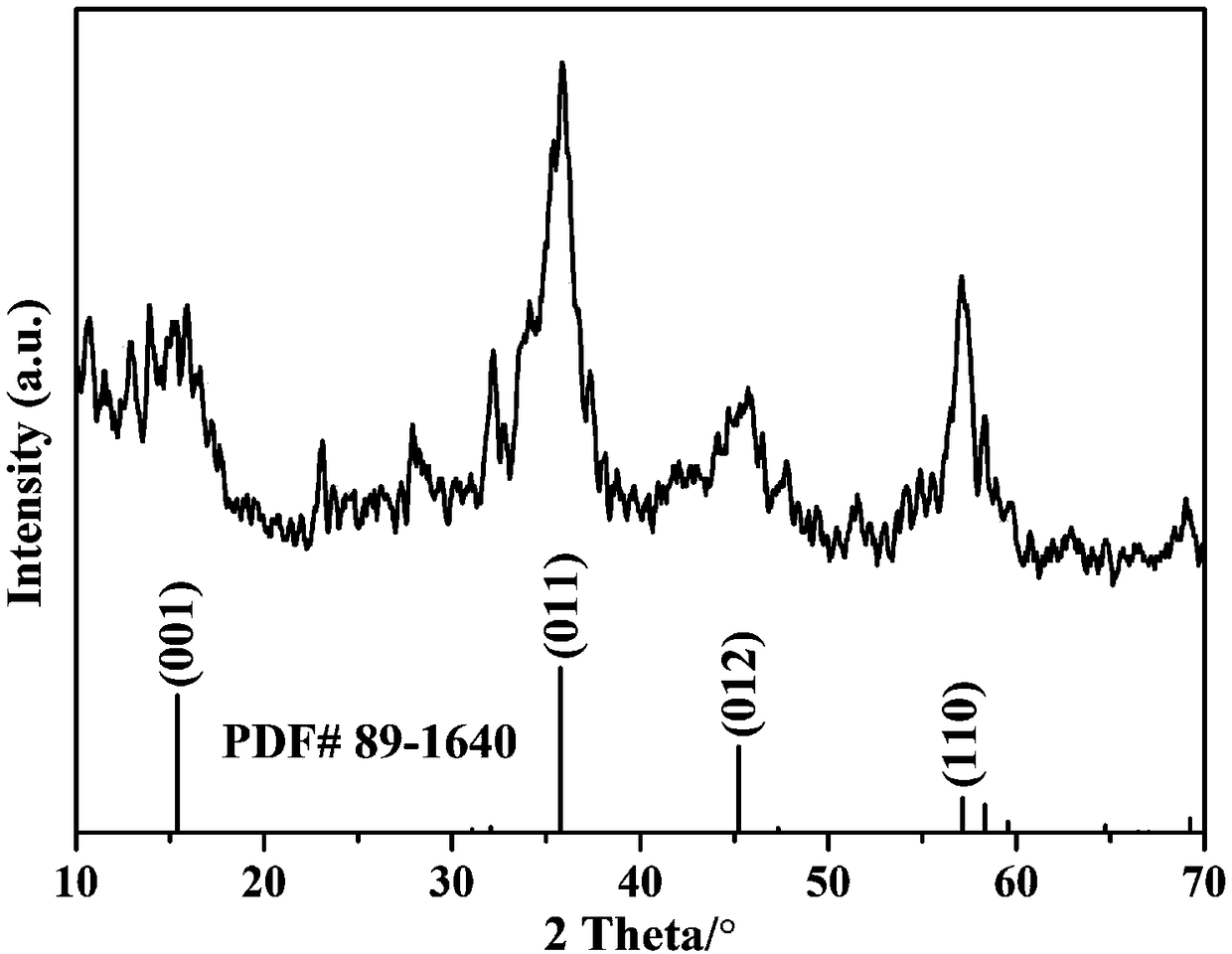

Ultra-small nanosheet self-assembled flower-like VS2 powder and preparation method thereof

An ultra-small nanometer, self-assembly technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of high yield, uniform chemical composition, and no post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Add 1.0 g of sodium metavanadate and 3.6 g of thioacetamide to 50 ml of nitrogen methyl pyrrolidone at the same time, and magnetically stir at a speed of 500 r / min at room temperature to obtain solution A;

[0037] Step 2: Pour solution A into the reaction liner at a filling ratio of 50% and seal it, then install the liner in the outer kettle and fix it in a homogeneous reactor, and then under the condition of a rotating speed of 10r / min, React at 180°C for 24h;

[0038] Step 3: After the reaction, the reaction kettle is naturally cooled to room temperature, and then the product cooled after the reaction is taken out, and the product is collected after being alternately washed with water and alcohol for 3 times by means of suction filtration;

[0039] Step 4: Place the collected product in the cold well of a freeze dryer at -50°C, freeze for 4 hours, then place the frozen product in a tray, seal it with plastic wrap, and pierce the plastic wrap to ensure its Fu...

Embodiment 2

[0051] Step 1: Add 0.9 g of sodium metavanadate and 3.4 g of thioacetamide to 48 ml of nitrogen methyl pyrrolidone at the same time, and magnetically stir at a speed of 400 r / min at room temperature to obtain solution A;

[0052] Step 2: Pour solution A into the reaction liner at a filling ratio of 49% and seal it, then install the liner in an outer kettle and fix it in a homogeneous reactor, and then under the condition of a rotating speed of 8r / min, React at 175°C for 25h;

[0053] Step 3: After the reaction, the reaction kettle is naturally cooled to room temperature, and then the product cooled after the reaction is taken out, and the product is collected after being alternately washed with water and alcohol for 4 times by means of suction filtration;

[0054] Step 4: Place the collected product in the cold well of a freeze dryer at -40°C, freeze for 5 hours, then place the frozen product in a tray, seal it with plastic wrap, and pierce the plastic wrap to ensure its Full...

Embodiment 3

[0056] Step 1: Add 1.1 g of sodium metavanadate and 3.8 g of thioacetamide to 52 ml of nitrogen methyl pyrrolidone at the same time, and magnetically stir at a speed of 600 r / min at room temperature to obtain solution A;

[0057] Step 2: Pour solution A into the reaction liner at a filling ratio of 52% and seal it, then install the liner in an outer kettle and fix it in a homogeneous reactor, and then at a speed of 5 r / min, React at 185°C for 23h;

[0058] Step 3: After the reaction, the reaction kettle is naturally cooled to room temperature, and then the product cooled after the reaction is taken out, and the product is collected after being alternately washed with water and alcohol for 5 times by suction filtration;

[0059] Step 4: Place the collected product in the cold well of a freeze dryer at -60°C, freeze for 2 hours, then place the frozen product in a tray, seal it with plastic wrap, and pierce the plastic wrap to ensure its Fully dry under low pressure conditions, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com