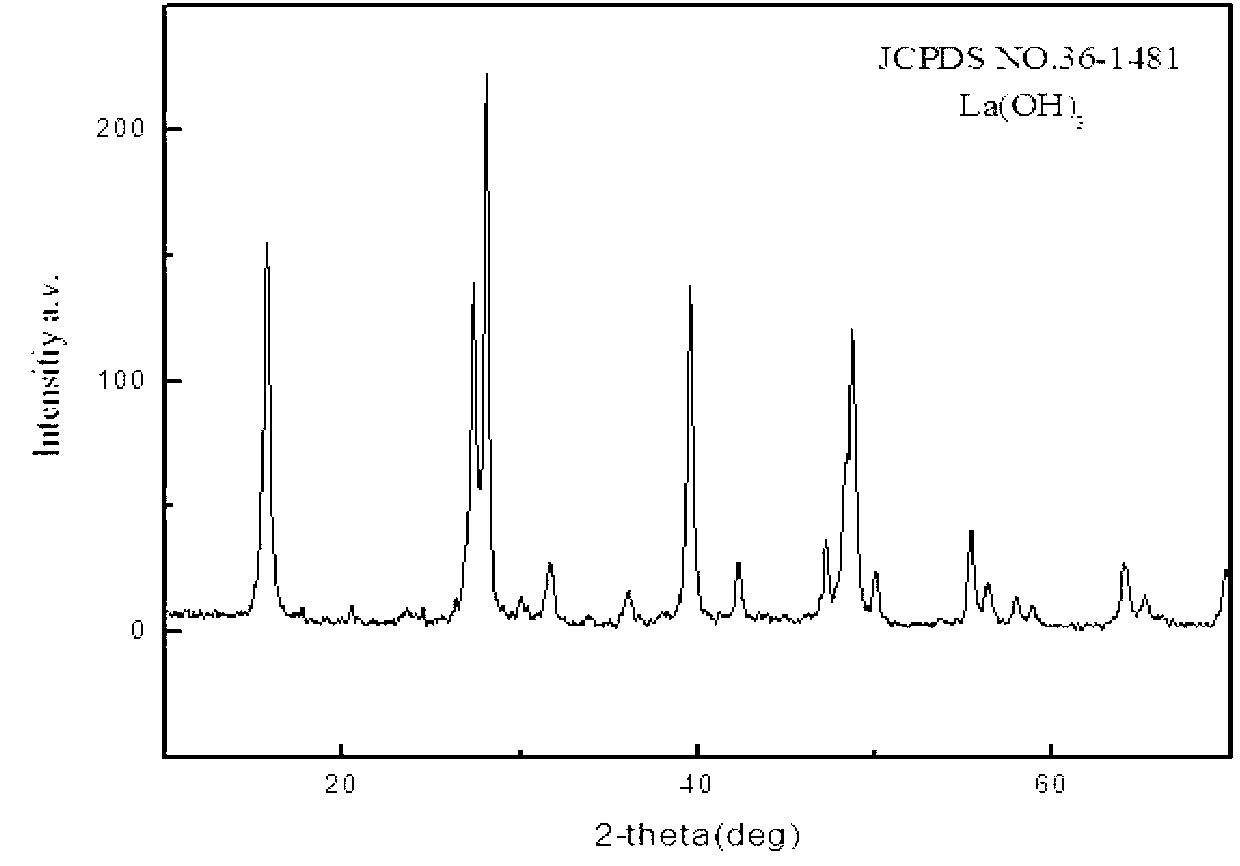

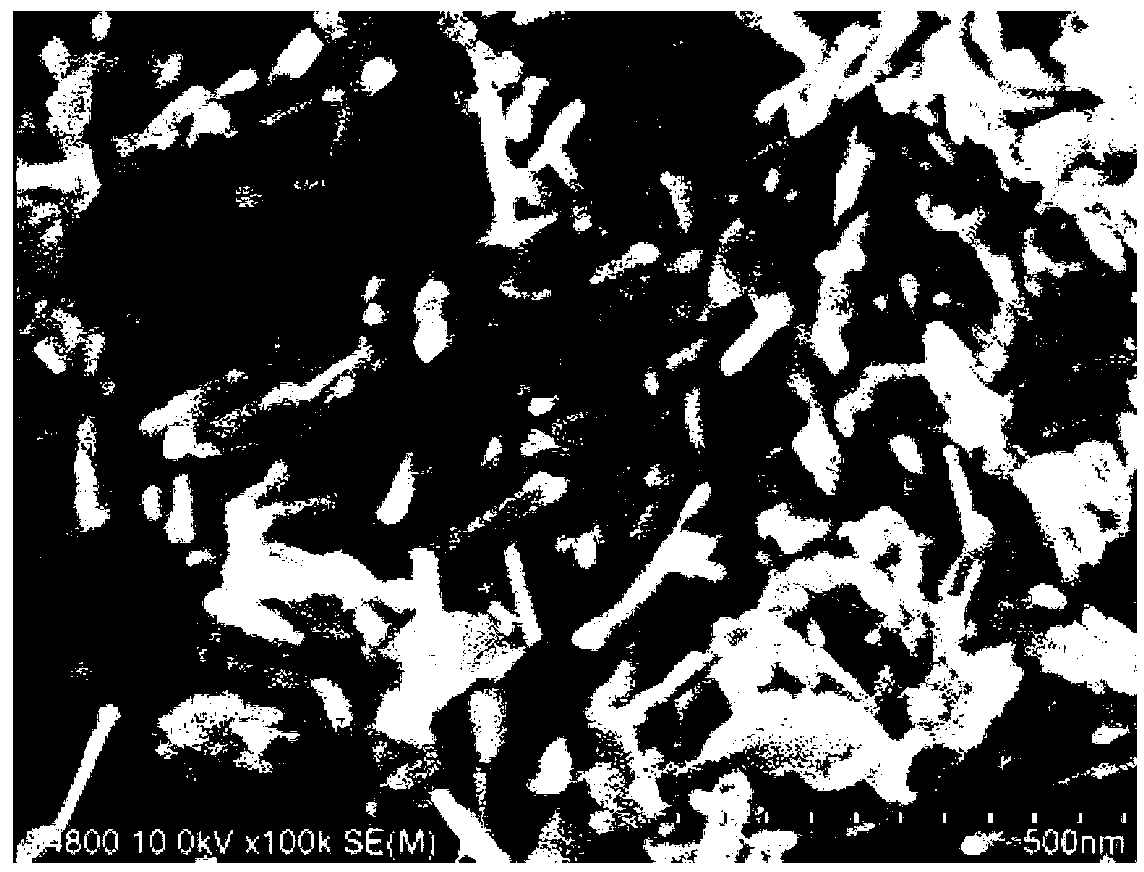

Method for preparing platy lanthanum hydroxide nanocrystalline through microwave-ultrasonic method

A technology of lanthanum hydroxide and ultrasonic method, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of long reaction time under experimental conditions, poor product dispersibility, small specific surface area of samples, etc., and achieve dispersibility Good, short reaction time cycle, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Analytical pure lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) added to deionized water to make a transparent solution A with a concentration of 0.05mol / L;

[0021] 2) Add analytically pure polyethylene glycol (PEG) to solution A so that the concentration of PEG in the solution is 0.005mol / L to obtain solution B;

[0022] 3) Add potassium hydroxide or sodium hydroxide solution to solution B to make La 3+ / OH - The molar ratio of is 1:10, magnetic stirring forms precursor solution C;

[0023] 4) Pour the precursor solution C into a four-neck round bottom flask, put it into the UWave-1000 microwave-ultraviolet-ultrasonic trinity synthesis reaction instrument, select the combination of microwave heating and ultrasonic wave in the temperature-time mode, the temperature -The temperature of the time mode is controlled at 160°C, the reaction time is controlled at 120min, and naturally cooled to room temperature after the reaction;

[0024] 5) The product was coll...

Embodiment 2

[0026] 1) Analytical pure lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) added to deionized water to make a transparent solution A with a concentration of 0.1mol / L;

[0027] 2) Add analytically pure polyethylene glycol (PEG) to solution A so that the concentration of PEG in the solution is 0.007mol / L to obtain solution B;

[0028] 3) Add potassium hydroxide or sodium hydroxide solution to solution B to make La 3+ / OH - The molar ratio of is 1:15, magnetic stirring forms precursor solution C;

[0029] 4) Pour the precursor solution C into a four-neck round bottom flask, put it into the UWave-1000 microwave-ultraviolet-ultrasonic trinity synthesis reaction instrument, select the combination of microwave heating and ultrasonic wave in the temperature-time mode, the temperature -The temperature in the time mode is controlled at 180°C, the reaction time is controlled at 100min, and naturally cooled to room temperature after the reaction;

[0030] 5) The product was colle...

Embodiment 3

[0032] 1) Analytical pure lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) added to deionized water to make a transparent solution A with a concentration of 0.5mol / L;

[0033] 2) Add analytically pure polyethylene glycol (PEG) to solution A so that the concentration of PEG in the solution is 0.008mol / L to obtain solution B;

[0034] 3) Add potassium hydroxide or sodium hydroxide solution to solution B to make La 3+ / OH - The molar ratio of is 1:20, magnetic stirring forms precursor solution C;

[0035] 4) Pour the precursor solution C into a four-neck round bottom flask, put it into the UWave-1000 microwave-ultraviolet-ultrasonic trinity synthesis reaction instrument, select the combination of microwave heating and ultrasonic wave in the temperature-time mode, the temperature -The temperature of the time mode is controlled at 200°C, the reaction time is controlled at 80 minutes, and naturally cooled to room temperature after the reaction;

[0036] 5) The product was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com