A kind of preparation method of linixmn2-xo4 cathode material

A cathode material and lithium source technology, which is applied in the field of cathode materials for lithium ion batteries, can solve the problems of deteriorating the cycle performance of materials, aggravating the oxidation and decomposition of electrolytes, etc., and achieves the effects of reduced energy consumption, good cycle performance, and small specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

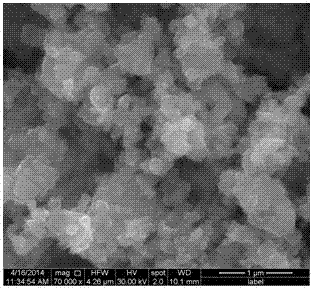

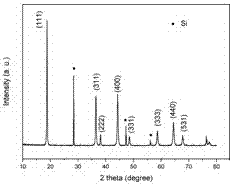

[0022] The LiNi 0.5 mn 1.5 o 4 The preparation method of cathode material, its specific steps are as follows:

[0023] (1) First, ball mill and mix the lithium source, nickel source, manganese source and auxiliary agent for 1 hour, and then o The precursor is prepared by drying under C conditions, wherein the molar ratio of the lithium source, the nickel source and the manganese source is 1.0:0.5:1.5, and at least one of the lithium source, the nickel source, the manganese source and the auxiliary agent is a chloride; wherein the lithium The source is LiCl·H 2 O, 0.1mol; Ni source is NiCl 2 ·6H 2 O, 0.05 mol; manganese source is MnCl 2 4H 2 O, 0.15mol; auxiliary agent is oxalic acid, 0.3mol;

[0024] (2) The precursor obtained in step (1) was pressed at 20 o C / min rate heating up to 500 o C is heated at constant temperature for 10h, then cooled to room temperature, and the product after cooling is LiNi 0.5 mn 1.5 o 4 Cathode material.

[0025] Comparative test (r...

Embodiment 2

[0031] The LiNi 0.5 Mn 1.5 O 4 The preparation method of positive electrode material, its specific steps are as follows:

[0032] (1) First, the lithium source, nickel source, manganese source and auxiliary agent are ball-milled and mixed for 3h, and then at 100 o The precursor is prepared by drying under the condition of C, wherein the molar ratio of lithium source, nickel source and manganese source is 1.0:0.5:1.5, and at least one of lithium source, nickel source, manganese source and auxiliary agent is chloride; wherein lithium source The source is LiOH·H 2 O, 0.1 mol; Ni source is NiO, 0.05 mol; Manganese source is MnCl 2 ·4H 2 O, 0.15 mol; auxiliary agent is oxalic acid, 0.25 mol;

[0033] (2) Press the precursor obtained in step (1) to press 10 in an air atmosphere o C / min rate ramp up to 600 o C constant temperature heating for 10h, then cooled to room temperature, the product after cooling is LiNi 0.5 Mn 1.5 O 4 positive electrode material.

Embodiment 3

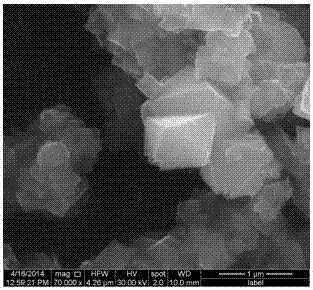

[0035] The LiNi 0.5 Mn 1.5 O 4 The preparation method of positive electrode material, its specific steps are as follows:

[0036] (1) First, the lithium source, nickel source, manganese source and auxiliary agent are ball-milled and mixed for 3h, and then at 80 o The precursor is prepared by drying under the condition of C, wherein the molar ratio of lithium source, nickel source and manganese source is 1.0:0.5:1.5, and at least one of lithium source, nickel source, manganese source and auxiliary agent is chloride; wherein lithium source Source is Li 2 CO 3 , 0.05mol; nickel source is NiO, 0.05mol; manganese source is MnCl 2 ·4H 2 O, 0.15 mol; auxiliary agent is ammonium oxalate, 0.15 mol;

[0037] (2) Press the precursor obtained in step (1) to press 20 in an air atmosphere o C / min rate ramp up to 700 o C constant temperature heating for 10h, then cooled to room temperature, the product after cooling is LiNi 0.5 Mn 1.5 O 4 positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com