Vanadium extracting method

An extraction method and technology of vanadium slag, applied in the field of vanadium extraction, can solve the problem that vanadium resources have not been recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

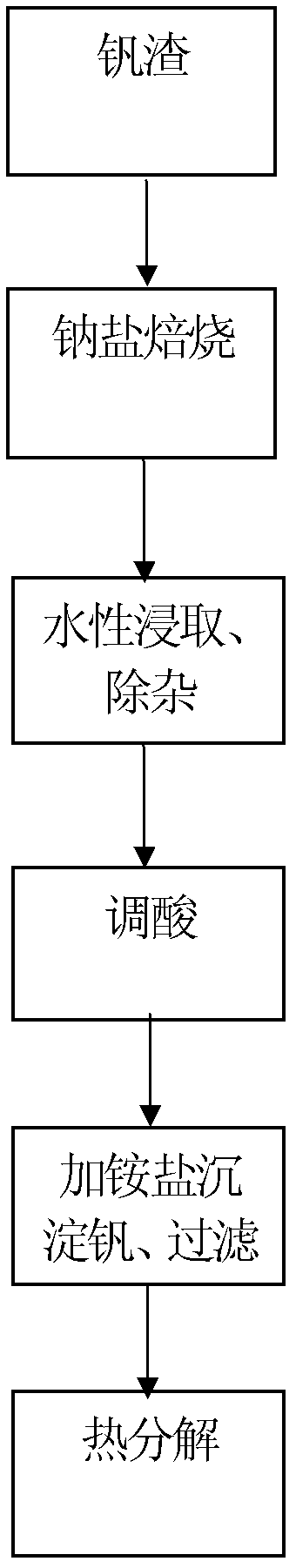

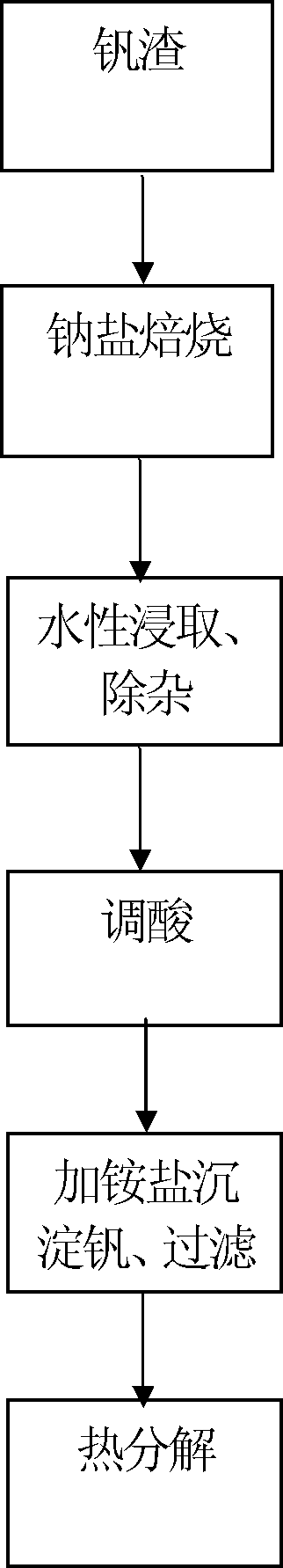

Method used

Image

Examples

Embodiment 1

[0043] After 1000kg of vanadium-containing blast furnace slag is added with 60kg of sodium chloride and mixed evenly, the residence time in the tunnel kiln is 50h, and it is roasted at 800°C for 8 hours; the aqueous leaching of the solid mixture after roasting adopts filling heap leaching method, the specific method is as follows: before charging, first fill the tank with a dilute vanadium aqueous solution of about 1m 3 In order to protect the filter layer; after loading, the sprinkler nozzle starts to spray hot dilute vanadium aqueous solution to the material column; the liquid output of the bottom outlet pipe is 1m per hour 3 , to get 85LNaVO 3 A leach solution with a concentration of 15g / L. Add a small amount of solid sodium carbonate to the leaching solution to adjust the pH value to 10, stir in the reactor for a period of time, pour it into a hopper with a filter cloth and a solution collector at the bottom, and filter to obtain 85L of filtrate; add a small amount of mag...

Embodiment 2

[0045] After 1000kg of vanadium-containing blast furnace slag is added with 50kg of sodium chloride and mixed evenly, the residence time in the tunnel kiln is 50h, and it is roasted under the firing zone of 800°C for 8 hours; the aqueous leaching of the solid mixture after roasting adopts filling heap leaching method, the specific method is as follows: before charging, first fill the tank with a dilute vanadium aqueous solution of about 1m 3 In order to protect the filter layer; after loading, the sprinkler nozzle starts to spray hot dilute vanadium aqueous solution to the material column; the liquid output of the bottom outlet pipe is 1m per hour 3 , get 80LNaVO 3 A leach solution with a concentration of 15g / L. Add a small amount of solid sodium carbonate to the leaching solution to adjust the pH value to 10, stir in the reactor for a period of time, pour it into a hopper with a filter cloth and a solution collector at the bottom, and filter to obtain 80L of filtrate; add a ...

Embodiment 3

[0047] After 1000kg of vanadium-containing blast furnace slag is added with 60kg of sodium chloride and mixed evenly, the residence time in the tunnel kiln is 50h, and it is roasted under the firing zone of 1000°C for 8 hours; the aqueous leaching of the solid mixture after roasting adopts filling heap leaching method, the specific method is as follows: before charging, first fill the tank with a dilute vanadium aqueous solution of about 1m 3 In order to protect the filter layer; after loading, the sprinkler nozzle starts to spray hot dilute vanadium aqueous solution to the material column; the liquid output of the bottom outlet pipe is 1m per hour 3 , to get 90LNaVO 3 A leach solution with a concentration of 15g / L. Add a small amount of solid sodium carbonate to the leaching solution to adjust the pH value to 10, stir in the reactor for a period of time, pour it into a hopper with a filter cloth and a solution collector at the bottom, and filter to obtain 90L of filtrate; ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com