Application of titanium boride for chemically trapping polysulfides in lithium-sulfur batteries to prepare cathode materials for lithium-sulfur batteries

A lithium-sulfur battery and polysulfide technology, applied in the direction of battery electrodes, boron/boride, metal boride, etc., to achieve the effects of improving utilization, inhibiting shuttle effect, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

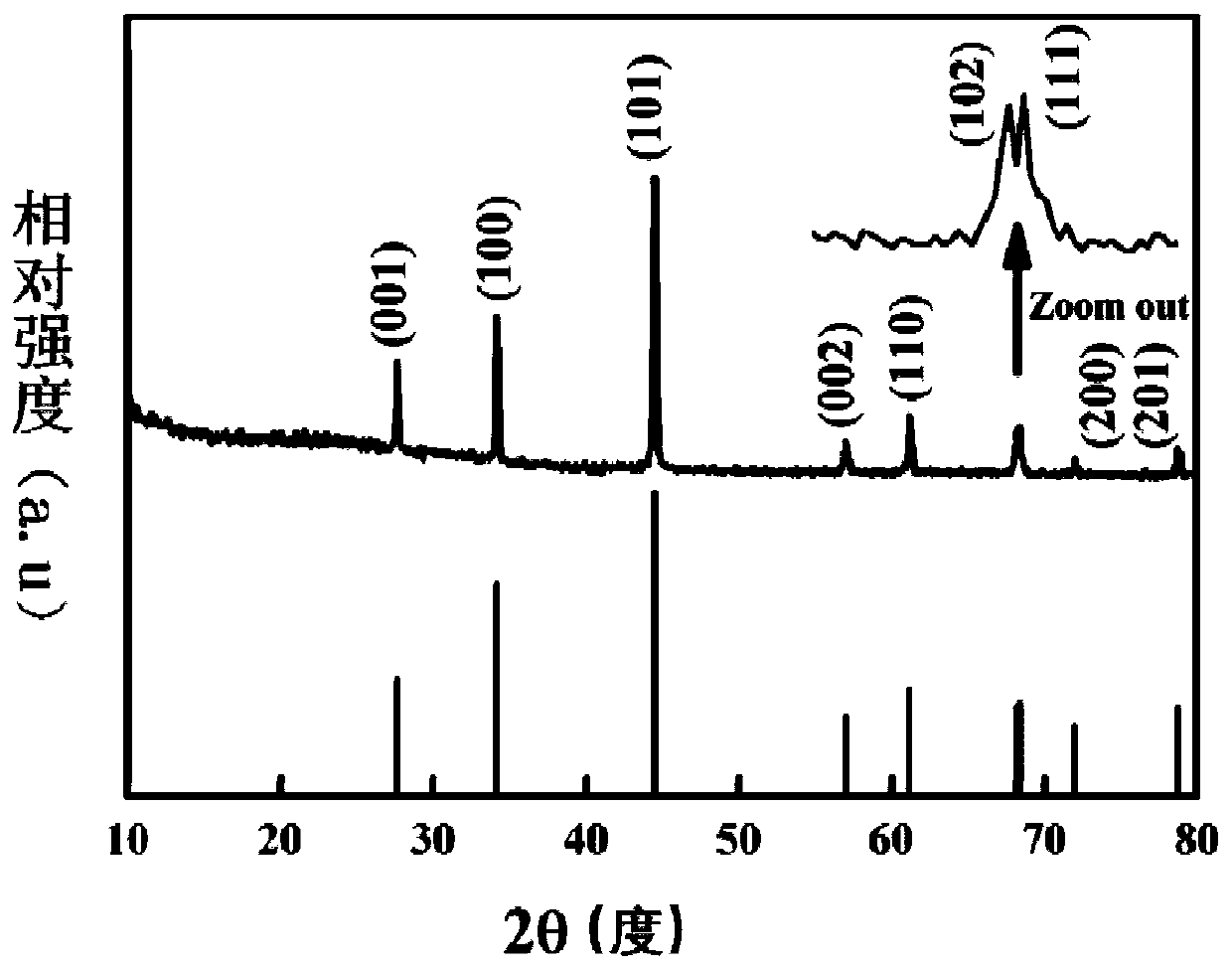

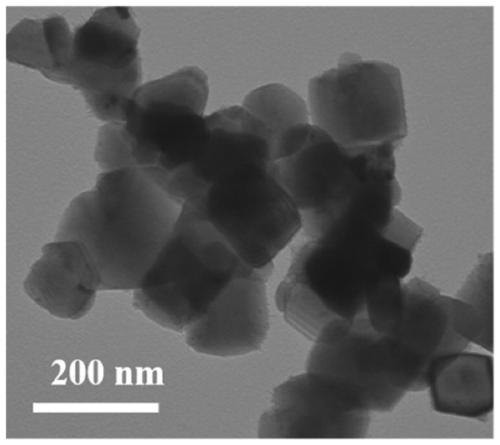

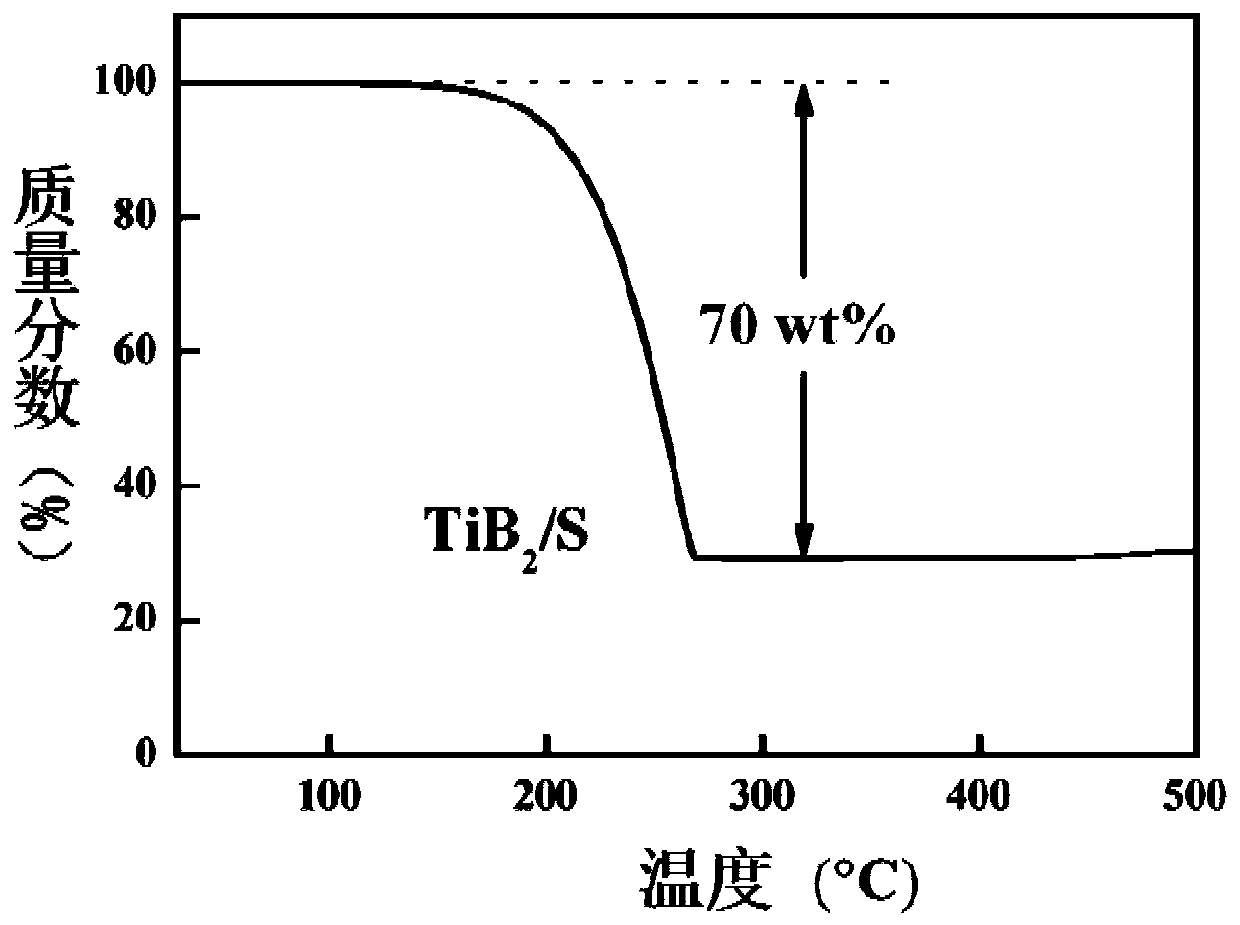

[0044] A titanium boride used for chemically trapping polysulfides in lithium-sulfur batteries, the microscopic appearance of the titanium boride is nanoparticles with a particle size of about 200nm; the titanium boride is a hexagonal crystal phase, and boron atoms are inserted into the A hexagonal structure is formed in the gaps between titanium atomic layers.

[0045] The above-mentioned preparation method of titanium boride used for chemically trapping polysulfides in lithium-sulfur batteries comprises the following steps:

[0046] Hand-grind 1.2g of titanium dioxide, 4.32g of magnesium powder, and 0.3g of boron powder with a mortar for 0.5h, mix them evenly, add them into a stainless steel iron kettle, then add 2.7mL of deionized water, seal it, and put it in an oven at 150°C Thermal reaction for two hours; the reacted product was stirred with 1mol / L hydrochloric acid for 12 hours, then suction filtered, washed with deionized water and ethanol three times respectively to r...

Embodiment 2

[0059] A preparation method of titanium boride used for chemically trapping polysulfides in lithium-sulfur batteries, the preparation steps are as described in Example 1, the difference is that the hydrothermal reaction time is 4 hours, and the others are consistent with Example 1.

[0060] The application of the above-mentioned titanium boride to prepare the positive electrode material of lithium-sulfur battery, the preparation method is as described in Example 1.

Embodiment 3

[0062] A preparation method for titanium boride used in lithium-sulfur batteries to chemically trap polysulfides, the preparation steps are as described in Example 1, the difference is that the amounts of titanium dioxide, magnesium powder, boron powder, and deionized water are respectively 1.36g , 4.9g, 0.34g, 3.06mL, others are consistent with Example 1.

[0063] The application of the above-mentioned titanium boride to prepare the positive electrode material of lithium-sulfur battery, the preparation method is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com