A kind of ruthenium series ammonia synthesis catalyst and its preparation method and application

A technology of ammonia synthesis and catalyst, applied in the field of ruthenium ammonia synthesis catalyst and its preparation, can solve the problems of poor stability and low catalytic performance, achieve the effects of preventing agglomeration, improving catalytic activity and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

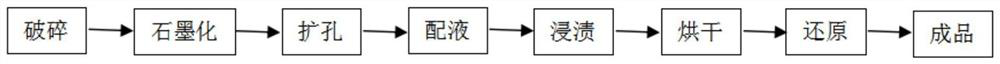

[0054] The present embodiment provides a kind of ruthenium series ammonia synthesis catalyst, and its preparation method is as follows:

[0055] The preparation method of graphitized activated carbon: Take 20g of activated carbon and crush it to 15-20 mesh, put it in an intermediate frequency furnace, treat it in an argon atmosphere at 1800 ° C for 2 hours, cool it to room temperature in the above atmosphere, and use air oxidation at 400 ° C to expand the pores , that is graphitized activated carbon, the specific surface area of the graphitized activated carbon is 800m 2 / g, the pore volume is 0.5cm 3 / g.

[0056] Preparation of mixed solution: add ruthenium nitrosonitrate, barium nitrate, cerium nitrate, and potassium nitrate into deionized water in a ratio of 2:3:1:3 with the mass ratio of ruthenium, barium, cerium, and potassium, and stir evenly. The pH of the solution was adjusted to 1 with nitric acid.

[0057] Catalyst preparation: Take 10 g of the above-mentioned g...

Embodiment 2

[0061] The present embodiment provides a kind of ruthenium series ammonia synthesis catalyst, and its preparation method is as follows:

[0062] The preparation method of graphitized activated carbon: Take 20g of activated carbon and crush it to 15-20 mesh, put it in an intermediate frequency furnace, treat it in an argon atmosphere at 1800 ° C for 2 hours, cool it to room temperature in the above atmosphere, and use air oxidation at 400 ° C to expand the pores , that is graphitized activated carbon, the specific surface area of the graphitized activated carbon is 800m 2 / g, the pore volume is 0.5cm 3 / g.

[0063] Preparation of mixed solution: add ruthenium nitrosonitrate, barium nitrate, cerium nitrate, and potassium nitrate into deionized water in a ratio of 2:3:1:3 with the mass ratio of ruthenium, barium, cerium, and potassium, and stir evenly. The pH of the solution was adjusted to 2 with acetic acid.

[0064] Catalyst preparation: Take 10 g of the above-mentioned g...

Embodiment 3

[0068] The present embodiment provides a kind of ruthenium series ammonia synthesis catalyst, and its preparation method is as follows:

[0069] The preparation method of graphitized activated carbon: Take 20g of activated carbon and crush it to 15-20 mesh, put it in an intermediate frequency furnace, treat it in an argon atmosphere at 1800 ° C for 2 hours, cool it to room temperature in the above atmosphere, and use air oxidation at 400 ° C to expand the pores , that is graphitized activated carbon, the specific surface area of the graphitized activated carbon is 800m 2 / g, the pore volume is 0.5cm 3 / g.

[0070] Preparation of mixed solution: add ruthenium nitrosonitrate, barium nitrate, cerium nitrate, and potassium nitrate into deionized water in a ratio of 3:6:2:6 in a mass ratio of ruthenium, barium, cerium, and potassium, and stir evenly. The pH of the solution was adjusted to 1 with nitric acid.

[0071] Catalyst preparation: take 10 g of the above-mentioned graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com