Poly(aryl etherketone) based varnish for wire coating and method coating a wire from a solution

A polyaryl ether ketone, metal wire technology, applied in the field of polyaryl ether ketone based varnish for metal wire coating and metal wire coating by solution, can solve unsatisfactory, can not provide low level defects Thin coating, etc., to achieve the effect of good adhesion, reduced dielectric failure, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

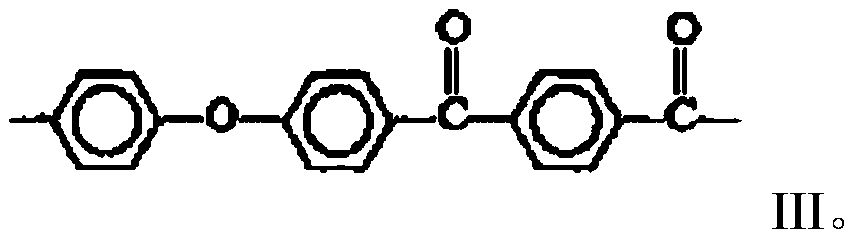

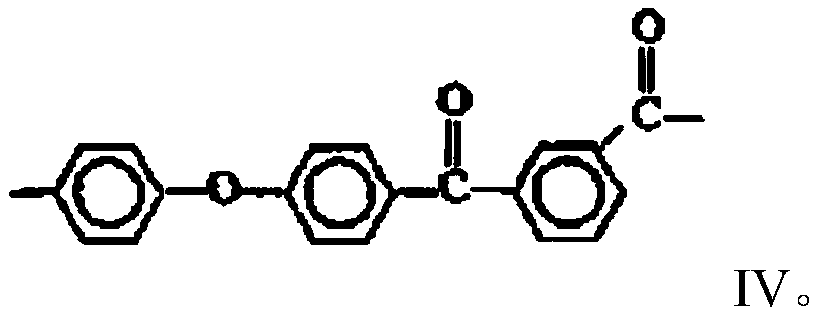

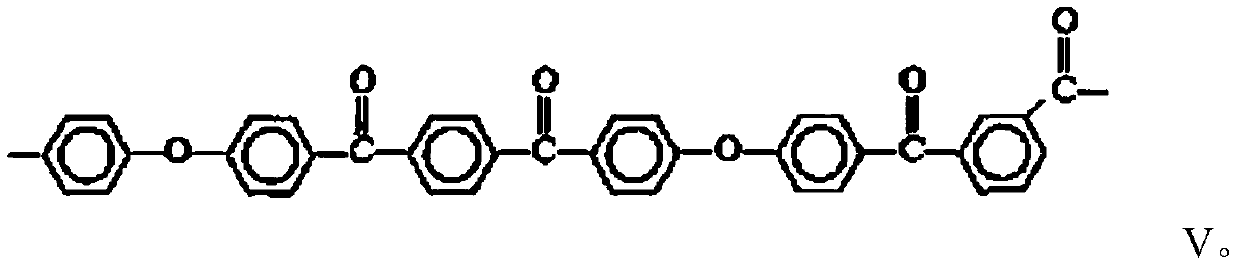

[0024] Aspects of the invention include: a coated metal wire having at least one polyarylketone-containing coating and a method of producing a coated metal wire from hydrogen, the varnish containing a polyaryl ketone dissolved in a phenolic solvent Ether ketones (such as polyether ketone ketone (PEKK) and polyether ether ketone (PEEK)).

[0025] As used herein, a "coating" is a thin layer, skin, or covering well known to those skilled in the art. Makes coatings adhere to electrical cables or wires. Depending on the application and use, the coating can be non-porous, porous, microporous, etc. The thickness of the coating is unlimited and can be any suitable thickness. For example, the coating thickness may range from about 1 nm (0.001 μm) to 1500 μm, such as from about 0.25 μm to about 250 μm. For some applications, the coating thickness can be from about 0.5 μm to about 2 μm. The total coating thickness (ie all coatings on the wire) of the coated metal wire obtained by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com