Surface coating modified lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of non-conductivity of metal compounds, poor conductivity of positive electrode materials, and reduced electrochemical performance of batteries, etc., to achieve excellent safety. performance and cycle performance, improved stability, lower energy consumption and cost effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the molar ratio of Ni:Co:Al of 0.8:0.15:0.05 to prepare a mixed aqueous solution of nickel nitrate, cobalt nitrate and aluminum nitrate nonahydrate with a total metal concentration of 1mol / L; prepare a mixture of NaOH and ammonia with a total concentration of 10mol / L Solution in which the molar ratio of NaOH and ammonia is 1:1.

[0026] Add the above two solutions to the reactor at a certain speed at the same time, control the pH of the reaction to 12, the reaction temperature is 50 ℃, react for 6 hours and then age for 8 hours, after filtering, washing and drying to obtain lithium nickel cobalt aluminate Positive electrode material precursor.

[0027] After mixing the above-mentioned nickel cobalt lithium aluminate cathode material precursor and lithium carbonate uniformly in a ratio of Li:(Ni+Co+Al) of 1.05:1, calcining at 900℃ for 8h, cooling, crushing and sieving to obtain nickel cobalt Lithium aluminate cathode material.

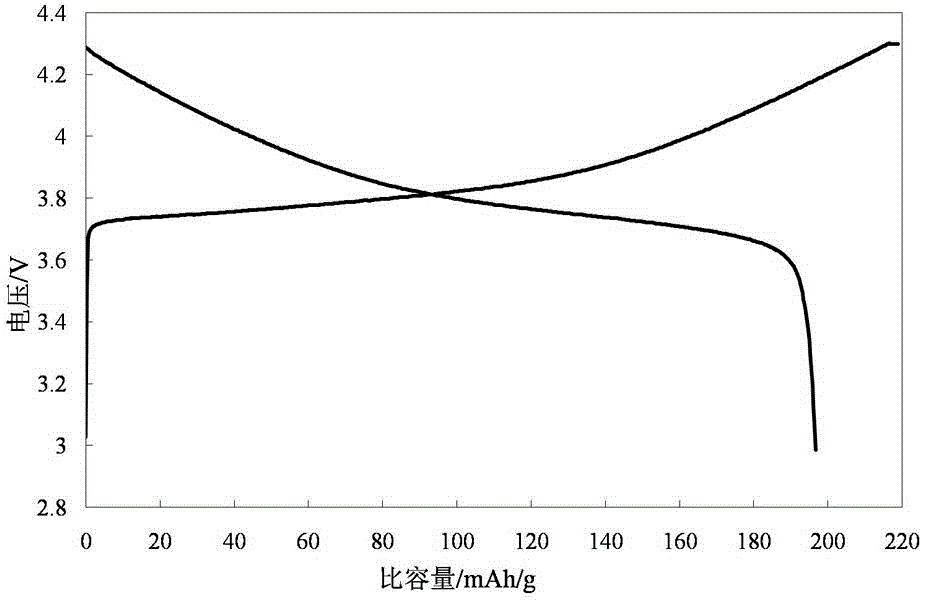

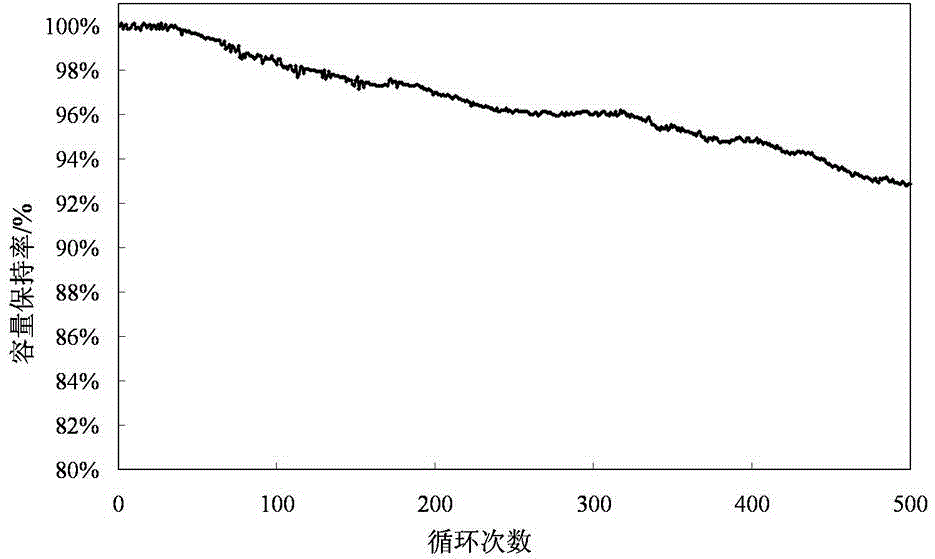

[0028] LiNi 1-a-b Co a Al b O 2 Th...

Embodiment 2

[0031] According to the molar ratio of Ni:Co:Al of 0.8:0.15:0.05 to prepare a mixed aqueous solution of nickel nitrate, cobalt nitrate and aluminum nitrate nonahydrate with a total metal concentration of 1mol / L; prepare a mixture of NaOH and ammonia with a total concentration of 10mol / L Solution in which the molar ratio of NaOH and ammonia is 1:1.

[0032] Add the above two solutions to the reactor at a certain speed at the same time, control the pH of the reaction to 10, the reaction temperature to 50 ℃, and aging for 8 hours after 6 hours of reaction. After filtering, washing and drying, lithium nickel cobalt aluminate is obtained. Positive electrode material precursor.

[0033] After mixing the above-mentioned nickel cobalt lithium aluminate cathode material precursor and lithium carbonate uniformly in a ratio of Li:(Ni+Co+Al) of 1.05:1, calcining at 900℃ for 8h, cooling, crushing and sieving to obtain nickel cobalt Lithium aluminate cathode material.

[0034] LiNi 1-a-b Co a Al...

Embodiment 3

[0036] According to the molar ratio of Ni:Co:Al of 0.85:0.10:0.05, a mixed aqueous solution of nickel nitrate, cobalt nitrate and aluminum nitrate nonahydrate with a total metal concentration of 1mol / L was prepared; a mixture of NaOH and ammonia with a total concentration of 10mol / L was prepared Solution in which the molar ratio of NaOH and ammonia is 1:1.

[0037] Add the above two solutions to the reactor at a certain speed at the same time, control the pH value of the reaction to 11, the reaction temperature is 60 ℃, react for 6 hours and then age for 8 hours. After filtering, washing and drying, lithium nickel cobalt aluminate is obtained. Positive electrode material precursor.

[0038] After mixing the above-mentioned nickel cobalt lithium aluminate cathode material precursor and lithium carbonate uniformly in a ratio of Li:(Ni+Co+Al) of 1.08:1, calcining at 800℃ for 12h, cooling, pulverizing and sieving to obtain nickel cobalt Lithium aluminate cathode material.

[0039] LiNi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com