A kind of slit die head for fluid coating of lithium ion battery

A lithium-ion battery, slit-type technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of battery slurry viscosity fluctuations, poor thickness uniformity of pole pieces, bubbles and exposed foil of pole pieces, etc., to achieve The flow rate and flow rate are effective and real-time, improving the coating consistency and eliminating the effect of residual air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below by specific embodiment, in conjunction with accompanying drawing, the technical solution of the present invention is described in further detail:

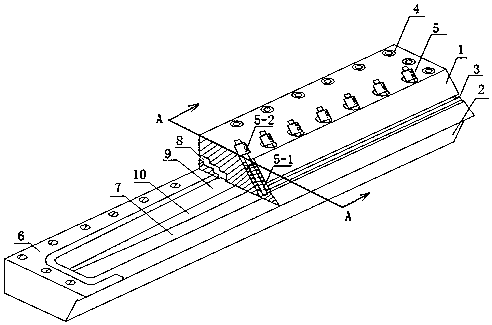

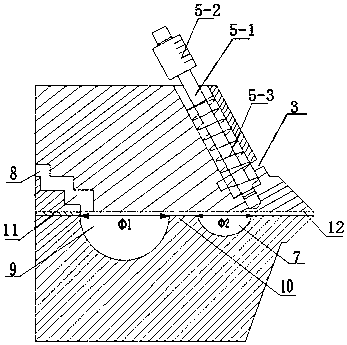

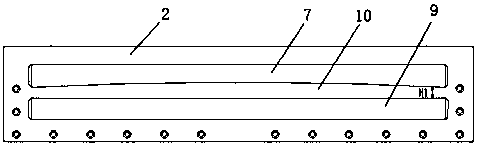

[0028] Such as figure 1 , 2 A kind of slit type die head for lithium-ion battery fluid coating shown, comprises upper die head, lower die head 2 and die head gasket 6 and is connected together by fastening bolt 4, and described upper die head 1, lower die head The gap between the front ends of the head 2 forms a slit outlet 12, the rear end of the upper die head 1 is provided with a feed port 8, and the front end top of the upper die head 1 is provided with a hole for adjusting the opening height of the slit outlet 12. fine-tuning screw rod 5; as image 3 As shown, the top surface of the lower die head 2 is provided with a liquid storage chamber 9 and a pressure stabilizing chamber 7 along its length direction, and the liquid storage chamber 9 and the pressure stabilizing chamber 7 are connected by a steady flow pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com