Carbon coated lithium manganese phosphate/lithium iron phosphate core-shell structure material as well as preparation method thereof

A core-shell structure, lithium manganese phosphate technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of reducing the tap density of materials, unfavorable for large-scale preparation, and unsuitable for large-scale industrial production, and achieves a simple and easy process. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

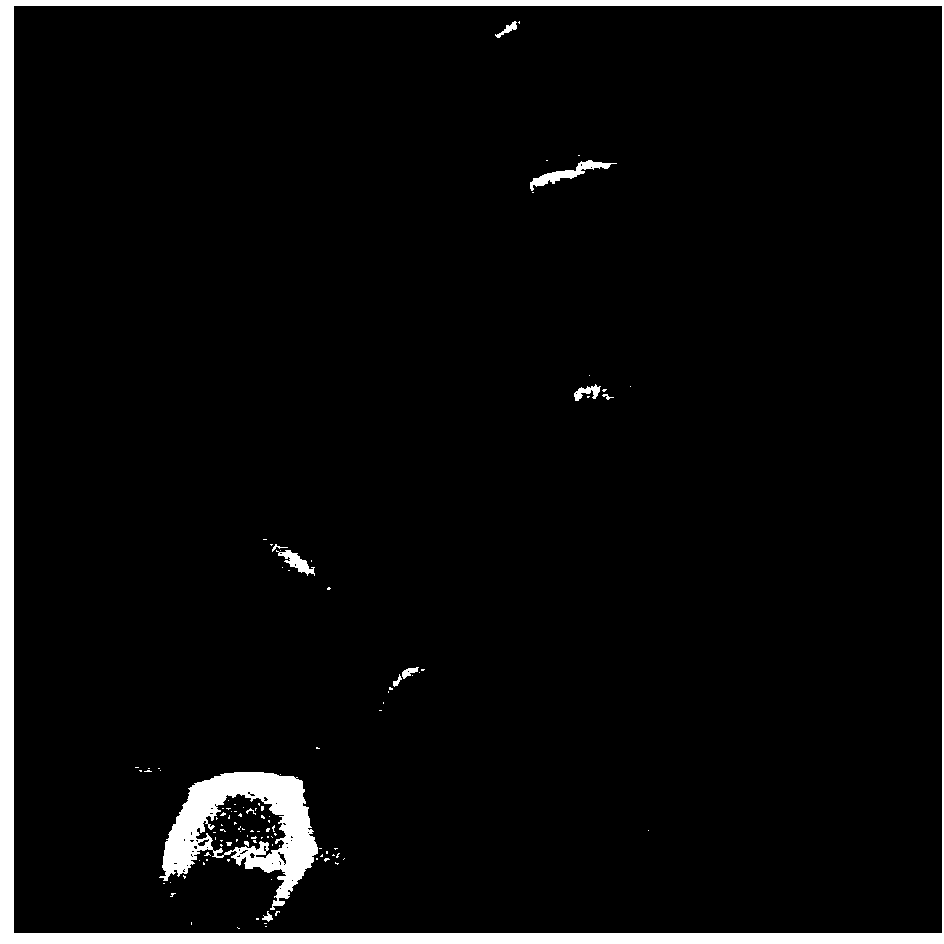

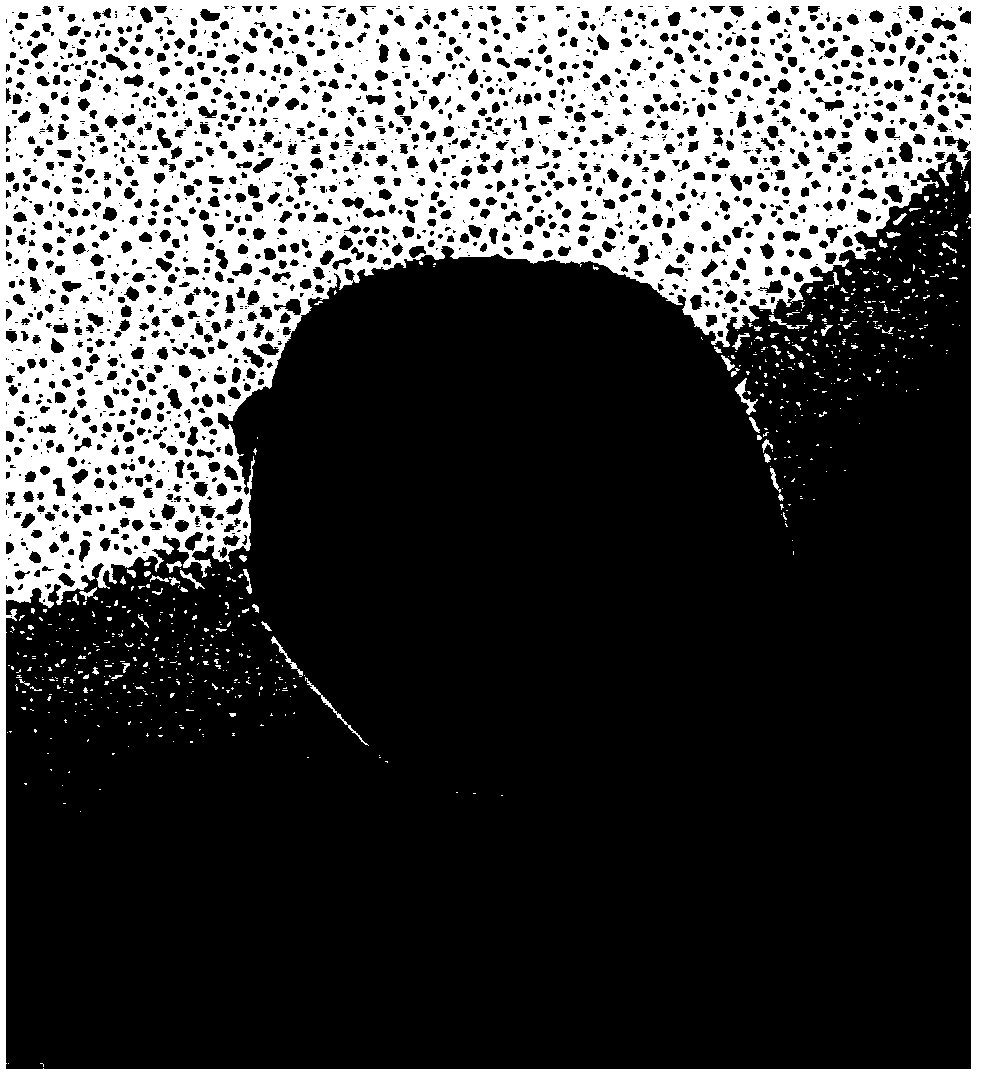

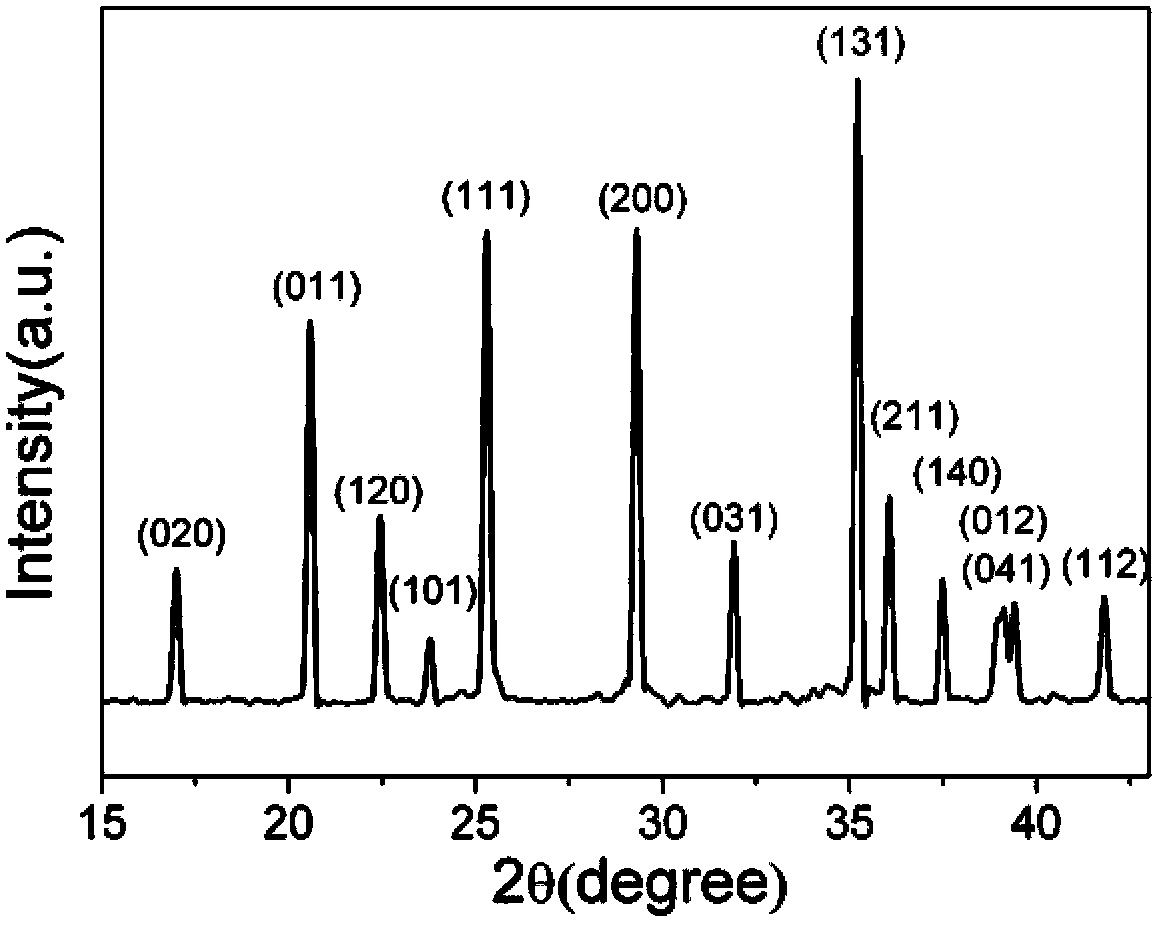

[0044]Weigh 0.03mol manganese carbonate, 0.03mol diammonium hydrogen phosphate, and 0.015mol lithium carbonate according to an equimolar ratio, add them to a corundum ball mill jar, and add an appropriate amount of ethanol, and ball mill them in a vibratory ball mill for 1 hour to obtain the first reaction precursor. The first reaction precursor was heat-treated at 600 °C for 5 hours in an Ar flow to obtain LiMnPO 4 Materials, scanning electron microscope photographs (SEM) of samples such as figure 1 As shown, the particle size is between 300-500nm, and the transmission electron micrograph (TEM) of the sample is shown as figure 2 It can be seen that the particle surface is relatively smooth. Weigh 1.5g LiMnPO 4 With 0.91g iron phosphate (FePO 4 4H 2 O), 0.186g lithium hydroxide (LiOH·H 2 O), 0.5g of glucose were mixed, and 5mL of ethanol ball milling was added to obtain the second reaction precursor. The second reaction precursor was heat-treated at 600°C for 10 hours i...

Embodiment 2

[0047] Weigh 0.03 mol of manganese carbonate, 0.03 mol of diammonium hydrogen phosphate, and 0.015 mol of lithium carbonate, put them into a corundum ball mill jar, add 5 mL of ethanol, and mill in a planetary ball mill for 6 hours to prepare a lithium manganese phosphate reaction precursor. The reaction precursor was heat-treated at 600 °C for 5 hours in Ar flow to prepare LiMnPO 4 Material. Weigh 1.5g LiMnPO 4 , with 0.91g iron phosphate (FePO 4 4H 2 O), 0.161g lithium carbonate (Li 2 CO 3 ), 0.4 g of glucose were mixed, and ball milled to obtain a reaction precursor. The reaction precursor was heat-treated at 600°C for 10 hours in an Ar flow to obtain the target product, and the target product was characterized by the same method as in Example 1, and it was confirmed that the target product was LiFePO 4 Coated LiMnPO 4 The material, the molar ratio of Mn:Fe in the composite material is 7:3. By adopting the same method as in Example 1, the first discharge specific ca...

Embodiment 3

[0049] Weigh 0.03mol of manganese carbonate, 0.03mol of diammonium hydrogen phosphate, and 0.015mol of lithium carbonate, and mix them uniformly by ball milling to prepare a lithium manganese phosphate reaction precursor. The reaction precursor was heat-treated at 600 °C for 5 hours in Ar flow to prepare LiMnPO 4 Material. Weigh 1.5g LiMnPO 4 , with 1.82g iron phosphate (FePO 4 4H 2 O), 0.372g lithium hydroxide, 1.29g sucrose are mixed, and ball milling makes reaction precursor. The reaction precursor was heat-treated at 600°C for 10 hours in an Ar flow to obtain the target product, and the target product was characterized by the same method as in Example 1, and it was confirmed that the target product was LiFePO 4 Coated LiMnPO 4 The material, the molar ratio of Mn:Fe in the composite material is 54:46. The inner core is LiMnPO prepared by the first solid-phase reaction 4 , the size is about 300nm, the outer core is composed of lithium iron phosphate particles of about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com