Water system high-voltage mixed ion secondary battery based on zinc-lithium ferric manganese phosphate

A mixed ion and secondary battery technology, which is applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of fast decay of capacitance, low capacitance of negative electrode materials, and easy to be affected by oxygen and water, etc., to achieve excellent The effects of rate performance, high capacity, and rechargeable capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

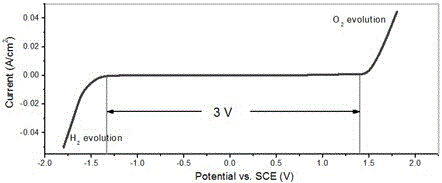

[0024] With 21mol / L LiTFSI and 0.5mol / L ZnSO 4The aqueous solution of the electrolyte is used as the electrolyte, and the pH value of the electrolyte is controlled at 7 by adding an appropriate amount of lithium hydroxide (LiOH). The potential window of the electrolyte is as follows figure 1 shown.

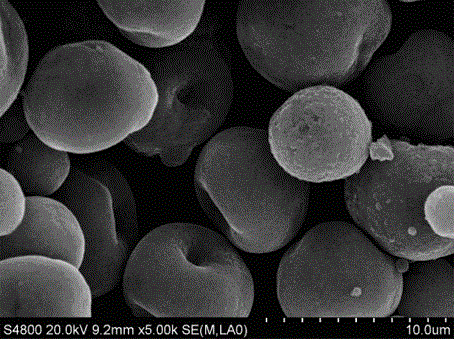

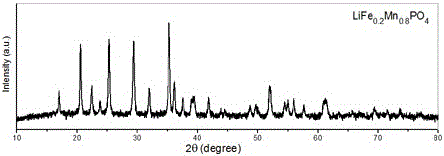

[0025] Commercially available lithium manganese iron phosphate (LiFe 0.2 mn 0.8 PO 4 ) as the cathode active material, LiFe 0.2 mn 0.8 PO 4 SEM pictures and XRD spectra such as figure 2 with image 3 shown. LiFe 0.2 mn 0.8 PO 4 , the conductive agent acetylene black and the binder polytetrafluoroethylene are mixed in a mass ratio of 7:2:1, coated on the surface of the current collector graphite film, cut into a certain size, and dried in a vacuum to obtain LiFe 0.2 mn 0.8 PO 4 electrode sheet.

[0026] LiFe 0.2 mn 0.8 PO 4 The electrode sheet is the positive electrode, the zinc sheet with a thickness of 0.15mm is the negative electrode, LiTFSI and ZnSO 4 The mi...

Embodiment 2

[0028] Commercially available lithium manganese iron phosphate (LiFe 0.3 mn 0.7 PO 4 ) is the positive electrode active material. LiFe 0.3 mn 0.7 PO 4 , the conductive agent acetylene black and the binder polytetrafluoroethylene are mixed in a mass ratio of 7:2:1, coated on the surface of the current collector graphite film, cut into a certain size, and dried in a vacuum to obtain LiFe 0.3 mn 0.7 PO 4 electrode sheet.

[0029] LiFe 0.3 mn 0.7 PO 4 The electrode sheet is the positive electrode, the zinc sheet with a thickness of 0.15 mm is the negative electrode, and the mixed aqueous solution prepared in Example 1 is the electrolyte solution to assemble the battery. After testing, the charge-discharge curve of the prepared high-voltage mixed-ion secondary battery under 15mA / g constant current is as follows: Figure 5 shown.

Embodiment 3

[0031] After mixing zinc powder, porous carbon material activated carbon, conductive agent acetylene black, binder polytetrafluoroethylene and corrosion inhibitor indium oxide in a mass ratio of 50:20:20:9:1, press it on the current collector stainless steel mesh , cut to a certain size, and dried in a vacuum to obtain a zinc electrode.

[0032] The zinc electrode is used as the negative electrode, and the quality of the zinc powder is LiFe 0.3 mn 0.7 PO 4 Ten times of quality, with the LiFe that embodiment 2 makes 0.3 mn 0.7 PO 4 The electrode sheet is the positive electrode, and the mixed aqueous solution prepared in Example 1 is the electrolyte solution to assemble the battery. After testing, the charge-discharge curve of the prepared high-voltage mixed-ion secondary battery under 15mA / g constant current is as follows: Image 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com