Metal three-dimensional additive manufacturing apparatus and method

A kind of additive manufacturing and three-dimensional technology, which is applied in the field of metal additive manufacturing devices, can solve the problems that cannot meet the engineering application requirements, selectivity (low processing accuracy, poor surface quality of molded parts, etc.), and achieve good compactness and grain structure. The effect of thinning and high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

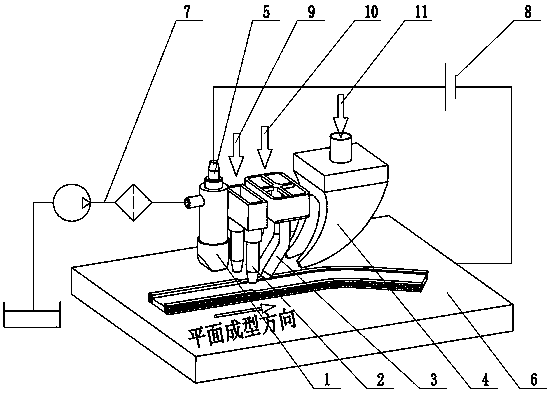

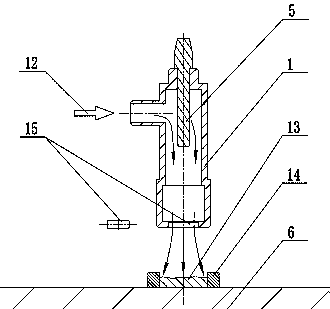

[0034] The metal three-dimensional additive manufacturing device of the present invention includes a jet nozzle 1, which is made of polypropylene, and a conductor 5 made of platinum is arranged inside. The shape of the nozzle 15 is a rectangle with a width of 2mm and a length of 10mm, and the distance between the outlet and the cathode base The height of 6 is 2mm; the film-forming nozzle 2 is provided with 2 nozzles communicating with the industrial paraffin in the hot-melt state, the distance between the nozzles is 10mm, and the distance can be adjusted within the range of 1-10mm, and the height between the outlet and the cathode base is 0.1mm; The air jet nozzle 3 connected with hot air and the cleaning nozzle 4 connected to the deionized water source are also provided with 2 nozzles, the distance between the nozzles and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com