A kind of graphite negative electrode material and its preparation method and application

A technology of graphite anode and graphite particles, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of low specific capacity, inability to meet high-capacity and high-power lithium-ion batteries, etc., and achieve improved conductivity, good rate and Cyclic performance, effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The present embodiment is a preparation method of a graphite negative electrode material, comprising the following steps:

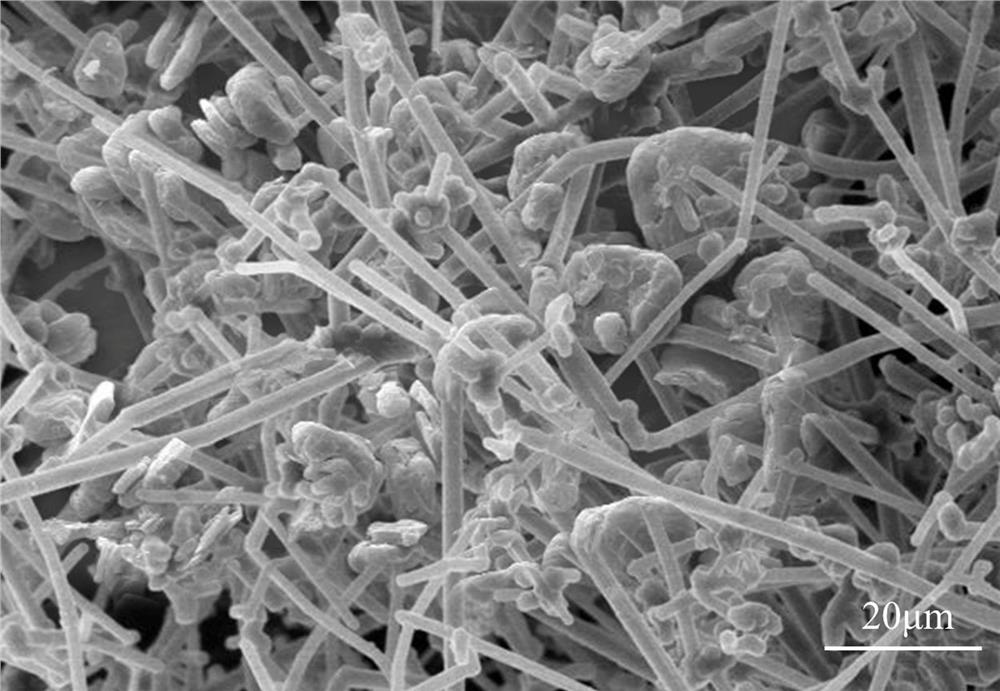

[0085] S1. Add 10g carbon fiber (Beijing Merida Technology Co., Ltd., carbon nanofiber, diameter: 150nm~200nm; length: 10μm~30μm) to 100mL 0.1mol / L amino coupling agent (KH550) solution, at 110°C After reacting for 2 hours, the solid-liquid separation was performed, and the amino-modified carbon fiber was obtained after freeze-drying;

[0086] 10g of the first particle graphite ((Shanghai Macklin Biochemical Technology Co., Ltd., article number: G810739, 750 mesh to 850 mesh (about 18μm))) and 10g of the second particle graphite (Shanghai Macklin Biochemical Technology Co., Ltd., article number: G810365 , 8000 mesh (1.6μm)) were added to 100mL oxidant solution (sodium persulfate solution with a mass fraction of 5%), oxidized at 65°C for 20h, and freeze-dried after solid-liquid separation to obtain the first graphite oxide particles and a second pa...

Embodiment 2

[0103] This embodiment is a method for preparing a graphite negative electrode material, and the difference from Embodiment 1 is that the mass of the second particle graphite in this embodiment is 20 g.

Embodiment 3

[0105] This example is a method for preparing a graphite negative electrode material, and the difference from Example 1 is that the mass percentage of sodium persulfate in this example is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com