Lithium manganese phosphate or lithium manganese silicate power cell, positive and negative pole manufacturing method thereof

A technology of lithium manganese silicate and lithium manganese phosphate, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as deformation, insufficient discharge capacity of lithium batteries, unsafe batteries, etc., and achieve high safety and good rate Discharge capability, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

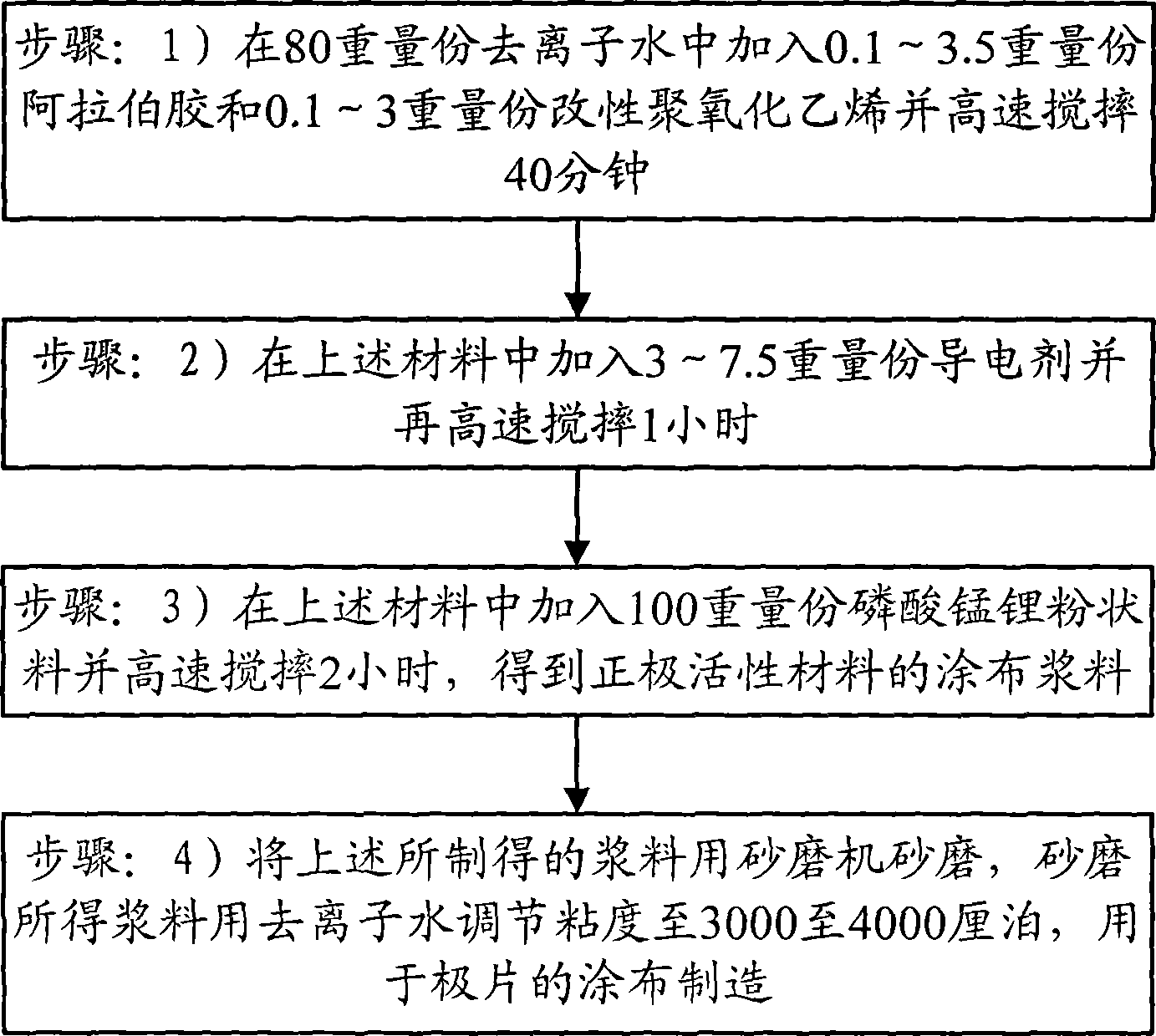

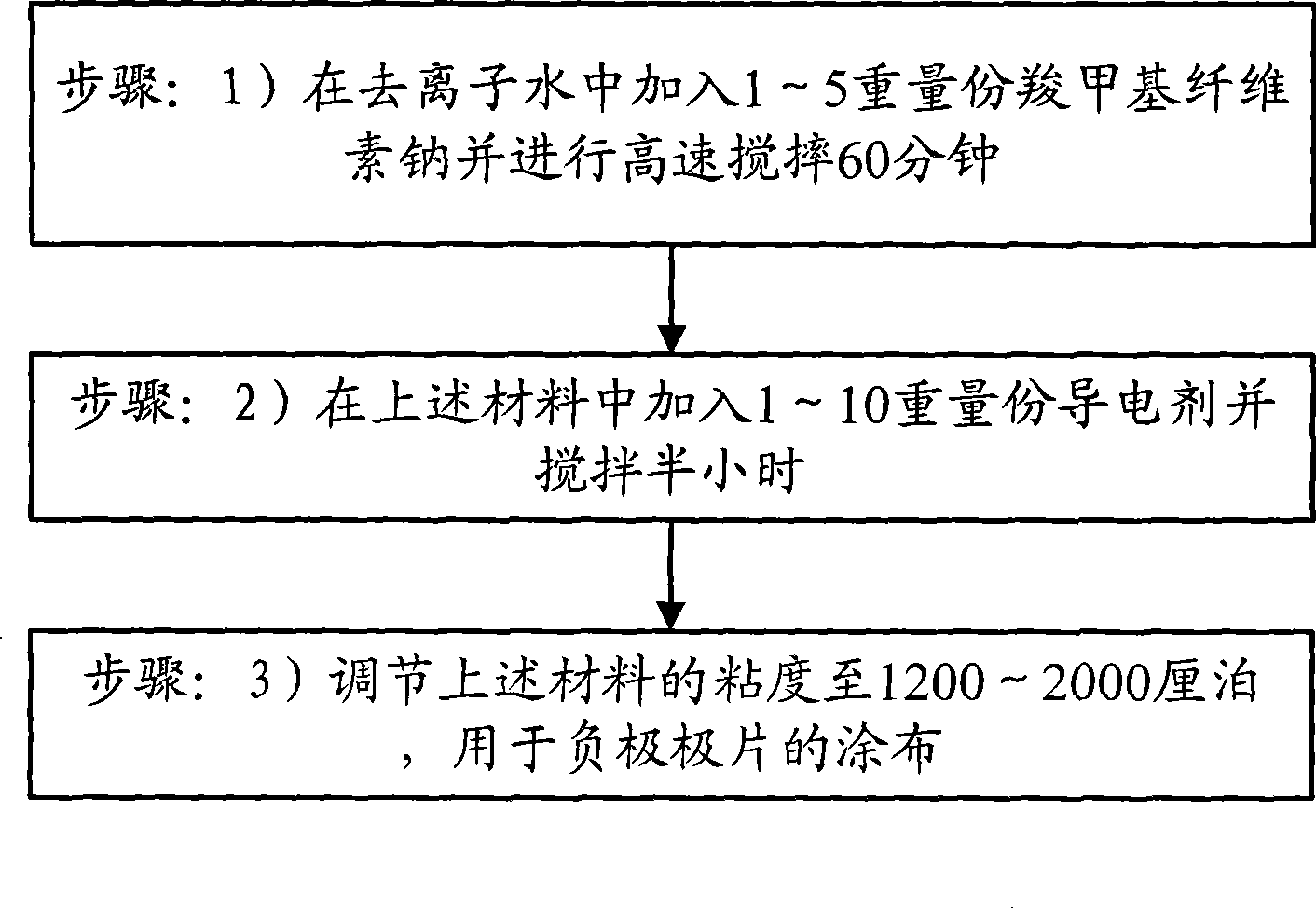

Method used

Image

Examples

Embodiment Construction

[0024] The inventor's research has found that the discharge voltage platform of lithium ferrous phosphate and graphite negative electrode is 3.2V, and the discharge voltage platform of lithium ferrous phosphate (lithium manganese silicate) and lithium titanate is 2.2V; Lithium (lithium manganese silicate) is combined with graphite negative electrode and lithium titanate to form a battery whose discharge voltage platforms are 4.0V and 3.2V respectively.

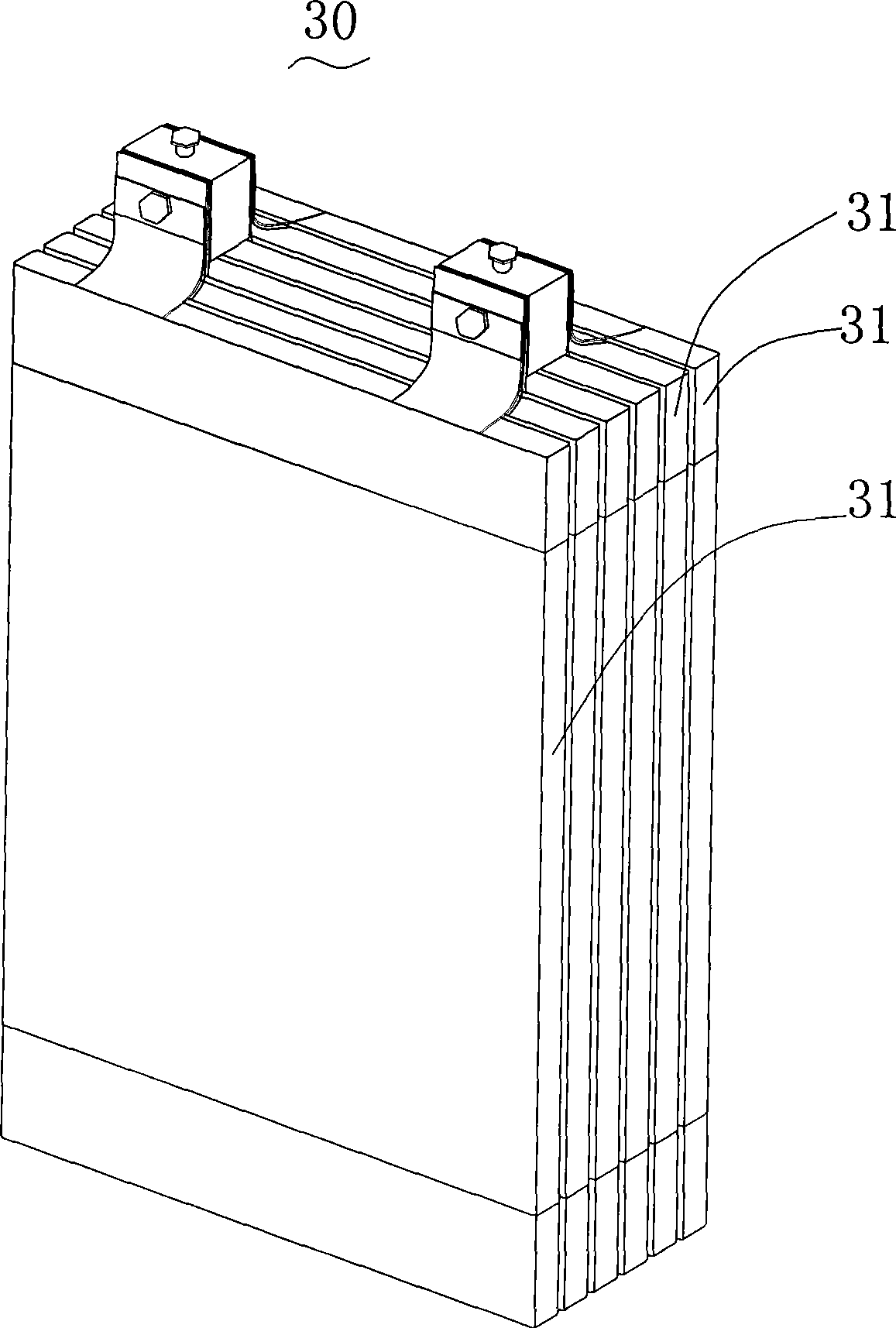

[0025] Therefore, the present invention provides a lithium manganese phosphate or lithium manganese silicate power battery, comprising a positive electrode and a negative electrode, the preparation material of the positive electrode includes lithium manganese phosphate or lithium manganese silicate; the preparation material of the negative electrode includes lithium titanate .

[0026] The present invention proposes for the first time to use lithium manganese phosphate or lithium manganese silicate positive electrode and lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com