A kind of water-based zinc-ion battery cathode material and matching electrolyte

A technology of zinc ion battery and cathode material, applied in battery electrodes, aqueous electrolytes, secondary batteries, etc., can solve the problems of increasing process complexity and cost, difficulty in large-scale preparation, increasing active sites, etc., so as to increase reaction activity site, easy to scale up, enhanced effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh potassium permanganate and manganese acetate tetrahydrate, grind and mix evenly at a molar ratio of 1:1, transfer the ground mixture to a crucible; place the crucible in a tube furnace and heat up at 5°C / min Heat at a rate of 150°C and keep it warm for 4 hours, then heat it up to 400°C at a heating rate of 5°C / min, keep it warm for 1 hour, wait until the tube furnace cools down to room temperature, and collect the product; the obtained product is washed with deionized water, filtered with suction times, and then dried in an oven at 80°C to obtain K 0.1 MnO 2-yCathode material.

Embodiment 2

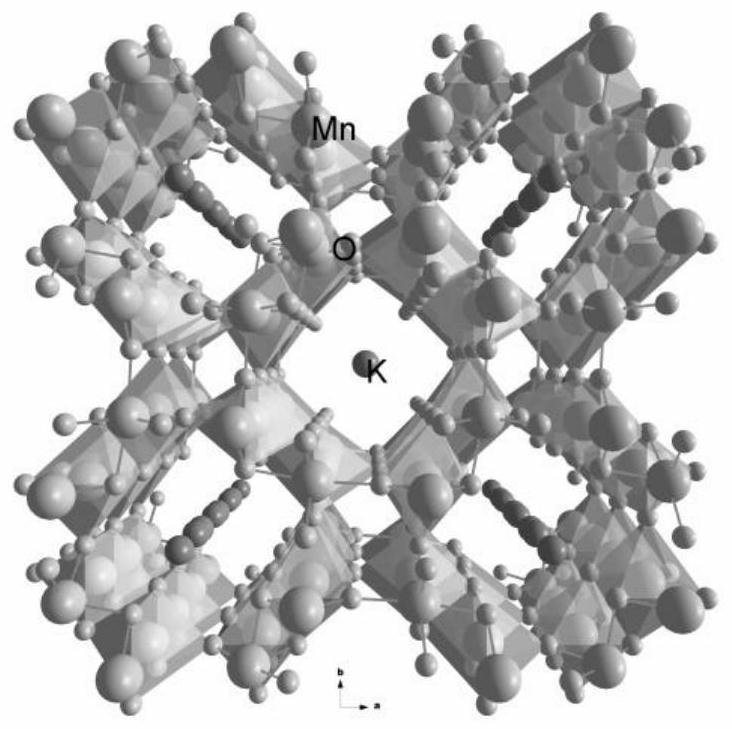

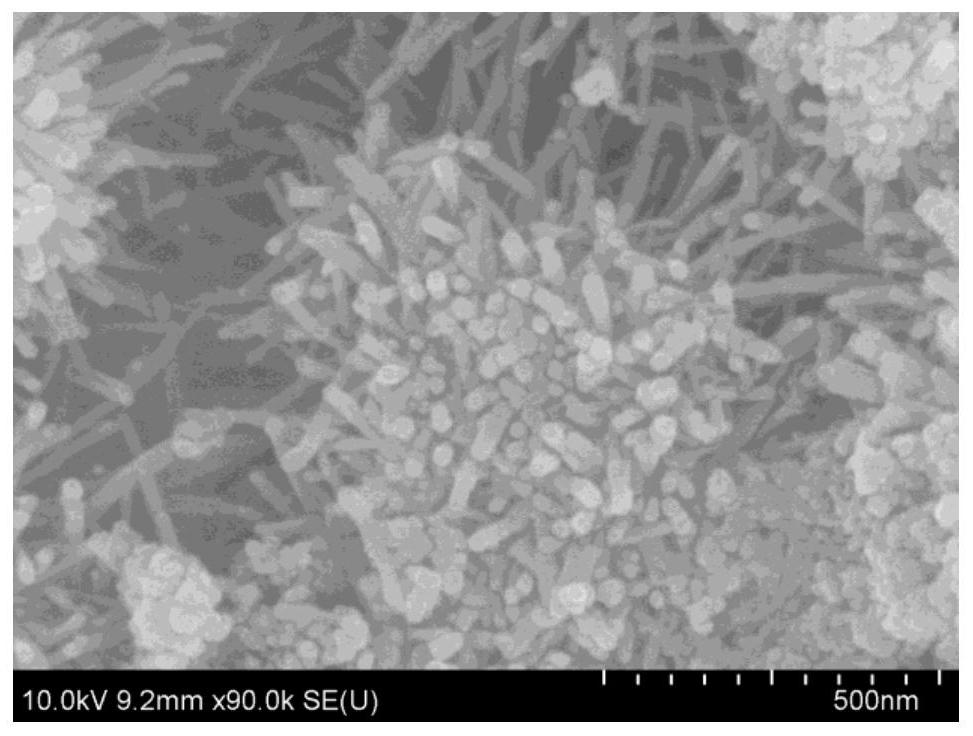

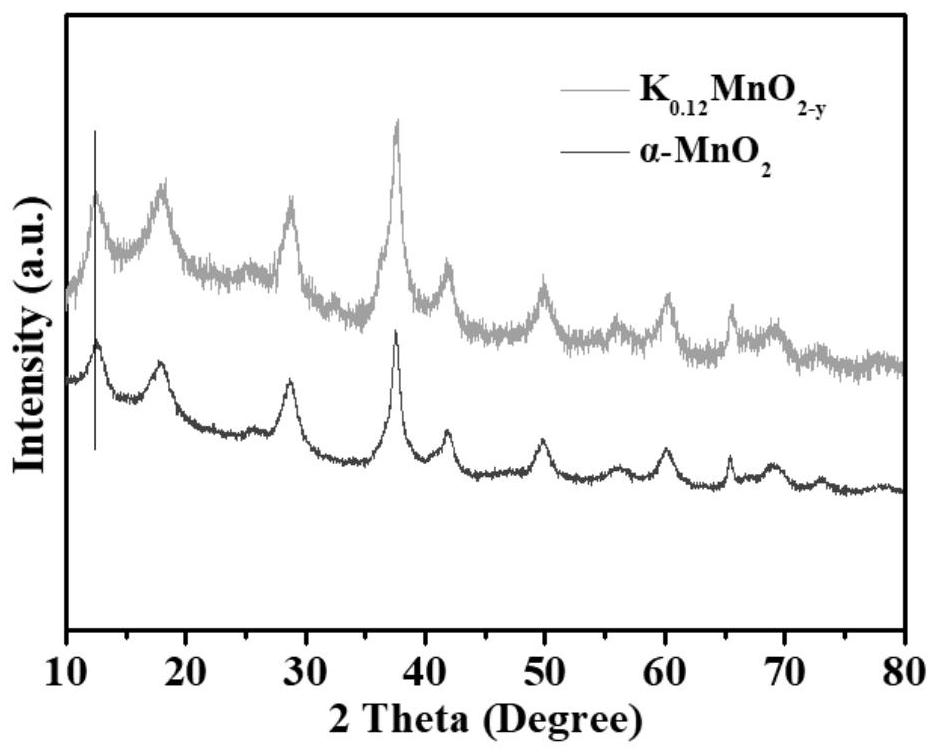

[0038] Weigh potassium permanganate and manganese acetate tetrahydrate, grind and mix evenly at a molar ratio of 1:1.5, transfer the ground mixture to a crucible; place the crucible in a tube furnace and heat up at 5°C / min under an argon atmosphere Heat at a rate of 180°C and keep it warm for 4h, then heat it up to 500°C at a rate of 5°C / min and keep it warm for 2h, wait until the tube furnace cools down to room temperature, collect the product; wash the obtained product with deionized water, filter with suction times, and then dried in an oven at 80°C to obtain K 0.12 MnO 2-y Cathode material. K 0.12 MnO 2-y The schematic diagram of the crystal structure of the cathode material is shown in figure 1 , K + Located in the tunnel structure of manganese dioxide; SEM see figure 2 , the cathode material presents a nanorod-like morphology; the XRD pattern is shown in image 3 , compared with pristine manganese dioxide, the low-angle diffraction peak of the cathode material is...

Embodiment 3

[0041] Weigh potassium permanganate and manganese acetate tetrahydrate, grind and mix evenly at a molar ratio of 1:1.5, transfer the ground mixture to a crucible; place the crucible in a tube furnace and heat up at 5°C / min under an argon atmosphere Heat at a rate of 180°C and keep it warm for 4h, then heat it up to 600°C at a rate of 5°C / min and keep it warm for 2h, wait until the tube furnace cools down to room temperature, and collect the product; the obtained product is washed with deionized water, filtered with suction times, and then dried in an oven at 80°C to obtain K 0.12 MnO 2-y Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com