Method for producing iron lithium manganese phosphate composite positive electrode material used in lithium ion battery through carbon reduction

A composite positive electrode material, lithium manganese iron phosphate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low electronic conductivity and ion diffusion rate, low discharge voltage platform, and limit the electrochemical performance of positive electrode materials. Achieve the effects of low material cost, short production cycle and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

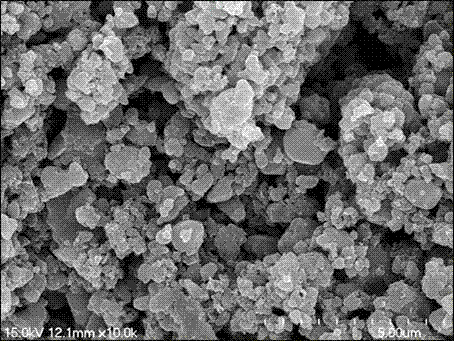

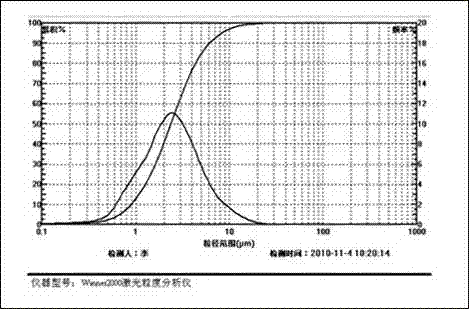

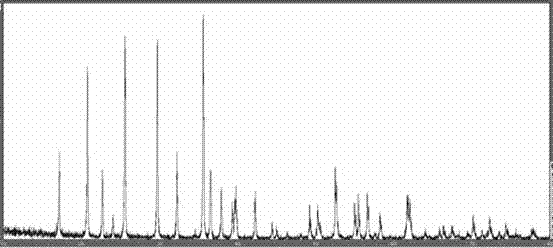

Embodiment 1

[0023] Take a certain amount of iron orthophosphate (FePO 4 ﹒ 2H 2 O), bake at 450°C for 5 hours, and measure the iron content by removing all crystal water in theory. Weigh the FePO with the water of crystallization removed 4 , Li 2 CO 3 、TiO 2 , Nb 2 o 5、 MnCO with a small amount of rare earth 3 , LiH 2 PO 4 , glucose, FePO 4 , Li 2 CO 3 、TiO 2 , Nb 2 o 5 , MnCO 3 , LiH 2 PO 4The molar ratio is 1.8:0.89:0.02:0.01:0.2:0.2, 12% glucose is added to the total mass of lithium carbonate and iron phosphate, and they are put into a roller mill with zirconium ball media and mixed for 5 hours, and the raw materials are mixed After uniformity, put it into the sagger and send it to the atmosphere furnace with nitrogen gas. The atmosphere furnace heats up at a rate of 300 ° C per hour. When the temperature reaches 400 ° C, it is roasted at a constant temperature for 2 hours, and then the temperature is raised again. When the temperature reaches 750 ° C Calcined at con...

Embodiment 2

[0025] Take a certain amount of iron orthophosphate (FePO 4 ﹒ 2H 2 O), bake at 450°C for 5 hours, and measure the iron content by removing all crystal water in theory. Weigh the FePO with the water of crystallization removed 4 , Li 2 CO 3 , MnCO containing a small amount of rare earth 3 , LiH 2 PO 4 , glucose, FePO 4 , Li 2 CO 3 , MnCO 3 , LiH 2 PO 4 The molar ratio is 1.8:0.875:0.2:0.2. Add 12% glucose relative to the total mass of lithium carbonate and iron phosphate, and put them into a roller mill with zirconium ball media and mix them for 5 hours. After the raw materials are mixed evenly, load Put it into the sintered sagger, and send it to the atmosphere furnace mixed with nitrogen and carbon dioxide. The atmosphere furnace heats up at a rate of 300 ° C per hour. When the temperature reaches 400 ° C, it is roasted at a constant temperature for 2 hours, and then the temperature is raised again. Roasting at the rear constant temperature for 7h, then naturally...

Embodiment 3

[0027] Take a certain amount of iron orthophosphate (FePO 4 ﹒ 2H 2 O), bake at 450°C for 5 hours, and measure the iron content by removing all crystal water in theory. Weigh the FePO with the water of crystallization removed 4 , Li 2 CO 3 、TiO 2 , Nb 2 o 5、 MnCO with a small amount of rare earth 3 , LiH 2 PO 4 , glucose, FePO 4 , Li 2 CO 3 、TiO 2 , Nb 2 o 5 , MnCO 3 , LiH 2 PO 4 The molar ratio is 1.6: 0.677: 0.02: 0.01: 0.4: 0.4. Add 12% glucose to the total mass of lithium carbonate and iron phosphate, and put it into a roller mill with zirconium ball media. Mix and grind for 5 hours until the raw materials are mixed evenly Finally, put it into the sagger and send it to the nitrogen atmosphere furnace. The atmosphere furnace heats up at a rate of 300 ° C per hour. When the temperature reaches 400 ° C, it is roasted at a constant temperature for 2 hours, and then the temperature is raised again. When the temperature reaches 770 ° C, the temperature is const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com