Coating method and coating machine for lithium battery negative electrode slurry

A technology of negative electrode slurry and coating method, which is applied in the directions of lithium battery, electrode collector coating, electrode manufacturing, etc., can solve the problem of the method of coating negative electrode slurry with high solid content, the solid content of negative electrode slurry Low energy consumption, high energy consumption, etc., to achieve normal coating, reduce energy consumption, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

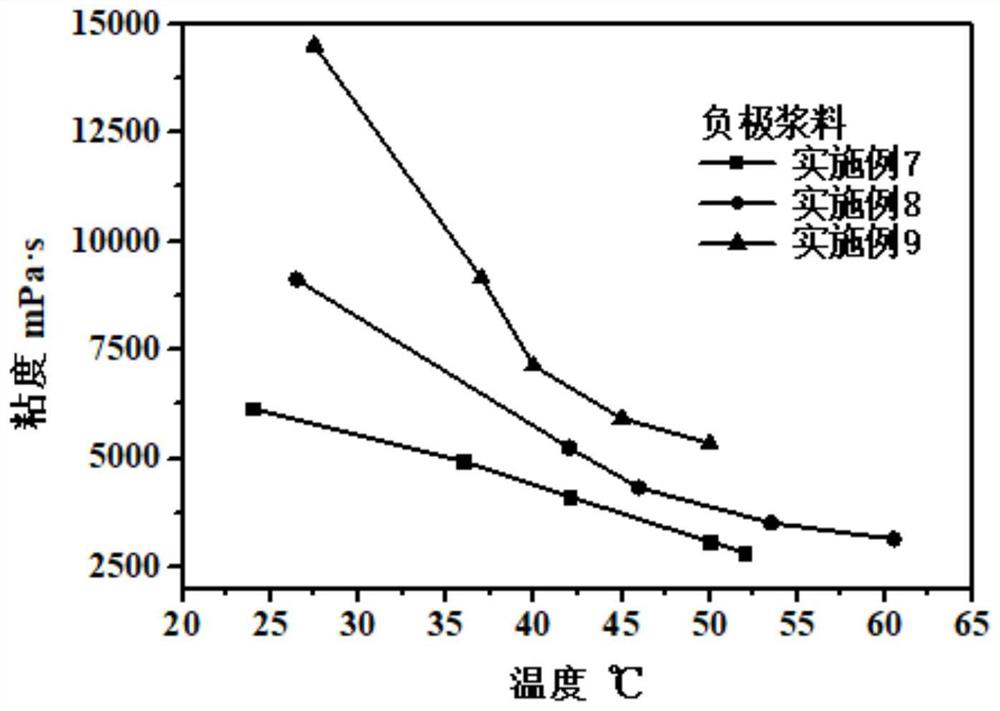

[0053] In the negative electrode slurry of this embodiment, the negative electrode active material is graphite, the thickener is CMC, the binder is SBR, the conductive agent is conductive carbon black SP, and the solvent is deionized water. The mass ratio of thickener and binder=96.3:0.9:1.0:1.8.

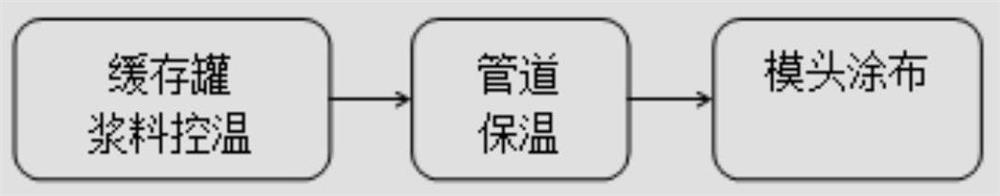

[0054] The coating method of the lithium battery negative electrode slurry comprises the following steps:

[0055] (1) Discharge the negative electrode slurry with a solid content of 55% and a viscosity of 8000cP, and then reach the buffer tank of the coating machine through pipelines and transfer tanks. The temperature of the negative electrode slurry during discharge is 25°C;

[0056] (2) The buffer tank of the coater controls the temperature of the negative electrode slurry to 45° C. to obtain a negative electrode slurry with a viscosity of 3950 cP;

[0057] (3) The negative electrode slurry with a viscosity of 3950cP in step (2) is transported to the die head of the coating mac...

Embodiment 2

[0060] The difference between this embodiment and Example 1 is that the solid content of the negative electrode slurry in step (1) is 58%, the viscosity is 13500cP, the viscosity of the negative electrode slurry after temperature control in step (2) is 5650cP, other parameters and conditions Exactly the same as in Example 1.

[0061] In this embodiment, after the temperature of the negative electrode slurry is controlled to 45° C., the viscosity of the negative electrode slurry drops to a viscosity suitable for coating by the die head of a coating machine, thereby achieving normal coating of the high solid content negative electrode slurry.

Embodiment 3

[0063] The difference between this embodiment and Example 1 is that the solid content of the negative electrode slurry in step (1) is 52%, the viscosity is 6500cP, the viscosity of the negative electrode slurry after temperature control in step (2) is 4360cP, other parameters and conditions Exactly the same as in Example 1.

[0064] In this embodiment, after the temperature of the negative electrode slurry is controlled to 45° C., the viscosity of the negative electrode slurry drops to a viscosity suitable for coating by the die head of a coating machine, thereby achieving normal coating of the high solid content negative electrode slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com