MoS<x>/carbon black nanometer composite material and preparation method and application thereof

A technology of nano-composite materials and carbon black, applied in the field of composite materials, can solve the problems of complex preparation methods and gaps in catalytic performance, and achieve the effects of increasing catalytic performance, improving performance and enhancing electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the aforementioned nanocomposite material, wherein the method includes the following steps:

[0037] (1) Disperse carbon black in water, preferably ultrasonically for 10-30 minutes, to obtain a carbon black dispersion;

[0038] In a specific embodiment of the present invention, the ratio of carbon black to water is preferably 1-16 mg:1 mL, and the carbon black is selected from at least one of acetylene black, Cabot carbon black, and Ketjen black, preferably It is at least one of Cabot Black XC-72, Cabot Black XC-72R or Cabot Black BP-2000. The higher the conductivity of these carbon blacks, the prepared MoS x / Carbon black nanocomposite material has better conductivity. During specific implementation, the ultrasonic power can be 500-1200W.

[0039] (2) The sulfur source and the molybdenum source are added to the carbon black dispersion to obtain a mixed solution;

[0040] In the specific implementation process, the sul...

Embodiment 1

[0051] Example 1: MoS x / Preparation and Application of Carbon Black Nanocomposite

[0052] Prepare MoS x / Carbon black nanocomposite

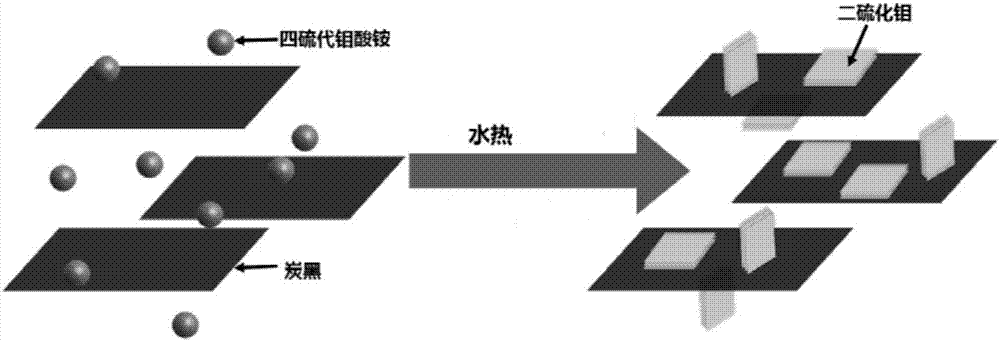

[0053] Disperse 200mg of acetylene black into 50ml of deionized water (4mg / mL), and use an ultrasonic processor to ultrasonically disperse for 10 minutes at room temperature (ultrasonic power of 650W) to obtain an acetylene black dispersion; subsequently, add 200mg of ammonium tetrathiomolybdate, The mixed solution is obtained; the mixed solution is transferred to a 100ml polytetrafluoroethylene-lined hydrothermal kettle, and then sent to a preheated 220°C blast oven to react for 24 hours. After the reaction is completed, the oven is closed and allowed to cool naturally. Filter and wash with deionized water; dry the washed product in a vacuum oven at 40°C for 12 hours to obtain powdered MoS x / Carbon black nanocomposite materials. The preparation process and principle are as figure 1 Shown.

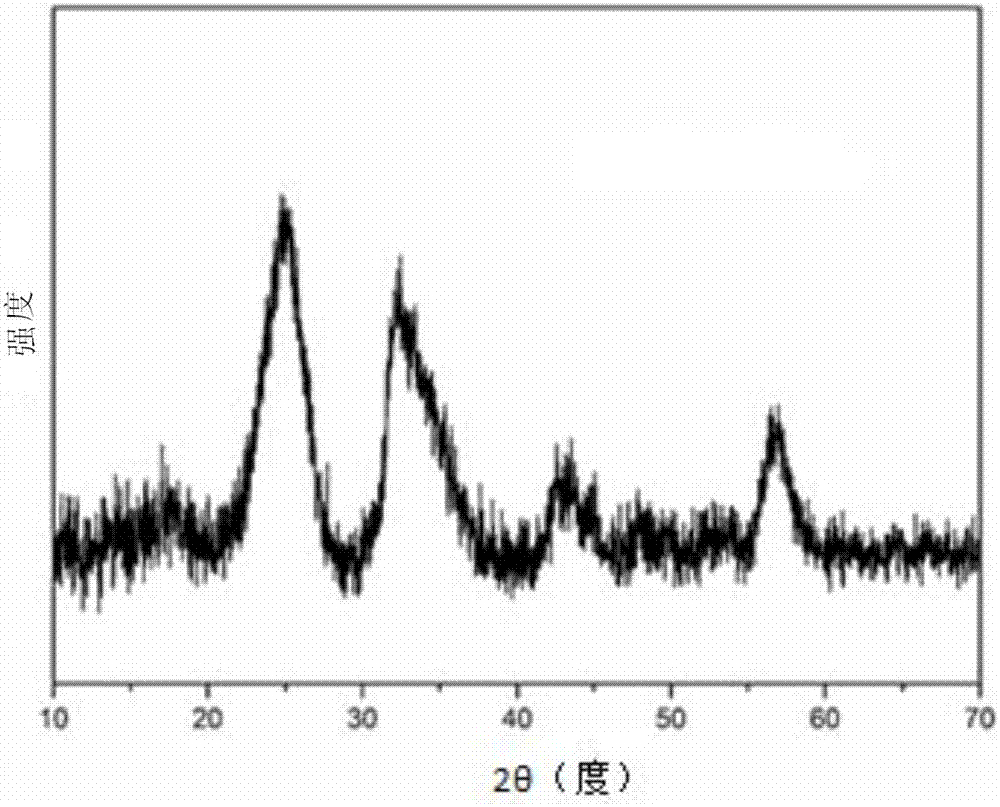

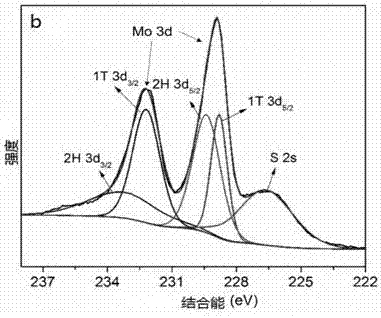

[0054] For the prepared MoS x / Carbon black nanocomposi...

Embodiment 2

[0065] Example 2: MoS x / C Preparation of Nanocomposites

[0066] The acetylene black in Example 1 was changed to Cabot Black XC-72, and the other preparation conditions of the composite material were the same as in Example 1. MoS was prepared under these conditions x / Carbon black nanocomposite, MoS x The mass percentage of 1T is about 25%, the content of 1T is about 50%, and the atomic ratio of Mo and S is 1:2.11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com