Preparation method of nanosheet self-assembled frustum-shaped (NH4)2V3O8

A self-assembly, nanosheet technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of few reports and few electrochemical performances, and achieve good electrochemical performance, low preparation cost, and cheap raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A nanosheet self-assembled prism (NH 4 ) 2 V 3 o 8 The preparation method comprises the following steps:

[0021] (1) Dissolve the vanadium source in deionized water to prepare a suspension A. At this time, the concentration of vanadium is 0.108-1mol / L, then add ammonia water and organic alcohol to the suspension A in turn, and stir until the vanadium source is completely dissolved. , to obtain solution B. The vanadium source is vanadium pentoxide, sodium metavanadate or ammonium metavanadate; the organic alcohol is ethylene glycol, ethanol or isopropanol.

[0022] Further, the stirring method is magnetic stirring or ultrasonic vibration. The speed of the magnetic stirring is 400-900 r / min; the ultrasonic vibration time is 10-60 min.

[0023] (2) Put solution B into a hydrothermal reaction kettle, place it in a homogeneous reactor, and react for 6-24 hours at a temperature of 120-200°C.

[0024] (3) Cool naturally after the reaction is complete, and then use suct...

Embodiment 1

[0027] Step 1: Put 1gV 2 o 5 Dissolve in deionized water to prepare suspension A. At this time, the concentration of vanadium is 0.3mol / L, then add 9mL ammonia water to suspension A and ultrasonically vibrate for 10min, then add 10mL ethylene glycol and ultrasonically vibrate for 30min until V 2 o 5 Completely dissolved to obtain solution B. Vanadium pentoxide can be replaced by sodium metavanadate or ammonium metavanadate; ethylene glycol can be replaced by ethanol or isopropanol.

[0028] Step 2: Put solution B into a hydrothermal reaction kettle, place it in a homogeneous reactor, and react for 12 hours at a temperature of 160°C.

[0029]Step 3: Cool naturally after the reaction is complete, then wash the product 3 times with water and 3 times with alcohol, then collect the washed product and place it in an oven, and dry it at 60°C for 12 hours to obtain nanosheets Self-assembled prisms (NH 4 ) 2 V 3 o 8 .

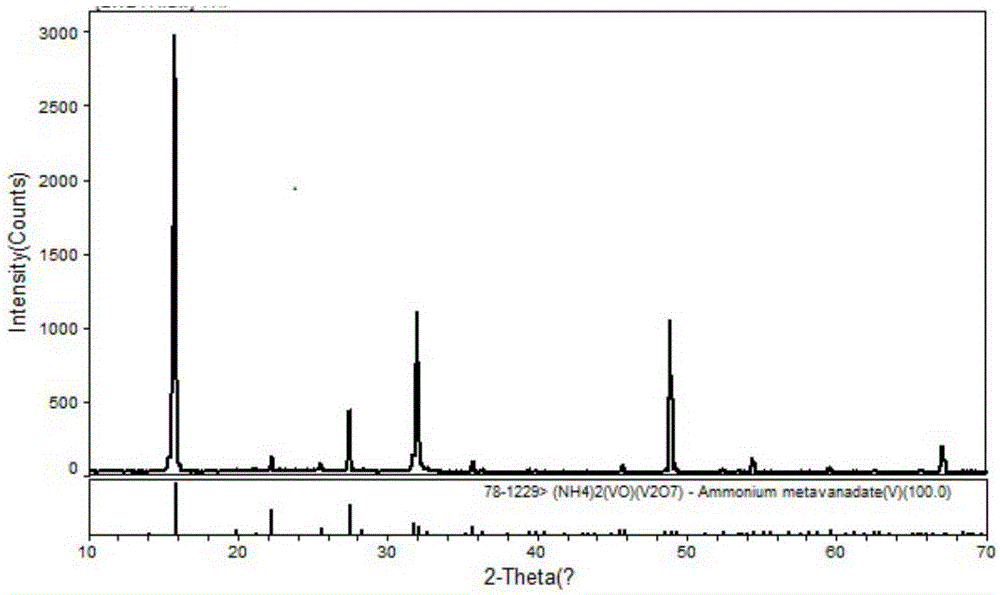

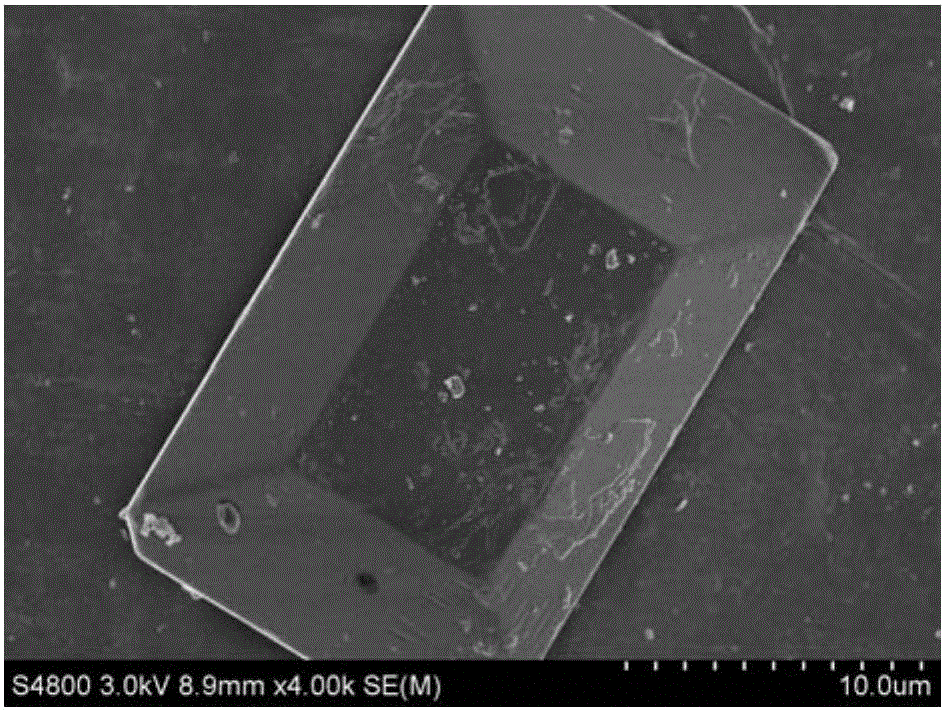

[0030] From figure 1 It can be seen that the (NH 4 ) 2...

Embodiment 2

[0033] step one:

[0034] Will 0.5g V 2 o 5 Dissolve in deionized water to prepare suspension A. At this time, the concentration of vanadium is 0.108mol / L, then add 3mL ammonia water to suspension A and stir magnetically for 5min, then add 5mL ethylene glycol and magnetically stir for 10min until V 2 o 5 Completely dissolved to obtain solution B. The rotating speed of magnetic stirring is 400r / min~600r / min. Vanadium pentoxide can be replaced by sodium metavanadate or ammonium metavanadate; ethylene glycol can be replaced by ethanol or isopropanol.

[0035] Step 2: Put solution B into a hydrothermal reaction kettle, place it in a homogeneous reactor, and react for 6 hours at a temperature of 120°C.

[0036] Step 3: Cool naturally after the reaction is complete, then wash the product twice with water and twice with alcohol, then collect the washed product, place it in an oven, and dry it at 80°C for 6 hours to obtain nanosheets Self-assembled prisms (NH 4 ) 2 V 3 o 8 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com