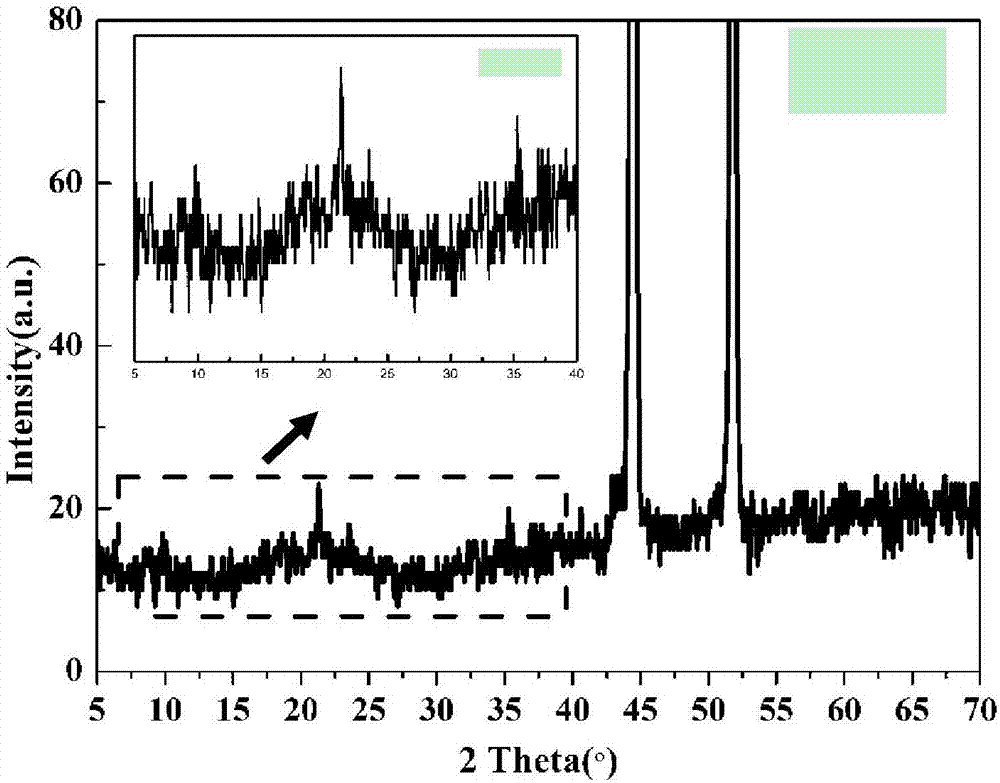

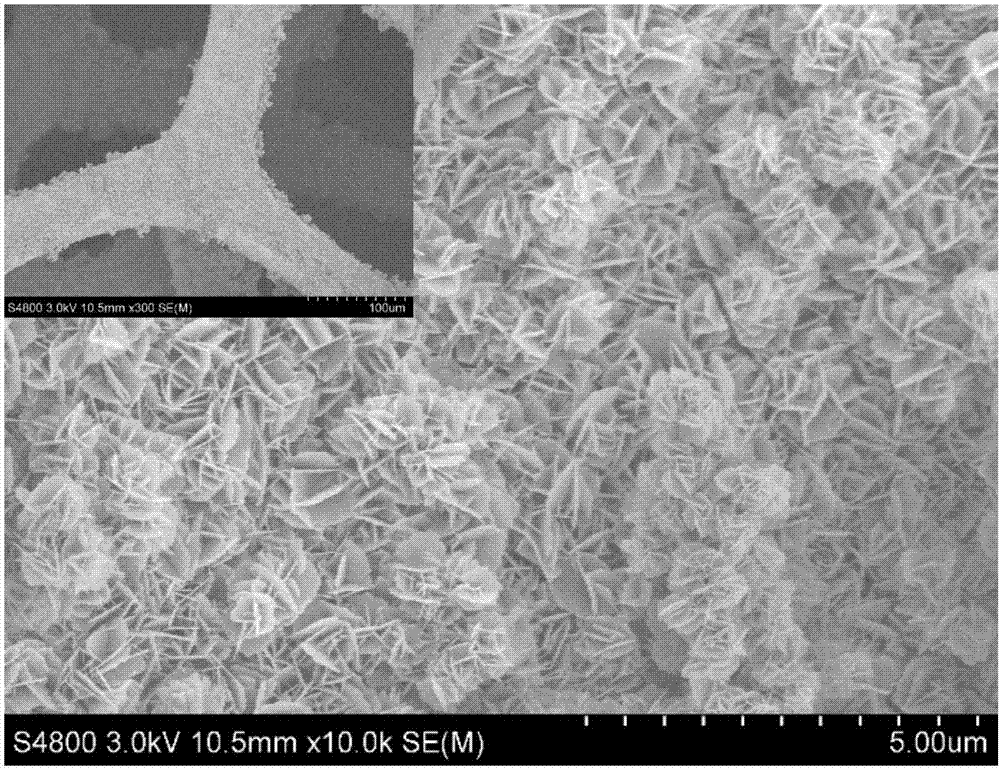

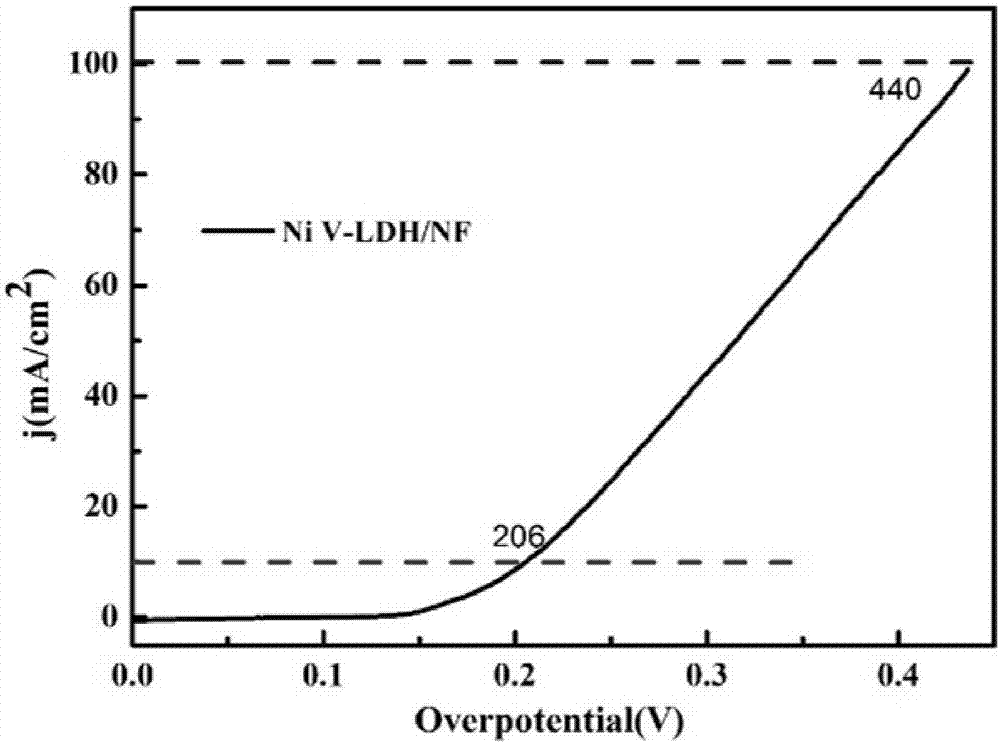

Preparation method of nickel/vanadium layered double hydroxide nano-sheet array water oxidation catalyst

A nanosheet array, hydroxide technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of uneven product distribution and uneven product morphology. Regularity, complex preparation process and other problems, to achieve the effect of being conducive to full contact, uniform morphology, and uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Sonicate 2×5 cm of nickel foam in pure acetone solution for 10 minutes, then immerse the nickel foam in 2mol / L hydrochloric acid for ultrasonic cleaning, and finally wash it with ethanol and deionized water alternately, and finally clean it at 25°C Vacuum drying 10h obtains the foamed nickel after processing;

[0024] 2) Take NiCl according to the molar ratio of 2:0.5:5 2 ·6H 2 O, VCl 3 and Co(NH 2 ) 2 At the same time, add it to deionized water so that the concentration of the nickel source is 0.1mol / L, and stir magnetically at room temperature to obtain a clear solution A;

[0025] 3) Put the nickel foam treated in step 1) into the reaction liner, then pour solution A into the reaction liner and seal it. The reaction filling ratio should be controlled at 20%, and then the inner liner is fixed in the outer kettle After placing it in a homogeneous reactor, then carry out a hydrothermal reaction at 90°C;

[0026] 4) After the hydrothermal reaction is completed, ...

Embodiment 2

[0028] 1) Sonicate 2×5 cm of nickel foam in pure acetone solution for 10 minutes, then immerse the foam nickel in 3mol / L hydrochloric acid for ultrasonic cleaning, and finally wash it with ethanol and deionized water alternately, and finally clean it at 25°C Vacuum drying 12h obtains the foamed nickel after processing;

[0029] 2) Take NiCl according to the molar ratio of 2.5:1:5.5 2 ·6H 2 O, VCl 3 and Co(NH 2 ) 2 At the same time, add it to deionized water so that the concentration of the nickel source is 0.15mol / L, and magnetically stir at room temperature to obtain a clear solution A;

[0030] 3) Put the nickel foam treated in step 1) into the reaction liner, then pour solution A into the reaction liner and seal it. The reaction filling ratio should be controlled at 50%, and then the inner liner is fixed in the outer kettle After placing it in a homogeneous reactor, then carry out a hydrothermal reaction at 110°C;

[0031] 4) After the hydrothermal reaction is complet...

Embodiment 3

[0033] 1) Sonicate 2×5 cm of nickel foam in pure acetone solution for 10 minutes, then immerse the foam nickel in 3mol / L hydrochloric acid for ultrasonic cleaning, and finally wash it with ethanol and deionized water alternately, and finally clean it at 25°C Vacuum drying 12h obtains the foamed nickel after processing;

[0034] 2) Take NiCl according to the molar ratio of 3:1.5:6 2 ·6H 2 O, VCl 3 and Co(NH 2 ) 2 At the same time, add it to deionized water so that the concentration of the nickel source is 0.2mol / L, and stir magnetically at room temperature to obtain a clear solution A;

[0035] 3) Put the nickel foam treated in step 1) into the reaction lining, then pour solution A into the reaction lining and seal it. The reaction filling ratio should be controlled at 60%, and then the inner lining is fixed in the outer kettle After placing it in a homogeneous reactor, then carry out a hydrothermal reaction at 130°C;

[0036] 4) After the hydrothermal reaction is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com