Preparation method of lithium iron phosphate with surface being uniformly coated by carbon

A technology with uniform surface of lithium iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems affecting electrochemical performance, limited conductive behavior of lithium iron phosphate, etc., to improve electrochemical performance and consistency Good, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The first step takes by weighing iron phosphate and lithium carbonate in the amount of 1:1 by lithium and iron molar ratio, takes by weighing sucrose by the amount of 10% of lithium iron phosphate quality;

[0023] In the second step, the mixture in the first step is placed in a high-energy ball mill tank, and 3 times the volume of ethanol is added to the above mixture, and ball milled for 5 hours;

[0024] In the third step, the mixture obtained in the second step is dried at 60° C. to obtain a precursor powder;

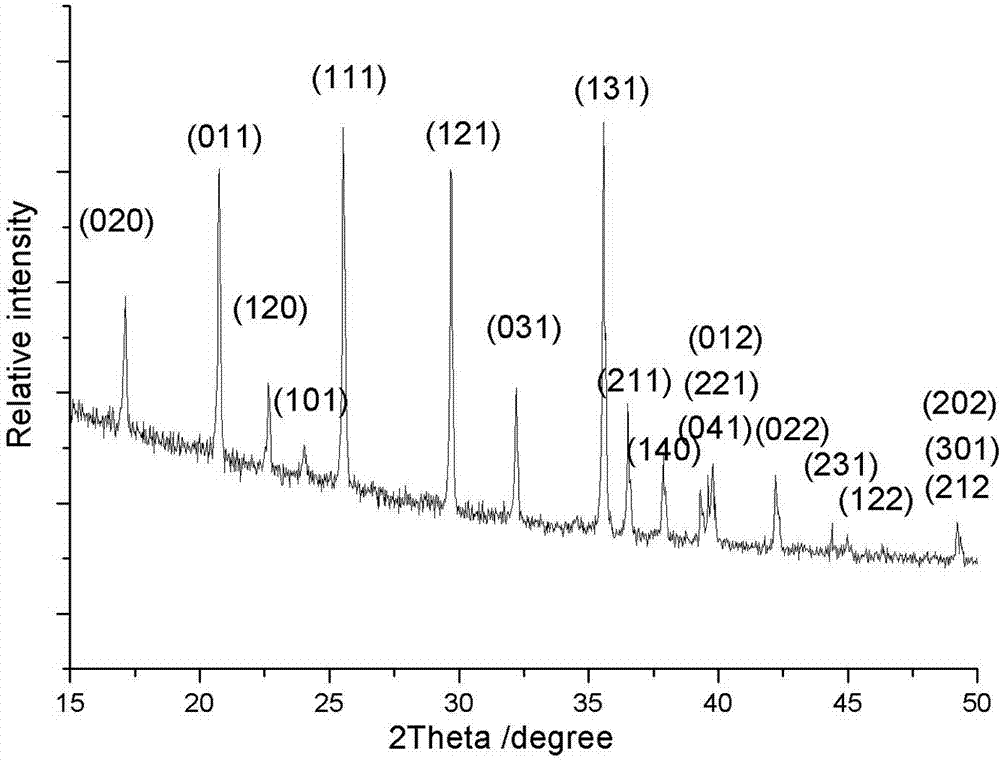

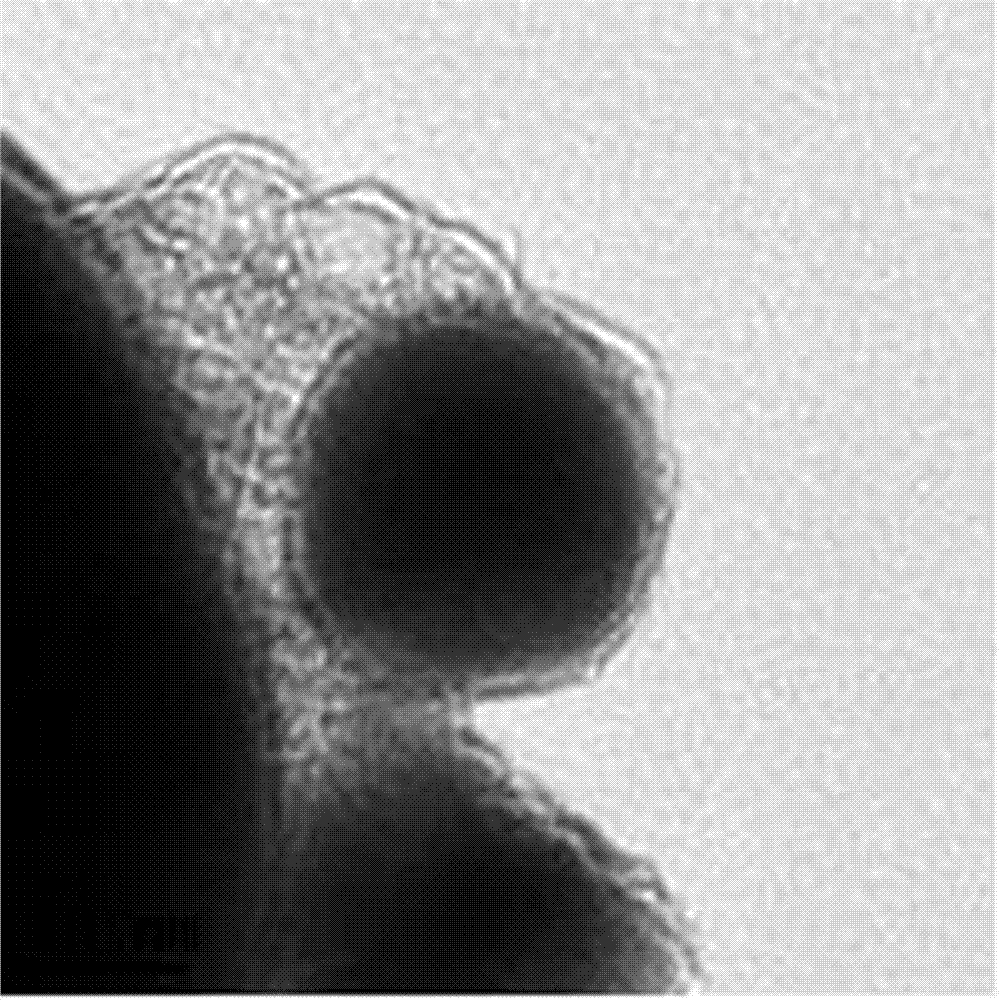

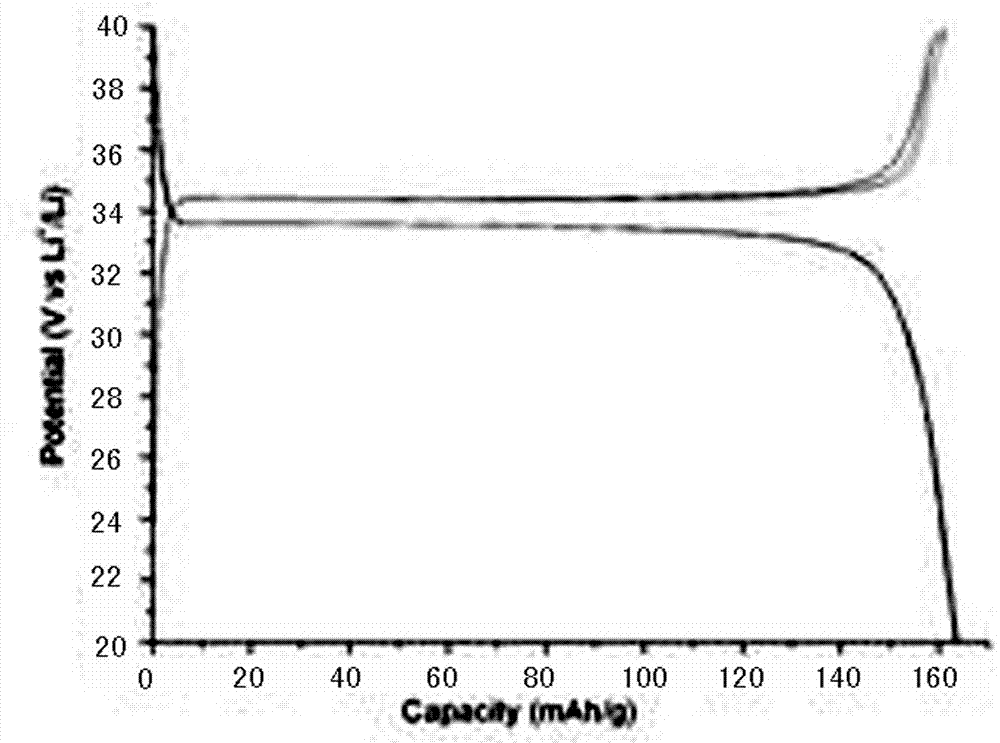

[0025] The fourth step is to place the precursor obtained in the third step in an atmosphere furnace. Under the protection of high-purity nitrogen, the heating rate of the entire heat treatment process is 5°C / min. First, it is raised from room temperature to 180°C and kept for 1 hour. Continue to raise the temperature to 750°C, keep it for 10 hours, and then lower it to room temperature to obtain a black substance, which is lithium iron phosphate whose partic...

Embodiment 2

[0027] The first step is to weigh iron phosphate and lithium carbonate in the amount of 1:1 by lithium and iron molar ratio, and take glucose in the amount of 10% of the lithium iron phosphate quality;

[0028] In the second step, place the mixture in the first step in a high-energy ball mill tank, add acetone of 3 times the volume of the above mixture, and ball mill for 5 hours;

[0029] In the third step, the mixture obtained in the second step is dried at 60° C. to obtain a precursor powder;

[0030] The fourth step is to place the precursor obtained in the third step in an atmosphere furnace. Under the protection of high-purity nitrogen, the heating rate of the entire heat treatment process is 5°C / min. First, it is raised from room temperature to 180°C and kept for 1 hour. Continue to raise the temperature to 750°C, keep it for 10 hours, and then lower it to room temperature to obtain a black substance, which is lithium iron phosphate whose particle surface is evenly coate...

Embodiment 3

[0032] The first step is to weigh iron phosphate and lithium carbonate in the amount of 1:1 by lithium and iron molar ratio, and take starch in the amount of 10% of the lithium iron phosphate quality;

[0033] In the second step, the mixture in the first step is placed in a high-energy ball mill tank, and 3 times the volume of ethanol is added to the above mixture, and ball milled for 5 hours;

[0034] In the third step, the mixture obtained in the second step is dried at 60° C. to obtain a precursor powder;

[0035] The fourth step is to place the precursor obtained in the third step in an atmosphere furnace. Under the protection of high-purity nitrogen, the heating rate of the entire heat treatment process is 5°C / min. First, it is raised from room temperature to 180°C and kept for 1 hour. Continue to raise the temperature to 750°C, keep it for 10 hours, and then lower it to room temperature to obtain a black substance, which is lithium iron phosphate whose particle surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com