Method for preparing low-temperature lithium ion battery hard carbon negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in the field of lithium ion batteries, can solve the problem of too tight material microstructure, and achieve the effects of excellent electrochemical performance, simple process and low specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

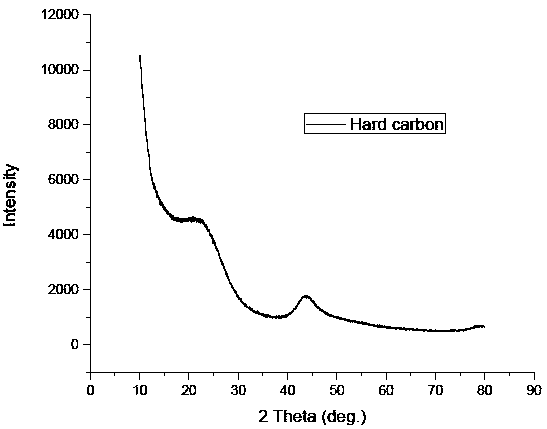

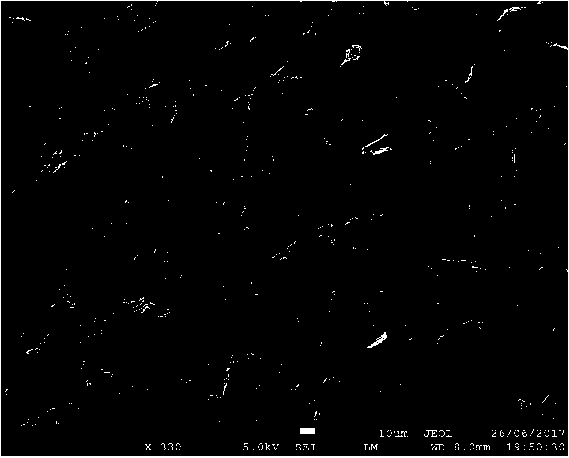

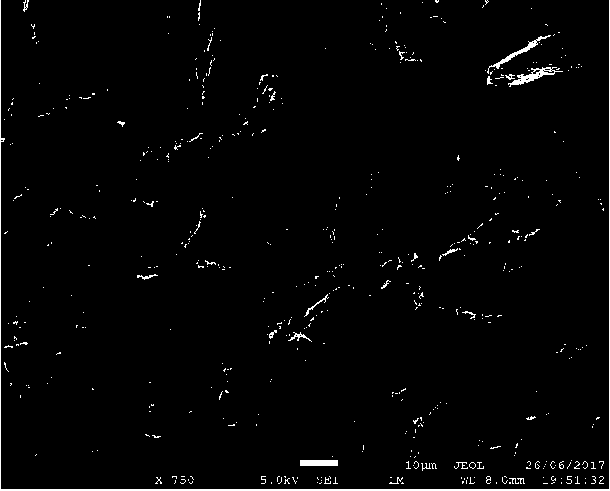

Image

Examples

Embodiment 1

[0028] A kind of method for preparing lithium ion battery hard carbon negative electrode material of the present invention, carry out according to the following steps:

[0029] (1) Weigh 1000g block anthracite, wash it with water, dry it at 100°C for 10h in a blast drying oven, then take it out and place it in the air for cooling;

[0030] (2) After pulverizing the massive anthracite obtained in the step (1), put it into an alumina crucible, place the crucible in a high-temperature furnace, and first feed nitrogen to discharge the air in the furnace;

[0031] (3) Heat the high-temperature furnace to 1300 °C at a heating rate of 1.5 °C / min. During the heating process, adjust the gas valve to N at a ratio of 0.1:1. 2 mixed with CO 2 , forming a mixed gas, and then passing the mixed gas into the high-temperature furnace, the flow rate of the mixed gas is 100 mL / min; the pyrolysis time is 5h; and the hard carbon negative electrode material is obtained after cooling.

Embodiment 2

[0033] A kind of method for preparing lithium ion battery hard carbon negative electrode material of the present invention, carry out according to the following steps:

[0034] (1) Weigh 1000g of bulk graphite, wash it with water, dry it at 130°C for 9 hours in a blast drying oven, then take it out and place it in the air for cooling;

[0035] (2) After pulverizing the massive graphite obtained in the step (1), put it into an alumina crucible, place the crucible in a high-temperature furnace, and first feed nitrogen to discharge the air in the furnace;

[0036] (3) Heat the high-temperature furnace to 1400°C at a heating rate of 2°C / min. During the heating process, adjust the gas valve to N at a ratio of 0.08:1. 2 mixed with CO 2 , forming a mixed gas, and then passing the mixed gas into the high-temperature furnace, the flow rate of the mixed gas is 200 mL / min; the pyrolysis time is 4h; the pyrolysis time is 5h; the hard carbon negative electrode material is obtained after c...

Embodiment 3

[0038] A kind of method for preparing lithium ion battery hard carbon negative electrode material of the present invention, carry out according to the following steps:

[0039] (1) Weigh 1000g of wood, wash it with water, dry it in a blast drying oven at 160°C for 8 hours, then take it out and place it in the air for cooling;

[0040] (2) After the wood gained in the step (1) is pulverized, it is packed into an alumina crucible, the crucible is placed in a high-temperature furnace, and nitrogen gas is first introduced to discharge the air in the furnace;

[0041] (3) Heat the high-temperature furnace to 1500 °C at a heating rate of 2.5 °C / min. During the heating process, adjust the gas valve to N at a ratio of 0.06:1. 2 mixed with CO 2 , forming a mixed gas, and then passing the mixed gas into a high-temperature furnace, the flow rate of the mixed gas is 300 mL / min; the pyrolysis time is 3 h; and the hard carbon negative electrode material is obtained after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com