Method for extracting microalgal oil by supercritical CO2 isothermal transformation technology

A microalgae oil and supercritical technology, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of uneven extraction effect and solvent residue, and achieve the effects of excellent product quality, prevention of poisoning, and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Raw material pretreatment

[0031] The dried microalgae raw materials are removed from impurities, pulverized and ground, passed through a 150-mesh sieve (particle size 106 μm), and the under-sieve is removed for supercritical extraction.

[0032] 2. Microalgae filling

[0033] Put the pulverized microalgae fine dry powder into the extraction kettle 6, the filling factor is 80%, and cover the sealing cover of the extraction kettle after filling.

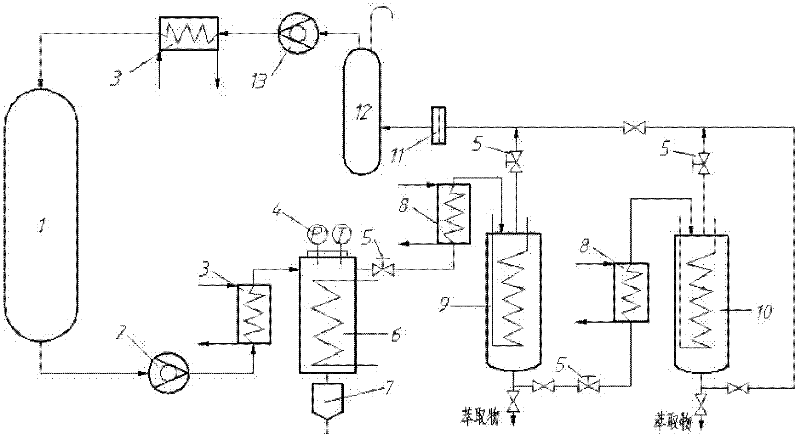

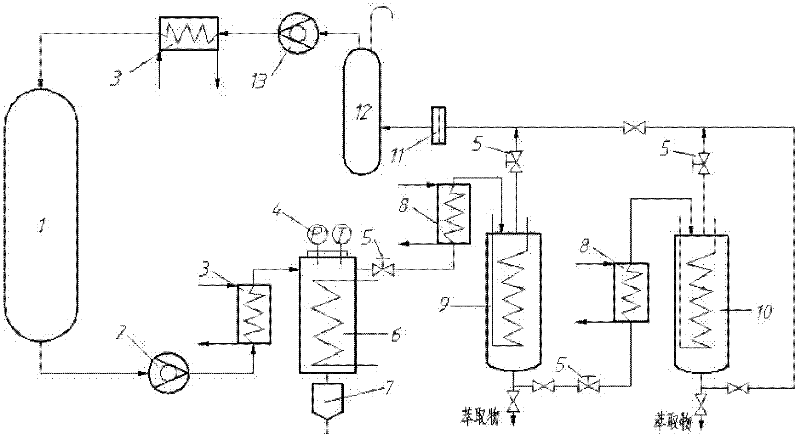

[0034] 3. Extraction

[0035] will CO 2 CO in tank 1 2 After being compressed by the high-pressure compressor 2 and cooled by the cooler 3 to reach a supercritical state, it is injected into the extraction kettle 6 for extraction. The pressure in the extraction kettle was kept at 18MPa, the extraction temperature was kept at 38°C, and the extraction time was controlled at 150min.

[0036] 4. Oil separation

[0037] After the extraction operation was completed, the extraction residue in the extraction kettle 6 was disc...

Embodiment 2

[0040]1. Raw material pretreatment

[0041] The dried microalgae raw materials are removed from impurities, pulverized and ground, passed through a 200-mesh sieve (75 μm in particle size), and the under-sieve is removed for supercritical extraction.

[0042] 2. Microalgae filling

[0043] Put the pulverized microalgae fine dry powder into the extraction kettle 6, the filling factor is 85%, and cover the sealing cover of the extraction kettle after filling.

[0044] 3. Extraction

[0045] will CO 2 CO in tank 1 2 After being compressed by the high-pressure compressor 2 and cooled by the cooler 3 to reach a supercritical state, it is injected into the extraction kettle 6 for extraction. The pressure in the extraction kettle was kept at 20MPa, the extraction temperature was kept at 42°C, and the extraction time was controlled at 160min.

[0046] 4. Oil separation

[0047] After the extraction operation was completed, the extraction residue in the extraction kettle 6 was dis...

Embodiment 3

[0050] 1. Raw material pretreatment

[0051] The dry raw material of microalgae is impurity-removed, crushed and ground, passed through a 250-mesh sieve (particle size 58 μm), and the under-sieve is removed for supercritical extraction.

[0052] 2. Microalgae filling

[0053] Put the pulverized microalgae fine dry powder into the extraction kettle 6, the filling coefficient is 83%, and cover the sealing cover of the extraction kettle after filling.

[0054] 3. Extraction

[0055] will CO 2 CO in tank 1 2 After being compressed by the high-pressure compressor 2 and cooled by the cooler 3 to reach a supercritical state, it is injected into the extraction kettle 6 for extraction. The pressure in the extraction kettle was kept at 25MPa, the extraction temperature was kept at 34°C, and the extraction time was controlled at 180min.

[0056] 4. Oil separation

[0057] After the extraction operation was completed, the extraction residue in the extraction kettle 6 was discharged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com