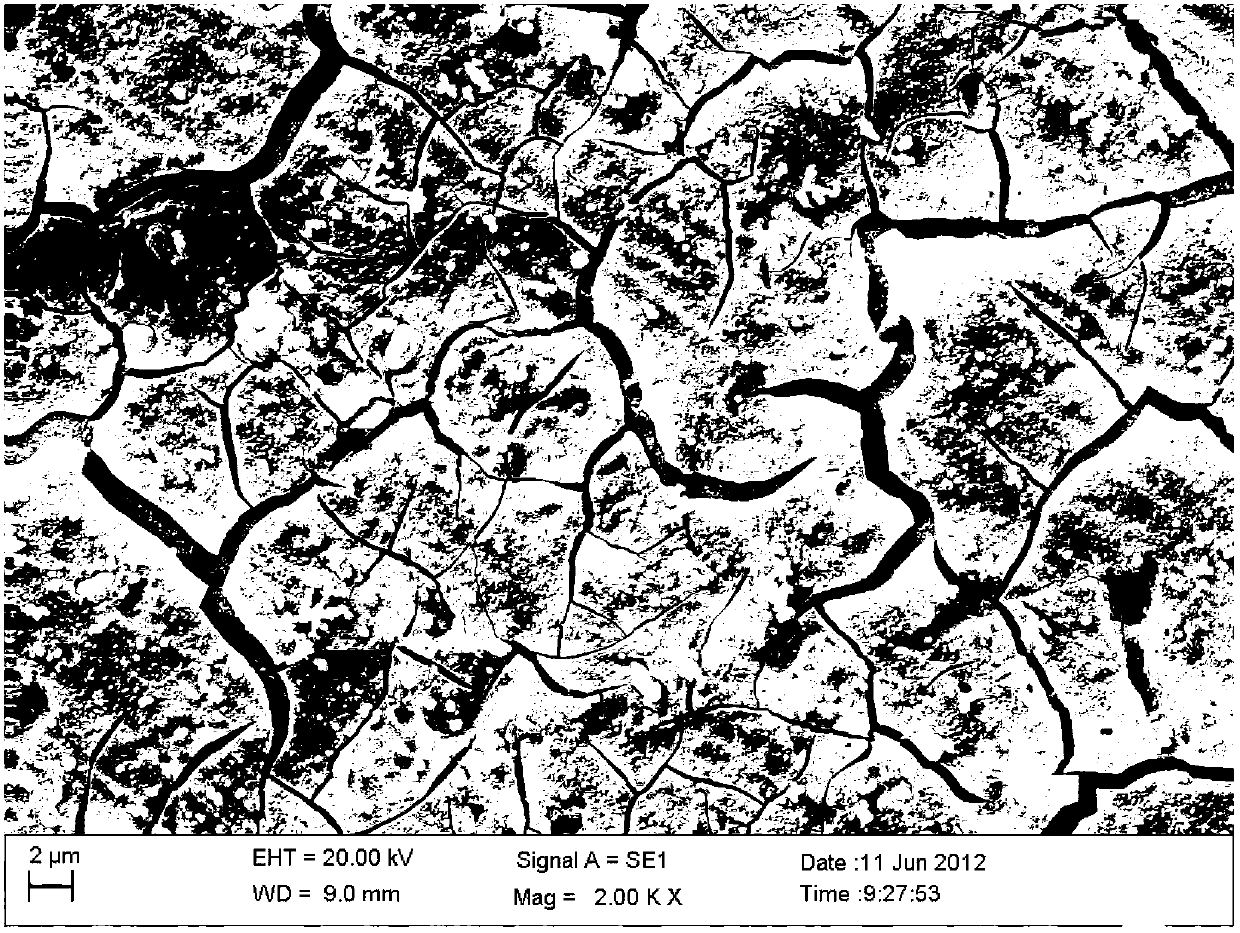

[0042] The method for preparing a highly corrosion-resistant colored passivation film on the surface of an aluminum alloy in this embodiment comprises the following steps:

[0043] (1) Pretreatment of the aluminum alloy surface: grinding the aluminum alloy surface to 1000#, followed by industrial pickling and mixed acid treatment;

[0044] Described industrial pickling is specifically:

[0045] Place the aluminum alloy in an acidic solution at 35°C for 3 minutes, the composition of the acidic solution is 100g / L H 2 SO 4 , 20mL / L H 3 PO 4 , 0.3g / L OP-10, 6mL / L HF.

[0046] The mixed acid treatment is specifically:

[0047] The aluminum alloy was placed in a mixed acid solution at 35°C and immersed for 3 minutes. The mixed acid solution consisted of 10%wt nitric acid, 2.5%wt phosphoric acid and 2%wt sulfuric acid.

[0048] (2) Dip the aluminum alloy treatment solution treated in step (1) at 30°C for 60s to obtain a yellow passivation film containing zirconium, titanium and...

Embodiment 3

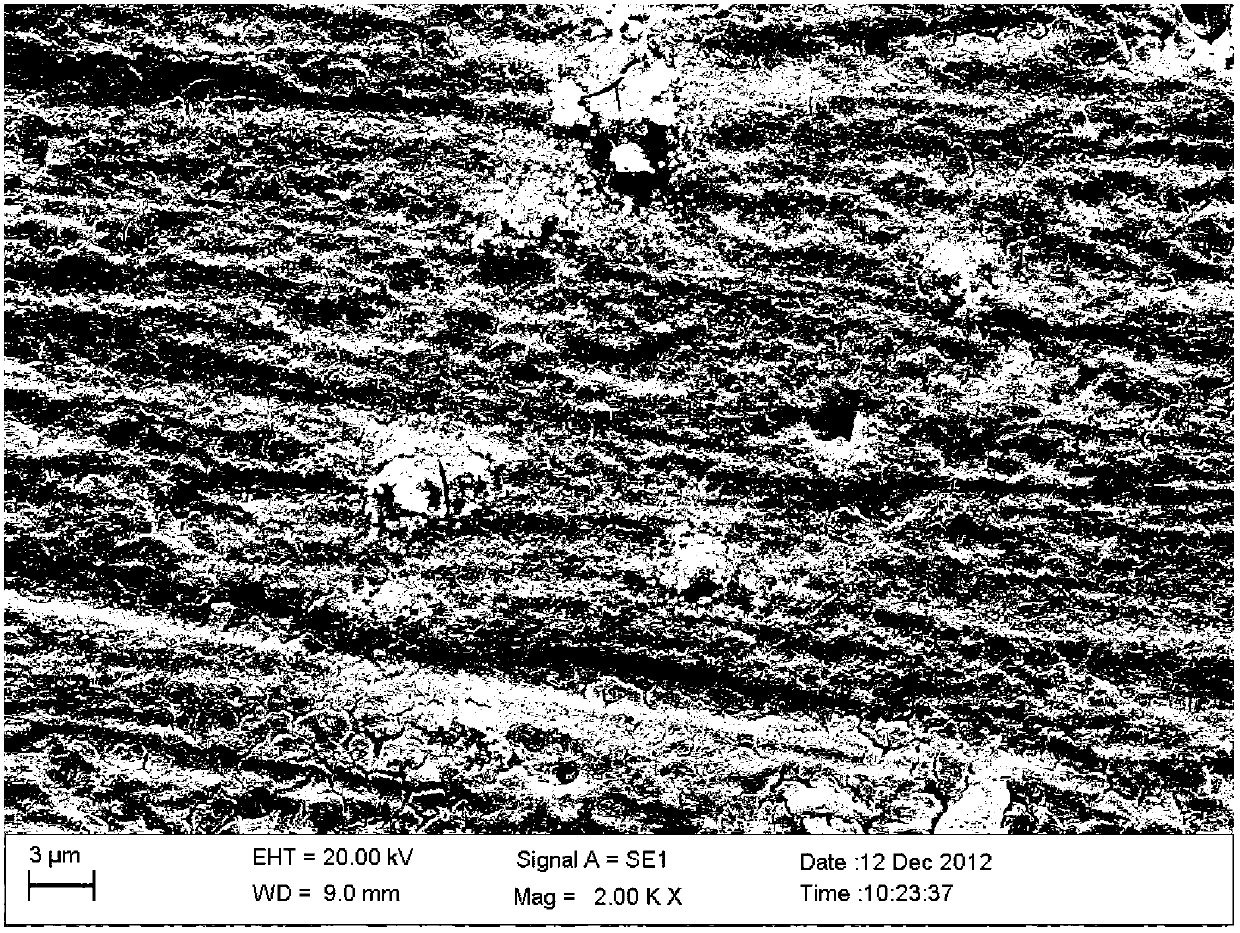

[0051] The method for preparing a highly corrosion-resistant colored passivation film on the surface of an aluminum alloy in this embodiment comprises the following steps:

[0052] (1) Pretreatment of the aluminum alloy surface: grinding the aluminum alloy surface to 1000#, followed by industrial pickling and mixed acid treatment;

[0053] (2) Dip the aluminum alloy treatment solution treated in step (1) at 50°C for 100s to obtain a yellow passivation film containing zirconium, titanium and vanadium on the surface of the aluminum alloy; the composition of the aluminum alloy treatment solution is as follows :

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com