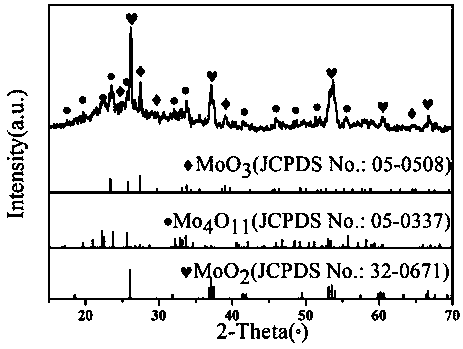

Three-phase system molybdenum oxide MoO3/Mo4O11/MoO2 nano electrode material and preparation method thereof

A technology of molybdenum oxide and three-phase system, which is applied in the direction of molybdenum oxide/molybdenum hydroxide, battery electrodes, circuits, etc., can solve the problems of nanometer electrode materials that have not been reported, and achieve high yield, environmental friendliness and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 1g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O), dissolved in a mixed solvent with a volume of 60 ml (volume ratio water: absolute ethanol = 11:1), stirred for 20 min, and then adjusted to pH = 1 with 3mol / L HCl while stirring to obtain a uniform solution A ;

[0030] (2) Pour the stirred solution A into a polytetrafluoroethylene-lined hydrothermal kettle, seal it, and then place it in a homogeneous reactor for solvothermal reaction at a temperature of 150°C for 15 hours;

[0031] (3) After the reaction, the reaction kettle was cooled at room temperature, and the product was alternately washed 6 times with deionized water and organic solvent absolute ethanol, and vacuum-dried to obtain product B;

[0032] (4) Weigh 0.5g of vacuum-dried product B, place it in a porcelain boat and heat-treat it in Ar. The heat-treatment temperature is 450°C, the time is 2h, and the heating rate is 10°C / min to obtain the target product MoO 3 / Mo 4 o 11 / Mo...

Embodiment 2

[0036] (1) Weigh 1g ammonium molybdate tetrahydrate ((NH4 ) 6 Mo 7 o 24 4H 2 O), dissolved in a mixed solvent with a volume of 60 ml (volume ratio water: absolute ethanol = 11:1), stirred for 20 min, and then adjusted to pH = 1 with 12mol / L HCl while stirring to obtain a uniform solution A ;

[0037] (2) Pour the stirred solution A into a polytetrafluoroethylene-lined hydrothermal kettle, seal it, and then place it in a homogeneous reactor for solvothermal reaction at a reaction temperature of 150°C for 24 hours;

[0038] (3) After the reaction, the reaction kettle was cooled at room temperature, and the product was alternately washed 6 times with deionized water and organic solvent absolute ethanol, and vacuum-dried to obtain product B;

[0039] (4) Weigh 0.5g of the vacuum-dried product B, put it in a porcelain boat and heat-treat it in Ar. The heat-treatment temperature is 300°C, the time is 4h, and the heating rate is 10°C / min to obtain the target product MoO 3 / Mo 4...

Embodiment 3

[0041] (1) Weigh 2g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O), dissolved in a mixed solvent with a volume of 60 ml (volume ratio water: absolute ethanol = 5:1), stirred for 20 min, and then adjusted to pH = 1 with 3mol / L HCl while stirring to obtain a uniform solution A ;

[0042] (2) Pour the stirred solution A into a polytetrafluoroethylene-lined hydrothermal kettle, seal it, and then place it in a homogeneous reactor for solvothermal reaction at a reaction temperature of 150°C for 6 hours;

[0043] (3) After the reaction, the reaction kettle was cooled at room temperature, and the product was alternately washed 6 times with deionized water and organic solvent acetone, and dried in vacuum to obtain product B;

[0044] (4) Weigh 0.5g of the vacuum-dried product B, put it in a porcelain boat and heat-treat it in Ar. The heat-treatment temperature is 500°C, the time is 2h, and the heating rate is 10°C / min to obtain the target product MoO 3 / Mo 4 o 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com