Fitting method of transmission case cover

A transmission case cover and part assembly technology, which is applied in the directions of transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems such as the deformation of the main shaft bearing hole, the larger radial runout, etc., to ensure the quality of the parts assembly. , The effect of reducing radial runout and avoiding deformation of the spindle bearing hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

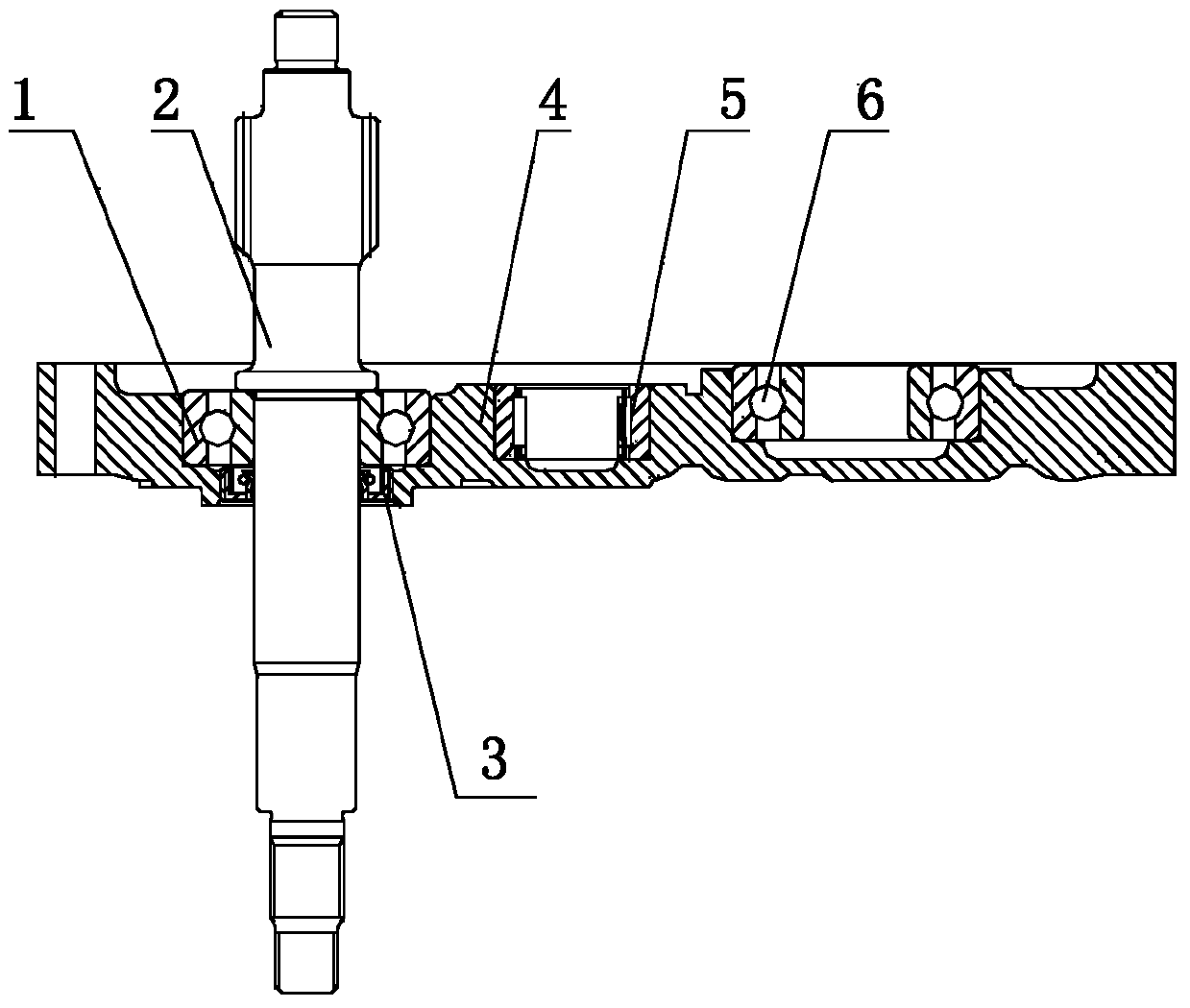

[0025] Such as figure 1 As shown, to partially install the engine transmission case cover, it is necessary to install the main shaft bearing 1, the main shaft 2, the main shaft oil seal 3, the wheel shaft bearing 5 and the drive shaft bearing 6 on the corresponding positions of the transmission case cover 4.

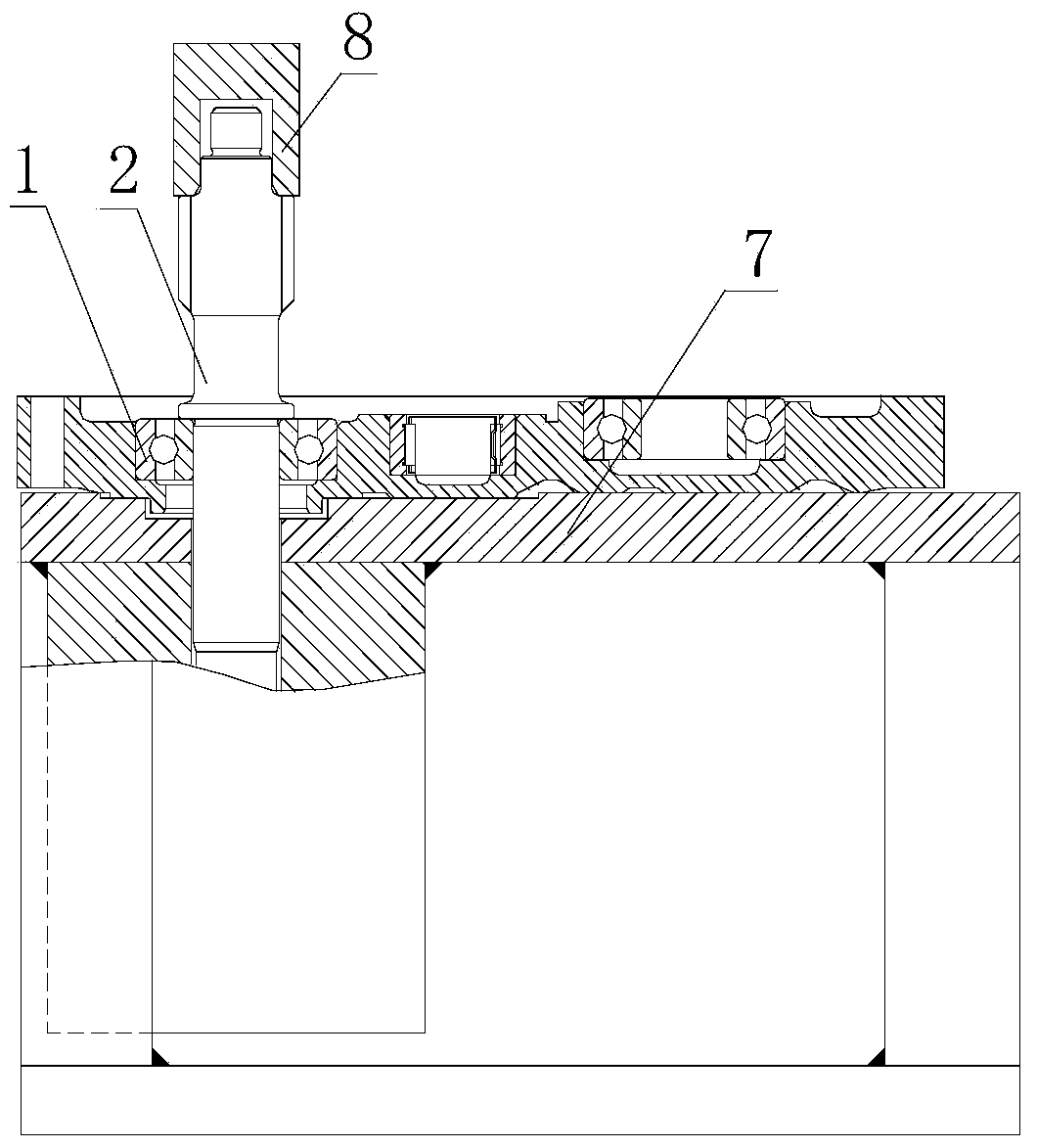

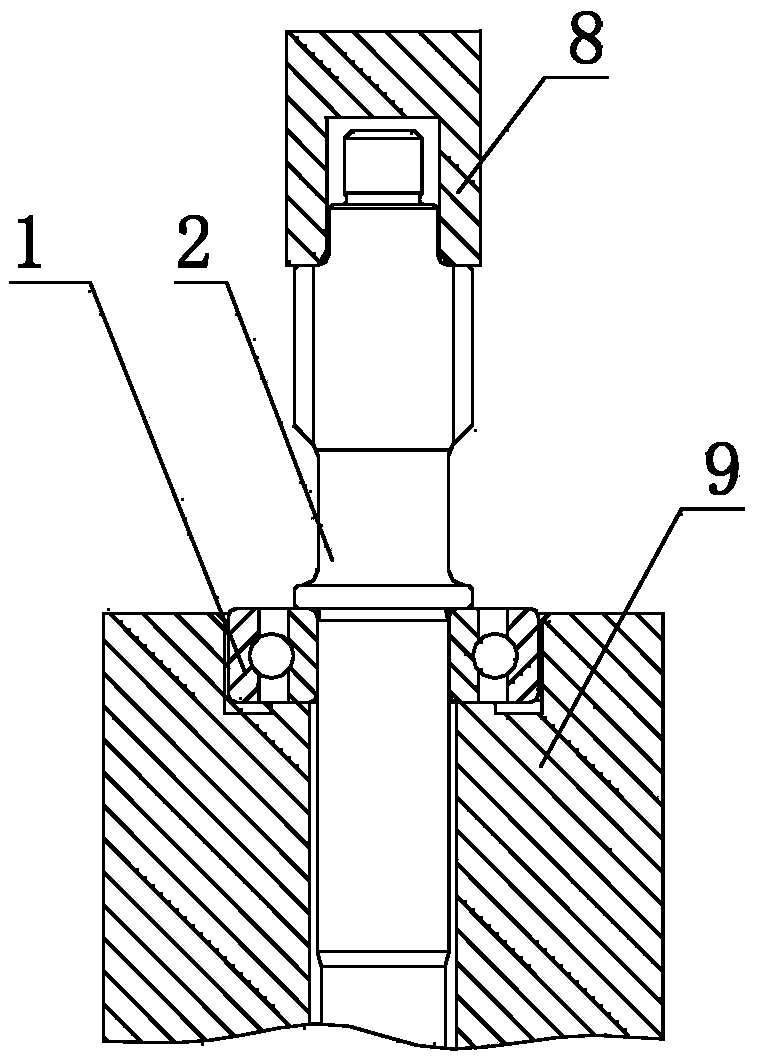

[0026] Such as image 3 and 4 Shown, the engine transmission box cover part adornment method of the present invention may further comprise the steps:

[0027] Step 1. Place the main shaft bearing 1 on the bearing support seat 9, then put the main shaft 2 into the inner hole of the main shaft bearing 1, press the main shaft 2 into the hole of the main shaft bearing 1 through the pressure head, and complete the main shaft bearing 1 and the main shaft 2; in this step, the indenter adopts the short indenter 8, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com