Security lithium ion battery positive plate as well as preparation method thereof

A technology of lithium-ion batteries and positive plates, which is applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of poor safety performance of high specific energy power lithium-ion batteries, and achieve improved long-term cycle performance and good absorption and retention ability, and the effect of improving the long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

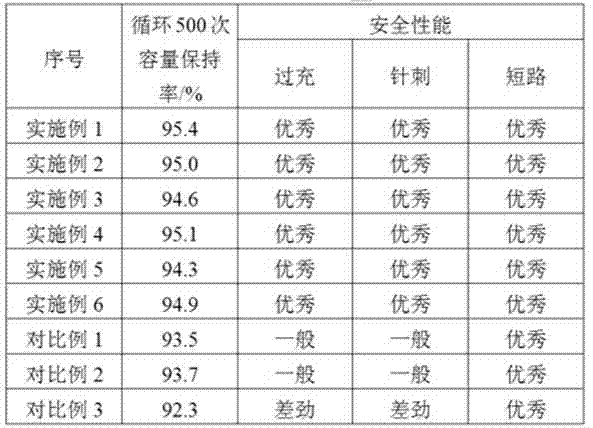

Examples

Embodiment 1

[0029] Nickel-cobalt-manganese ternary material Li(Ni 1 / 3 CO 1 / 3 mn 1 / 3 )O 2 , lithium manganese phosphate LiMnPO 4 and ceramic material Al 2 o 3 or SiO 2 The mass ratio is 82%: 15%: 3%.

[0030] lithium manganese phosphate LiMnPO 4 , Binder SBR+CMC, and conductive agent are mixed together at a ratio of 92%:4%:4%, and deionized water is used as the dispersion medium, and a slurry of a certain viscosity is prepared by high-speed stirring, and coated on the 18um thick positive electrode A first coating is formed on the current collector aluminum foil. Then the nickel-cobalt-manganese ternary material Li(Ni 1 / 3 CO 1 / 3 mn 1 / 3 )O 2 , the binder PVDF and the conductive agent are mixed together at a ratio of 92%: 4%: 4%, and N-methylpyrrolidone NMP is used as the dispersion medium, and a slurry of a certain viscosity is prepared by high-speed stirring, and coated on the first On top of the coating, a second coating is formed. Finally, the ceramic material Al 2 o 3 , S...

Embodiment 2

[0033] Nickel-cobalt-manganese ternary material Li(Ni 0.4 CO 0.2 mn 0.4 )O 2 , lithium manganese phosphate LiMnPO 4 and ceramic material Al 2 o 3 +SiO2 2 The mass ratio is 82%: 15%: 3%.

[0034] First, lithium manganese phosphate LiMnPO4, binder SBR+CMC, and conductive agent are mixed together at a ratio of 92%:4%:4%, and deionized water is used as the dispersion medium to prepare a slurry with a certain viscosity by high-speed stirring. Coating on 18um thick positive electrode current collector aluminum foil to form the first coating. Then the nickel-cobalt-manganese ternary material Li(Ni 0.4 CO 0.2 mn 0.4 )O 2 , the binder PVDF and the conductive agent are mixed together at a ratio of 92%: 4%: 4%, and N-methylpyrrolidone NMP is used as the dispersion medium, and a slurry of a certain viscosity is prepared by high-speed stirring, and coated on the first On top of the coating, a second coating is formed. Finally, the ceramic material Al 2 o 3 , SiO2, and binder...

Embodiment 3

[0037] Nickel-cobalt-manganese ternary material Li(Ni 0.5 CO 0.2 mn 0.3 )O 2 , lithium manganese phosphate LiMnPO 4 and ceramic material Al 2 o 3 +SiO2 2 The mass ratio is 75%:20%:5%.

[0038] lithium manganese phosphate LiMnPO 4 , Binder SBR+CMC, and conductive agent are mixed together at a ratio of 92%:4%:4%, and deionized water is used as the dispersion medium, and a slurry of a certain viscosity is prepared by high-speed stirring, and coated on the 18um thick positive electrode A first coating is formed on the current collector aluminum foil. Then the nickel-cobalt-manganese ternary material Li(Ni 0.5 CO 0.2 mn 0.3 )O 2 , the binder PVDF and the conductive agent are mixed together at a ratio of 92%: 4%: 4%, and N-methylpyrrolidone NMP is used as the dispersion medium, and a slurry of a certain viscosity is prepared by high-speed stirring, and coated on the first On top of the coating, a second coating is formed. Finally, the ceramic material Al 2 o 3 , SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com