Production process of lithium battery negative electrode material

A negative electrode material and production process technology, which is applied in the production process field of lithium battery negative electrode materials, can solve the problems of poor uniformity of the coating layer, failure to meet energy saving and emission reduction, and low carbonization yield, so as to increase the carbonization yield and improve stability performance and other properties, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A production process of a lithium battery negative electrode material, comprising the following production steps:

[0032] The first step is to prepare artificial graphite:

[0033] Remove impurities, purify the coal tar so that its quinoline insoluble content is less than 0.05%, and then use this as a raw material to prepare coal tar, which is catalytically modified to remove sulfur, nitrogen and quinoline in the coal tar. After insoluble matter, modified coal pitch is obtained, the softening point of modified coal pitch is 80°C, the coking value is 55%, and the content of quinoline insoluble matter is less than 0.01%;

[0034] Coking, coking the modified coal pitch at 510°C and calcining at 800°C to obtain homogenous coke;

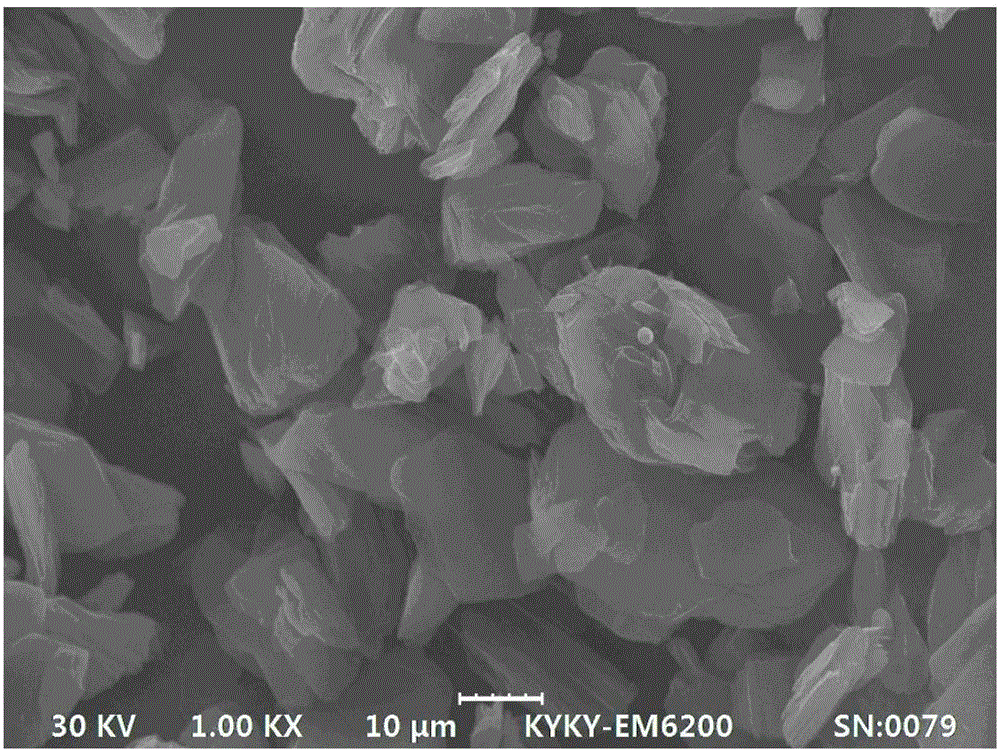

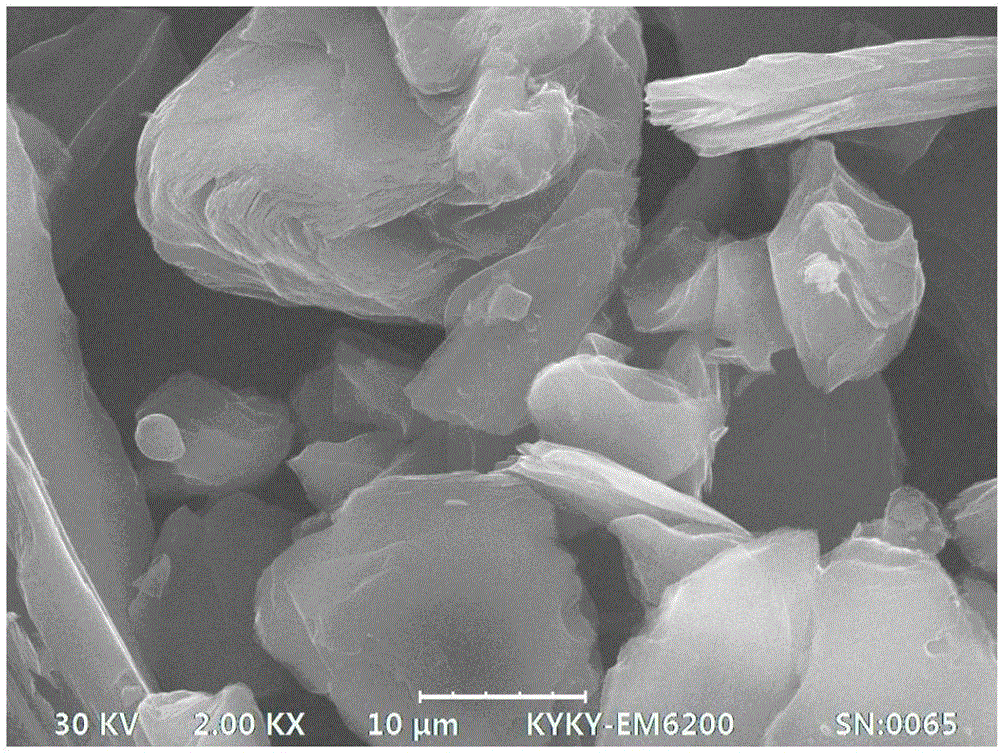

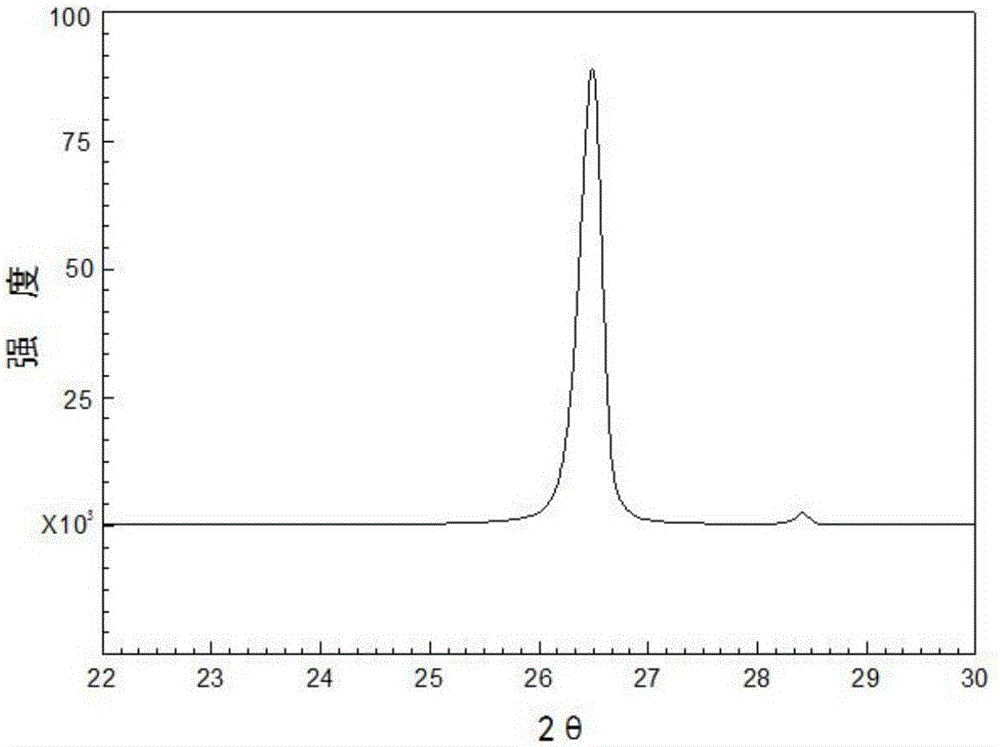

[0035] Shaping, crushing and sieving the homogenous coke, then shaping, to obtain cobble-shaped coke powder with an aspect ratio of 1-1.5 (shape such as figure 1 As shown, the phase structure is as figure 2 shown);

[0036] Graphitization, th...

Embodiment 2

[0042] A production process of a lithium battery negative electrode material, comprising the following production steps:

[0043] The first step is to prepare artificial graphite:

[0044] Remove impurities, purify the coal tar so that its quinoline insoluble content is less than 0.05%, and then use this as a raw material to prepare coal tar, which is catalytically modified to remove sulfur, nitrogen and quinoline in the coal tar. After insoluble matter, modified coal pitch is obtained, the softening point of modified coal pitch is 100°C, the coking value is 45%, and the content of quinoline insoluble matter is less than 0.01%;

[0045] Coking, coking the modified coal pitch at 550°C and calcining at 700°C to obtain homogenous coke;

[0046] Shaping, crushing and sieving the homogenous coke and shaping to obtain cobble-shaped coke powder with an aspect ratio of 1-1.5;

[0047] Graphitization, the coke powder is graphitized to obtain artificial graphite, and the graphitizatio...

Embodiment 3

[0053] A production process of a lithium battery negative electrode material, comprising the following production steps:

[0054] The first step is to prepare artificial graphite:

[0055] Remove impurities, purify the coal tar so that its quinoline insoluble content is less than 0.05%, and then use this as a raw material to prepare coal tar, which is catalytically modified to remove sulfur, nitrogen and quinoline in the coal tar. After insoluble matter, modified coal pitch is obtained, the softening point of modified coal pitch is 90°C, the coking value is 50%, and the content of quinoline insoluble matter is less than 0.01%;

[0056] Coking, coking the modified coal pitch at 530°C and calcining at 750°C to obtain homogenous coke;

[0057] Shaping, crushing and sieving the homogenous coke and shaping to obtain cobble-shaped coke powder with an aspect ratio of 1-1.5;

[0058] Graphitization, the coke powder is graphitized to obtain artificial graphite, and the graphitization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| coking value | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com