Durable antistatic finishing agent for fabrics and preparation method

An antistatic finishing agent and durability technology, which is applied in the field of fabric antistatic finishing agent and its preparation, can solve the problems of poor antistatic durability, antistatic agent not resistant to washing, etc., and achieve durable antistatic performance and firm combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

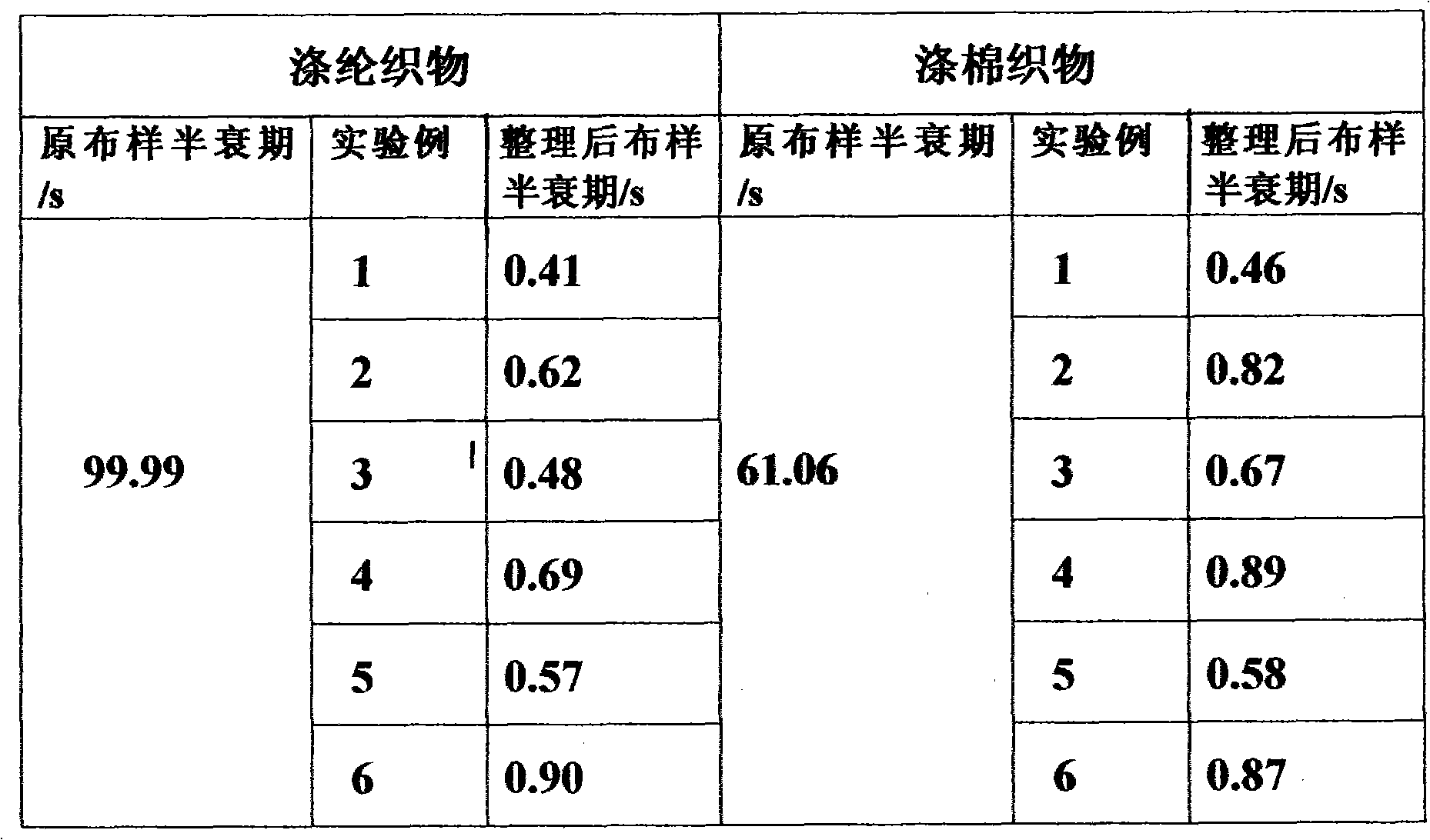

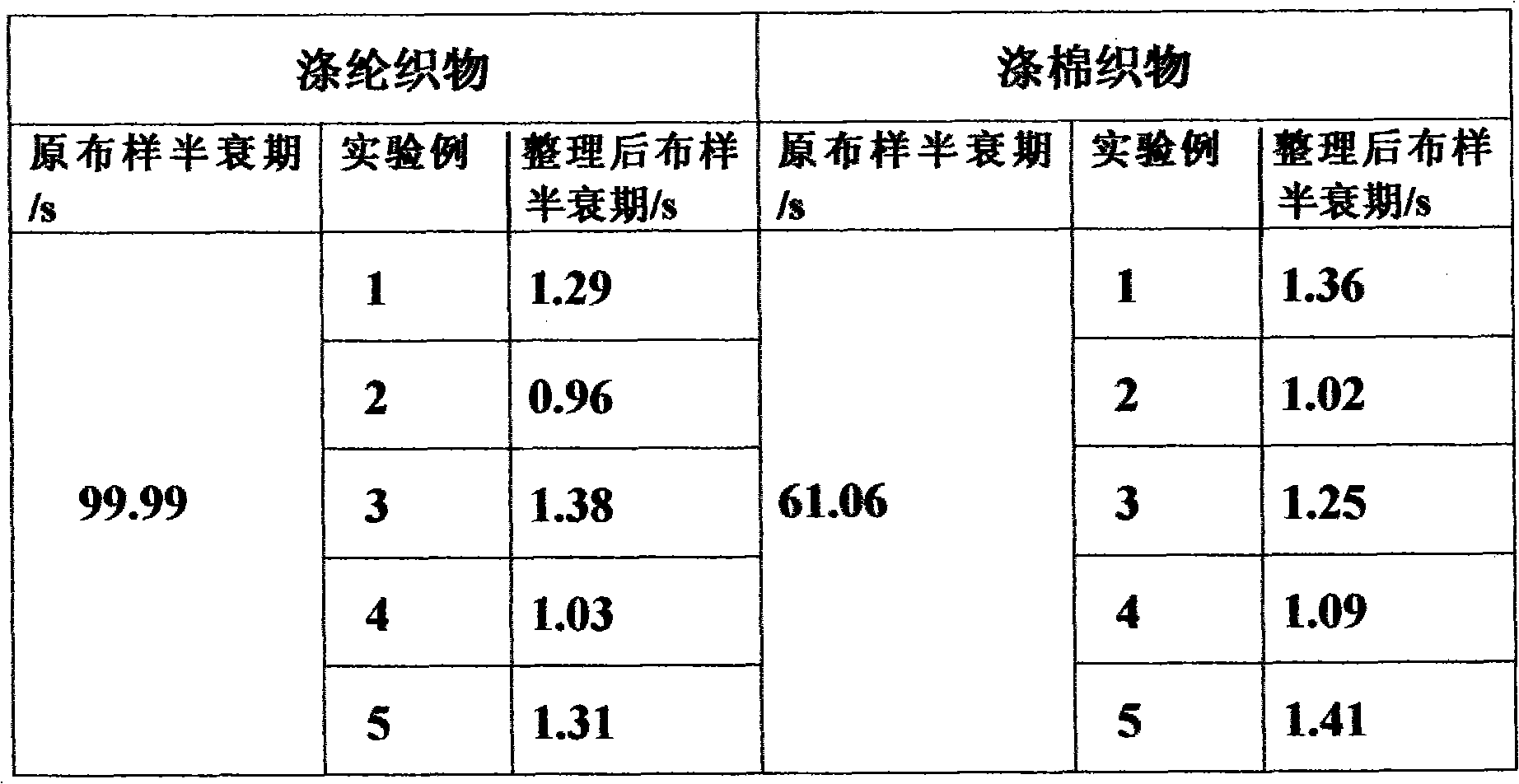

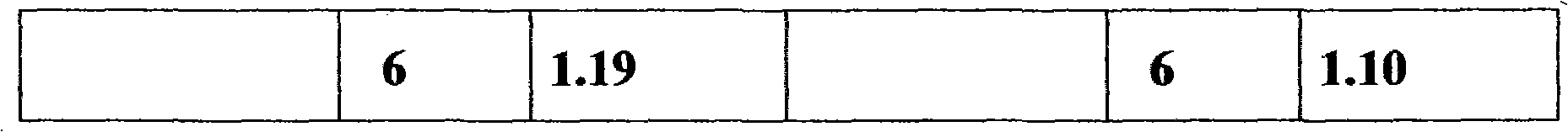

Examples

Embodiment 1

[0032] Add 100g of polyethylene glycol (hydroxyl value 56, dried), 32.8g of toluene diisocyanate (TDI), 9g of N-methyldiethanolamine, and 30g of acetone into a 1000ml four-port container equipped with a reflux condenser, a thermometer, and a stirrer in sequence. In the flask, pass through dry nitrogen protection, and react at a constant temperature of 75°C for 3 hours to prepare a polyurethane prepolymer, add 8g of glycerol glycidyl ether and 11g of acetone oxime, raise the temperature to 80°C, react for 3.5 hours, and cool down to 60°C. Add 11 g of dimethyl sulfate, react for 1 hour, then lower the temperature to below 40° C., add water and stir to obtain a reactive cationic polyurethane aqueous emulsion with a solid content of 25%.

Embodiment 2

[0034] Polyoxypropylene-oxyethylene glycol (hydroxyl value 56, dried) 100g, isophorone diisocyanate (IPDI) 41.8g, N-methyldiethanolamine 9g, methyl ethyl ketone 25g, sequentially add the tube, thermometer, and a 1000ml four-neck flask with a mixer, pass through dry nitrogen protection, and react at a constant temperature of 80°C for 3 hours to prepare a polyurethane prepolymer. ℃, react for 3.5 hours, cool down to 70°C, add 8g of dimethyl carbonate, react for 1.5 hours, then cool down to below 40°C, add water and stir to obtain a reactive cationic polyurethane aqueous emulsion with a solid content of 30%.

Embodiment 3

[0036] Hydroxy-terminated oxirane-tetrahydrofuran copolyether (hydroxyl value 75, dried) 110g, 1,6-hexamethylene diisocyanate (HDI) 43.7g, N-methyldiethanolamine 11.9g, dioxane 35g, Sequentially add to a 1000ml four-neck flask equipped with a reflux condenser, a thermometer, and a stirrer, pass through dry nitrogen protection, and react at a constant temperature of 70°C for 3 hours to prepare a polyurethane prepolymer. Add 20g of caprolactam and trimethylolpropane glycidyl ether 11g, heat up to 80°C, react for 3.5 hours, cool down to 60°C, add 16g of iodomethane, react for 2.0 hours, then cool down to below 40°C, add water and stir to obtain a reactive cationic polyurethane aqueous emulsion with a solid content of 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com