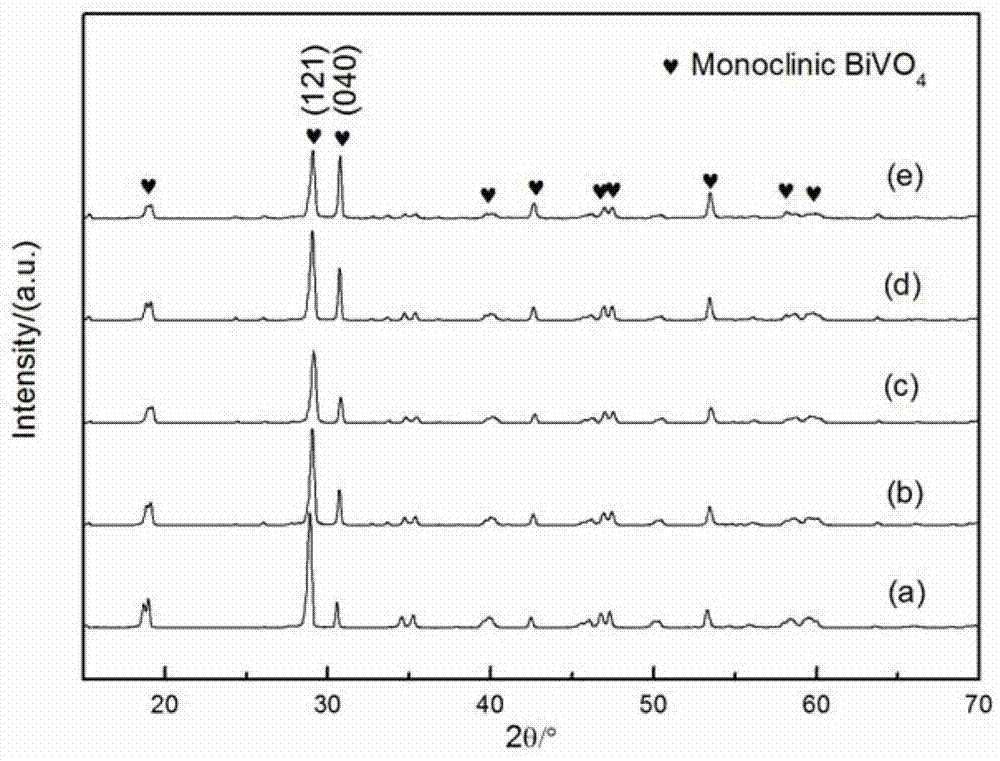

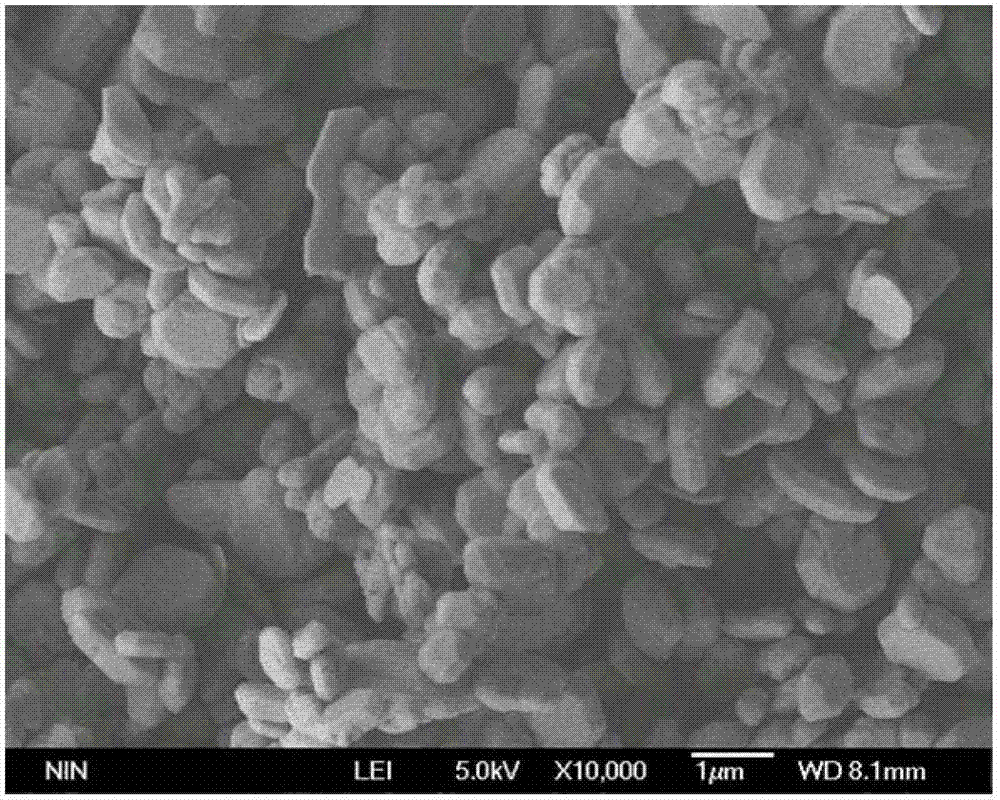

Preparation method of cake-piece-shaped N/BiVO4 photocatalyst growing along high-activity (040) crystal orientation

A crystal plane orientation, photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low photocatalytic activity and achieve crystal crystallization High density, uniform particle size and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

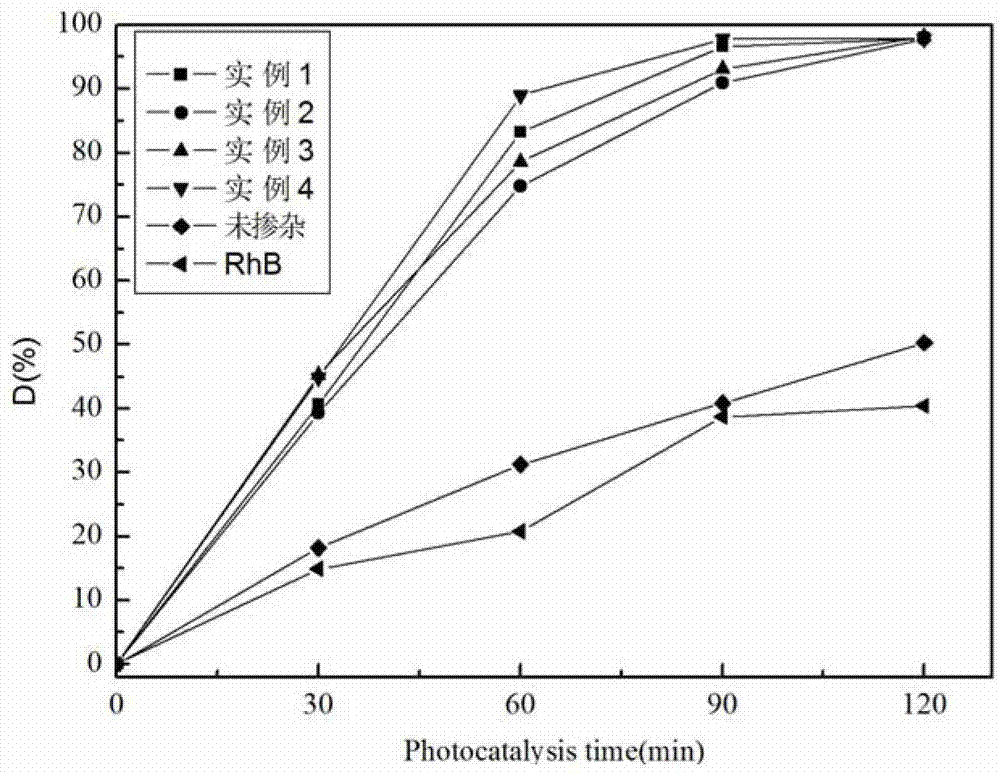

Examples

Embodiment 1

[0022] Step 1: Add 0.01mol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20ml of deionized water, stirred for 30min to obtain a bismuth salt solution, and 0.01mol of NH 4 VO 3 Dissolve in 20ml of 80°C deionized water, heat and stir for 20 minutes to obtain a vanadium salt solution, mix the bismuth salt solution and vanadium salt solution, and stir for 15 minutes to form a mixed solution A;

[0023] Step 2: Take NaN 3 As nitrogen source, NaN 3 by NaN 3 : Bi(NO 3 ) 3 ·5H 2 The molar ratio of O=0.8 is added to the mixed solution A, and the mixed solution B is formed after stirring; the NH 4 Cl and N 2 h 4 ·H 2 O by NaN 3 : NH 4 Cl:N 2 h 4 ·H 2 The molar ratio of O=3:1:1 will NH 4 Cl and N 2 h 4 ·H 2 O was added to the mixed solution B, and magnetically stirred for 30 minutes to form a precursor;

[0024] Step 3: Put the precursor into the polytetrafluoroethylene reaction kettle, pass nitrogen into the reaction kettle for 3 minutes to discharge the air in the kettl...

Embodiment 2

[0027] Step 1: Add 0.01mol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20ml of deionized water, stirred for 30min to obtain a bismuth salt solution, and 0.01mol of NH 4 VO 3 Dissolve in 20ml of 80°C deionized water, heat and stir for 20 minutes to obtain a vanadium salt solution, mix the bismuth salt solution and vanadium salt solution, and stir for 15 minutes to form a mixed solution A;

[0028] Step 2: Take NaN 3 As nitrogen source, NaN 3by NaN 3 : Bi(NO 3 ) 3 ·5H 2 The molar ratio of O=0.9 is added to the mixed solution A, and the mixed solution B is formed after stirring; the NH 4 Cl and N 2 h 4 ·H 2 O by NaN 3 : NH 4 Cl:N 2 h 4 ·H 2 The molar ratio of O=3:1:1 will NH 4 Cl and N 2 h 4 ·H 2 O was added to the mixed solution B, and magnetically stirred for 30 minutes to form a precursor;

[0029] Step 3: Put the precursor into the polytetrafluoroethylene reaction kettle, pass nitrogen into the reaction kettle for 5 minutes to discharge the air in the kettle...

Embodiment 3

[0032] Step 1: Add 0.01mol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20ml of deionized water, stirred for 30min to obtain a bismuth salt solution, and 0.01mol of NH 4 VO 3 Dissolve in 20ml of 80°C deionized water, heat and stir for 20 minutes to obtain a vanadium salt solution, mix the bismuth salt solution and vanadium salt solution, and stir for 15 minutes to form a mixed solution A;

[0033] Step 2: Take NaN 3 As nitrogen source, NaN 3 by NaN 3 : Bi(NO 3 ) 3 ·5H 2 The molar ratio of O=1.0 is added to the mixed solution A, and the mixed solution B is formed after stirring; the NH 4 Cl and N 2 h 4 ·H 2 O by NaN 3 : NH 4 Cl:N 2 h 4 ·H 2 The molar ratio of O=3:1:1 will NH 4 Cl and N 2 h 4 ·H 2 O was added to the mixed solution B, and magnetically stirred for 30 minutes to form a precursor;

[0034] Step 3: Put the precursor into the polytetrafluoroethylene reaction kettle, pass nitrogen into the reaction kettle for 6 minutes to discharge the air in the kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com